金屬頂刊雙語導讀丨Acta Mater. Vol.199,15 Oct. 2020(上)

2020-10-14 來源: Goal Science

本期包含金屬材料領域論文17篇,涵蓋了316L不銹鋼、3D打印、高熵合金、鈦合金、納米合金、高溫合金、雙相不銹鋼等,國內科研單位包括浙江大學、臺灣國立清華大學等(通訊作者單位)。

Vol. 199 目錄

ACTA Vol. 199,15 Oct. 2020, P19-33

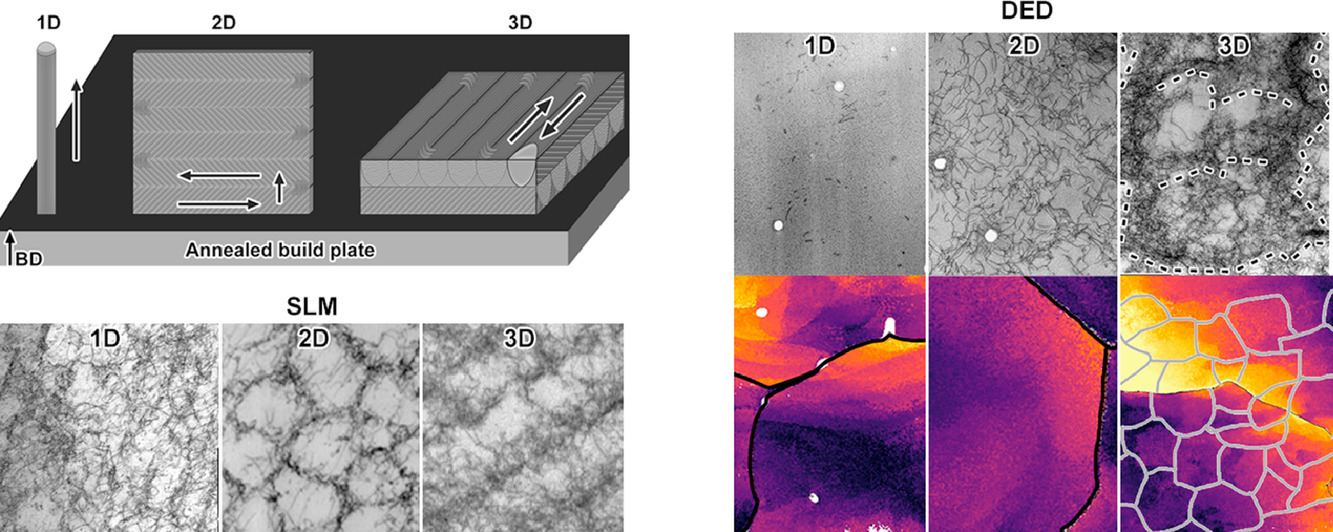

1. Origin of dislocation structures in an additively manufactured austenitic stainless steel 316L

增材制造316L不銹鋼中位錯結構的起源

K.M. Bertsch?, G. Meric de Bellefon, B. Kuehl, D.J. Thoma

K.M. Bertsch:bertsch5@llnl.gov

https://doi.org/10.1016/j.actamat.2020.07.063

摘要

本實驗首次通過幾何約束方法對增材制造不銹鋼中的熱應力進行了控制,從而系統研究了位錯組織的起源。我們制備了桿、壁和矩形棱柱等多種不同維度的316L不銹鋼零件,評估了熱膨脹/收縮對缺陷組織形成的影響,在此基礎上闡明增材制造過程中位錯微觀組織的起源。我們對使用直接能量沉積(DED)和選區激光熔化(SLM)兩種方法制備的多維度組件中的位錯密度、組織、偏析、析出相和錯配進行了比較分析。發現在DED方法制備的部件中,位錯密度與局部錯配和偏析無關,但在一維部件中ρ⊥約為1012m−2,而在三維部件中則上升到了約1014m−2。在DED和SLM制備的三維部件中的高位錯密度與組織中形成了約300-450nm的位錯胞有關。在某些情況下,位錯胞與枝晶偏析重疊。這些結果表明,枝晶偏析、析出相和局部錯配對加工過程中的位錯結構有一定影響,但并不是導致有序的胞狀結構的直接原因。位錯結構是增材制造過程中的熱變形導致的,主要受到熔池周圍的約束條件和熱循環控制。

英文摘要

In this experiment, the origin of dislocation structures in AM stainless steels was systematically investigated by controlling the effect of thermal stress through geometric constraints for the first time. Stainless steel 316L parts were produced in the form of “1D” rods, “2D” walls, and "3D" rectangular prisms to evaluate the effect of constraints to thermal expansion/shrinkage on the development of defect microstructures and to elucidate the origin of additively manufactured (AM) dislocation microstructures. Dislocation density, organization, chemical micro-segregation, precipitate structures, and misorientations were analyzed as a function of increasing constraints around solidifying material in 1D, 2D, and 3D components built using both directed energy deposition (DED) and powder-bed selective laser melting (SLM). In DED parts, the dislocation density was not dependent on local misorientations or micro-segregation patterns, but evolved from approximately ρ⊥=1012m−2 in 1D parts to ρ⊥=1014m−2 in 3D parts, indicating that it is primarily thermal distortions that produce AM dislocation structures. In DED 3D parts and SLM parts, dislocation densities were highest (ρ⊥≈1014m-2) and corresponded to the formation of dislocation cells approximately 300-450 nm in diameter. Dislocation cells overlapped with dendrite micro-segregation in some but not all cases. The results illustrate that dendritic micro-segregation, precipitates, or local misorientations influence how the dislocations organize during processing, but are not responsible for producing the organized cell structures. This work shows that AM dislocation structures originate due to thermal distortions during printing, which are primarily dictated by constraints surrounding the melt pool and thermal cycling.

ACTA Vol. 199, 15 Oct. 2020, P42-52

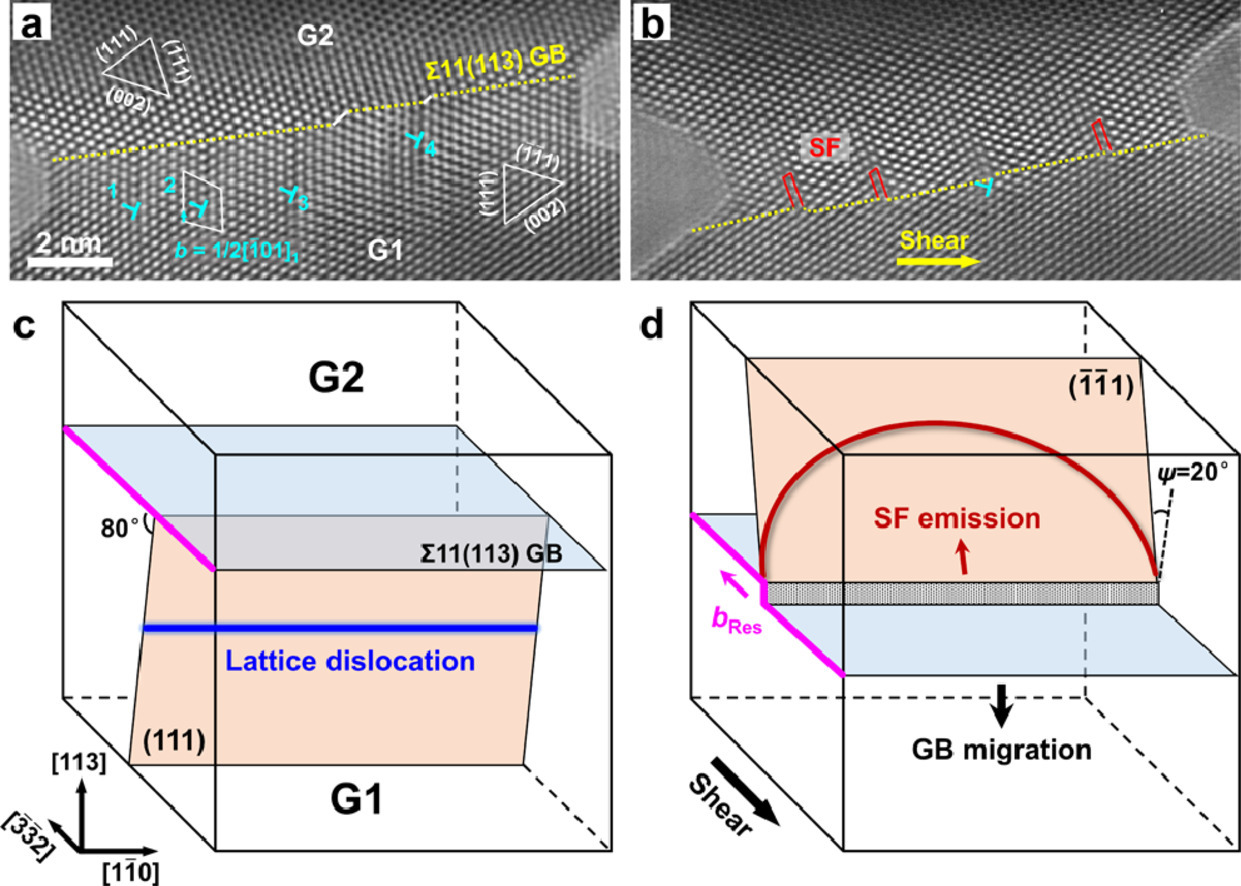

2. In situ atomistic observation of grain boundary migration subjected to defect interaction

缺陷相互作用下晶界遷移的原位原子觀察

Q. Zhu, S.C. Zhao, C. Deng?, X.H. An, K.X. Song, S.X. Mao?, J.W. Wang?

C. Deng:Chuang.Deng@umanitoba.ca,浙江大學

S.X. Mao:sxm2@pitt.edu

J.W. Wang:jiangwei_wang@zju.edu.cn

https://doi.org/10.1016/j.actamat.2020.08.021

摘要

晶粒長大和再結晶都可以被視作是晶界遷移的結果。晶界遷移的過程中常常會遇到晶格缺陷,而這兩者相互作用的原子層面動態機制仍不清晰。因此在本文中,我們通過結合原位納米機械測試和分子動力學模擬系統地研究了Au移動中的Σ11(113)對稱傾側晶界和不同晶格缺陷(包括全位錯、層錯和納米孿晶)之間的相互作用機制。實驗表明,在局部原子位移控制晶界-缺陷相互作用的條件下,Σ11 (113)GB表現出一種保守的缺陷容納機制和與之耦合的晶界-孿晶演化。此外,切變耦合的晶界遷移不受缺陷的影響,因為晶界上含有可滑動斷點。這些發現為晶界在不同晶格缺陷影響下的原子尺度遷移機制提供了全面的實驗理解,極大推動了晶界主導塑性理論的發展。

英文摘要

Grain boundary (GB) migration associated with grain growth and recrystallization encounters lattice defects frequently, while the atomistic mechanisms of GB-defect interactions during these dynamic processes remain largely unclear. Here, we systematically investigate the atomistic mechanism of the interactions between migrating Σ11(113) symmetrical tilt GBs and different lattice defects, including full dislocation, stacking fault and nanotwin in Au, via the integrated in situ nanomechanical testing and molecular dynamics simulations. Experimental evidence demonstrated a conservative defect accommodation mechanism of Σ11(113) GB and a coupled GB-twin evolution, where localized atom displacement dominated the GB-defect interactions. Moreover, the shear-coupled GB migration was unperturbed by the interaction, due to the glissile residual disconnections left on the GB. These findings provide a comprehensive experimental understanding on the atomistic mechanism of GB migration under the influence of different lattice defects, which significantly advances the theoretical development of GB-dominated plasticity under more realistic circumstances.

ACTA Vol. 199, 15 Oct. 2020, P53-62

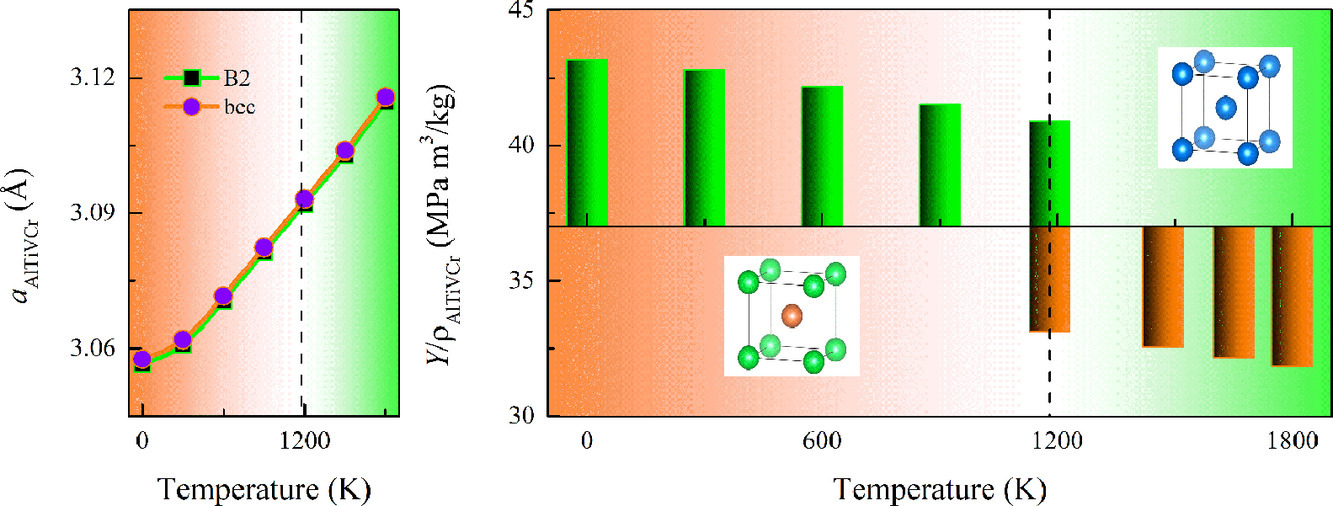

3. Chemical ordering controlled thermo-elasticity of AlTiVCr1-xNbx high-entropy alloys

AlTiVCr1-xNbx 高熵合金中由化學有序控制的熱彈性研究

Shuo Huang?, Wei Li, Olle Eriksson, Levente Vitos?

S. Huang:shuoh@kth.se

L. Vitos:levente@kth.se

https://doi.org/10.1016/j.actamat.2020.08.005

摘要

多組元體系中各組成相的穩定性極大地影響材料在高溫下的機械性能。在本研究中,我們重點研究了BCC結構的AlTiVCr1-xNbx (0 ≤ x ≤ 1)合金中的化學有序。對于合金元素分布的第一性原理計算表明體系中存在B2型部分有序結構。我們作出了無序和部分有序相的彈性參數隨成分和溫度的變化圖。我們發現體系對于有序無序轉變十分敏感,尤其是富Cr體系。對于體系有序程度的合理調控可以改善材料的機械性能,同時保持材料的密度不變。我們進一步對可能具有高比強度、低熱膨脹和高彈性軟化抗性的合金體系進行了預測,這些材料的熱機械性能有望和高溫合金以及其他高溫結構材料進行競爭。

英文摘要

The stability of constituent phases in multi-component system always plays a prominent role in tailoring their mechanical performance at elevated temperatures. In this work, we highlight a chemical ordering feature in the AlTiVCr1-xNbx (0 ≤ x ≤ 1) alloys with body-centered cubic crystal structure. The quantum-mechanical first-principle investigations of these alloys on the elemental distribution identify a family of B2 type of partially ordered configurations. We map out the elastic parameters in detail as a function of composition and temperature for disordered and partially ordered phases. A great sensitivity to the order-disorder transformation is revealed, especially for the Cr-rich system. Our results demonstrate that a proper control of the ordering level in these alloys can facilitate the optimal tuning of their mechanical performance while keeping the density almost unchanged. The study presented here further predicts that these alloys possess high specific stiffness, low thermal expansion, and large elastic softening resistance. It is demonstrated that the considered alloys have thermal and mechanical properties that compete with superalloys and other high temperature structural materials.

ACTA Vol. 199, 15 Oct. 2020, P63-72

4. Grain boundary segregation beyond the dilute limit: Separating the two contributions of site spectrality and solute interactions

區分溶質位置和溶質相互作用對稀溶液極限以上晶界偏聚的貢獻

Malik Wagih, Christopher A. Schuh?

C.A. Schuh:schuh@mit.edu

https://doi.org/10.1016/j.actamat.2020.08.022

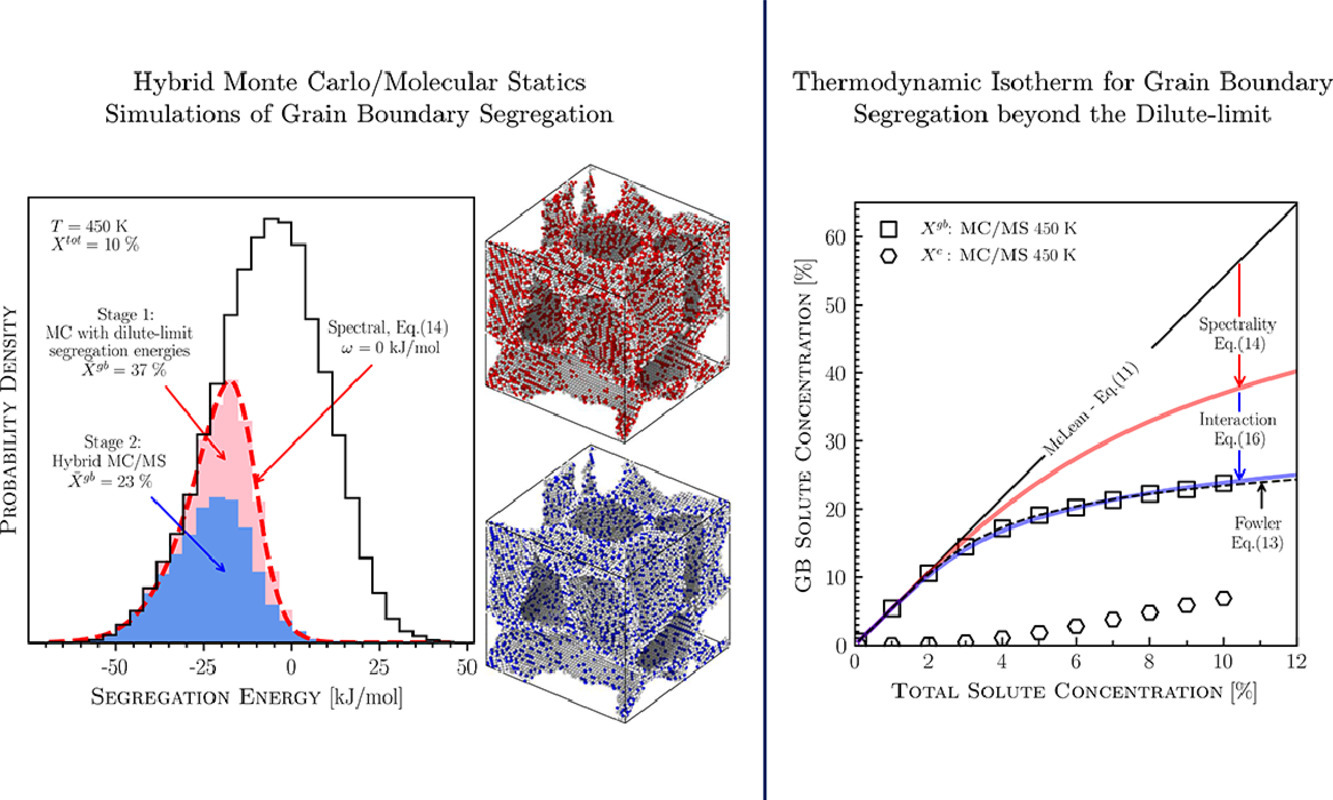

摘要

晶界處的元素偏聚對材料性能有顯著影響,對它的調控已經逐漸變成一種常見的材料設計理念。在超過過稀溶液濃度極限情況下,學界普遍認為晶界偏聚和材料的成分密切相關。通過對Al中Mg偏聚的蒙特卡洛/分子靜態混合模擬,我們把這種成分對偏聚的影響分成了兩個方面:(1)界面處的局部原子環境 (2)溶質元素之間的相互作用。通常,文獻中只討論了影響因素(2),在此我們指出,兩種因素對于定量理解二元合金中的晶界元素偏聚是同等重要的。最后,我們做出了關于晶界位置和溶質元素相互作用的熱力學偏聚等濃度圖。McLean或Fowler-Guwggenheim等經典圖譜通常只能在較為有限的溫度和成分范圍內對晶界偏聚進行描述,而我們作的這一圖譜在整個成分-溫度空間內都十分準確。

英文摘要

Solute segregation at grain boundaries (GBs) is known to have a profound impact on material properties, and as such is becoming routinely used as an element in alloy design. Beyond the dilute limit, the extent of solute GB segregation is known to be concentration dependent. Using hybrid Monte Carlo/Molecular Statics simulations of Mg segregation in Al, we decouple the two contributions to this composition dependence: (i) spectrality of atomic environments at the boundary and (ii) solute-solute interactions. Although only contribution (ii) is typically considered in the literature, we argue that both contributions are equally important to understand concentration dependence and correctly quantify GB solute segregation in a binary alloy. Finally, a thermodynamic segregation isotherm is outlined that accounts for both the spectrality of grain boundary sites and solute-solute interactions. Unlike classical isotherms like those of McLean or Fowler-Guggenheim, which can be successfully fitted to GB segregation data only over a limited range of composition and temperature, our proposed model is shown to be accurate across the composition-temperature space.

ACTA Vol. 199, 15 Oct. 2020, P73-84

5. Mechanism of ultrasound-induced microstructure modification in Al–Zr alloys

利用超聲熔煉對Al-Zr合金進行組織調控的機理研究

Jae-Gil Jung?, Young-Hee Cho, Sung-Dae Kim, Soo-Bae Kim, Sang-Hwa Lee, Kyung Song, Kwangjun Euh, Jung-Moo Lee

J.-G. Jung:jgjung@kims.re.kr

https://doi.org/10.1016/j.actamat.2020.08.025

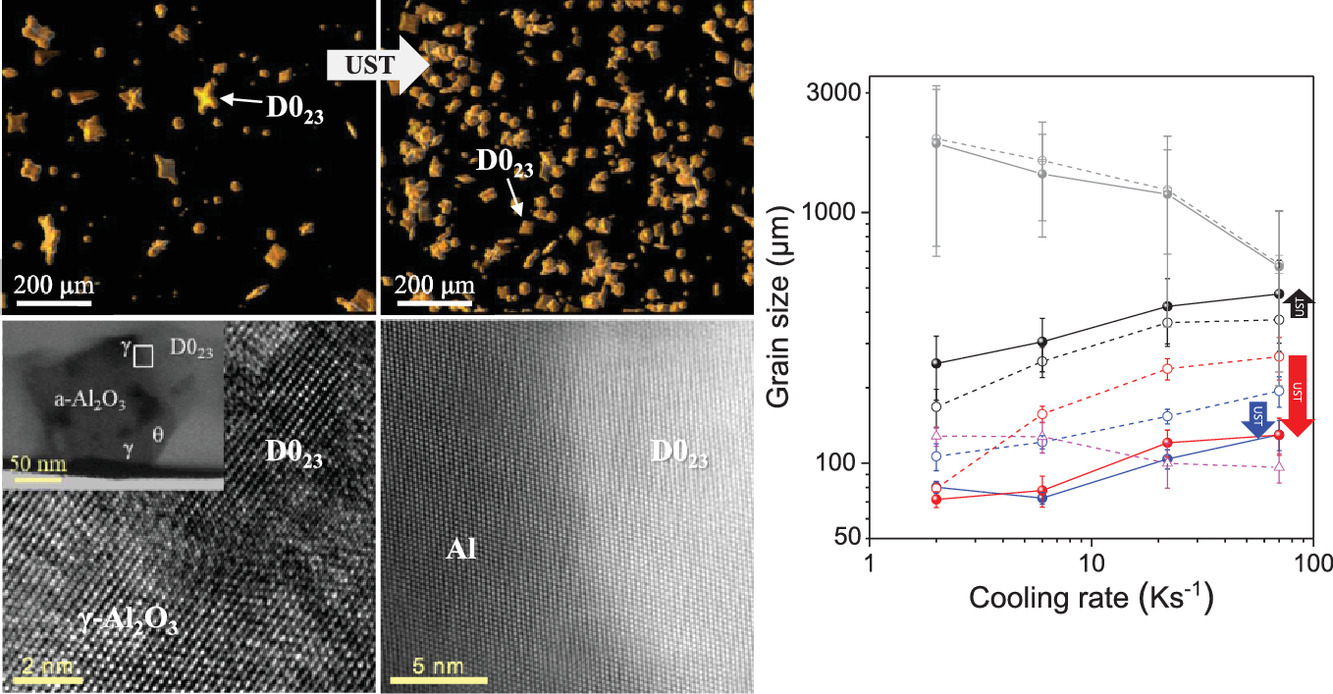

摘要

我們通過對純Al和幾種Al-Zr合金(Al–0.3Zr–0.1Ti, Al–0.5Zr, Al–0.5Zr–0.5Mg–0.9Si)在不同冷卻速率(0.2–70 K s−1)下進行凝固,研究了超聲熔煉(UST)對金屬間化合物粒子和α-Al的影響。研究發現,超聲熔煉會促進α-Al的形核,從而降低D023結構Al3Zr和 Al3(Zr,Ti) 粒子的尺寸,提高其體積分數和密度。高分辨率TEM表征表明,空位的浸潤效應和彌散分布的γ-Al2O3變質劑有助于細化初生金屬間化合物顆粒。隨著冷卻速率的增加,初生金屬間化合物粒子形成減少,導致Al-Zr合金的晶粒尺寸增大。在無鈦Al-Zr合金中,超聲熔煉細化了Al3Zr的尺寸,提高了Al3Zr的數密度,導致晶粒細化;而對于含鈦Al-Zr合金,超聲誘導晶粒細化只能在非常低的的冷卻速率下實現0.2 K s−1,這可能是由于超聲熔煉抑制了Ti的生長所產生副作用。快速凝固使組織中生成了大量L12-Al3Zr納米沉淀(~ 5nm),這一顯著的時效硬化不受超聲熔煉的影響。因此,本研究表明,在高冷卻速率下,UST可以降低時效硬化Al-Zr合金的晶粒粗化。

英文摘要

This work probes the effect of ultrasonic melt treatment (UST) on primary intermetallic particles and α-Al using pure Al and Al–Zr alloys (Al–0.3Zr–0.1Ti, Al–0.5Zr, Al–0.5Zr–0.5Mg–0.9Si) solidified at various cooling rates of 0.2–70 K s−1. The application of UST is shown to decrease the size and increase the number density and volume fraction of D023-structured primary Al3Zr and Al3(Zr,Ti) particles with a high nucleation potency for α-Al formation. High-resolution transmission electron microscopy analysis reveals that the cavitation-induced wetting and dispersion of γ-Al2O3 inoculant particles contribute to the refinement of primary intermetallic particles. The grain size of Al–Zr alloys increases with increasing cooling rate because of the concomitantly reduced formation of primary intermetallic inoculant particles. The UST-induced refinement of primary Al3Zr particles and the increased number density lead to grain refinement in Ti-free Al–Zr alloys. For the Ti-containing Al–Zr alloy, UST-induced grain refinement is achieved only at a very low cooling rate of 0.2 K s−1, possibly because of the side effects of UST on the growth-restricting influence of Ti. The fast cooling–induced solidification enables significant age-hardening by L12-Al3Zr nanoprecipitation (~5 nm) and is not affected by UST. Thus, this study shows that UST can be used to reduce the degree of grain coarsening of age-hardenable Al–Zr alloys at high cooling rates.

ACTA Vol. 199, 15 Oct. 2020, P107-115

6. Thermodynamic route for self-forming 1.5 nm V-Nb-Mo-Ta-W high-entropy alloy barrier layer: Roles of enthalpy and mixing entropy

V-Nb-Mo-Ta-W高熵合金中自發形成1.5nm阻隔層的熱力過程中焓和混合熵的作用

Yu-Ting Hsiao, Chi-Huan Tung, Su-Jien Lin, Jien-Wei Yeh, Shou-Yi Chang?

S.-Y. Chang:changsy@mx.nthu.edu.tw,臺灣國立清華大學

https://doi.org/10.1016/j.actamat.2020.08.029

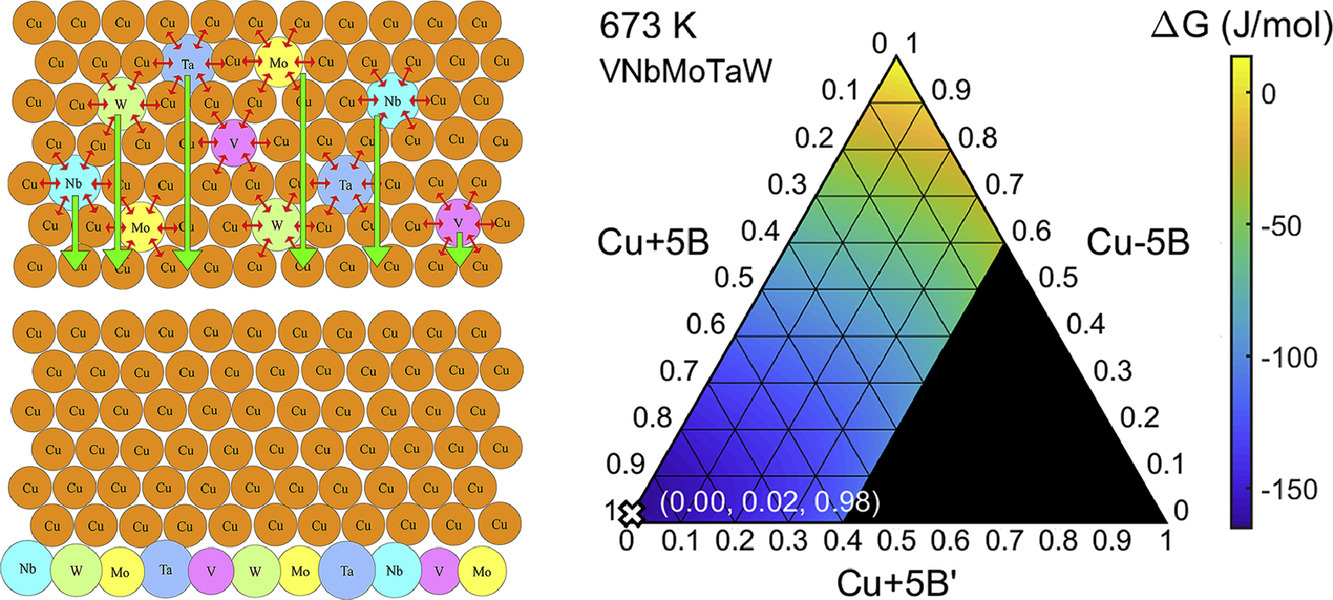

摘要

本研究報道了一種自發形成的V-Nb-Mo-Ta-W超薄高熵合金層的熱力學路徑,這種合金層有望成為一種具有廣闊實用前景的擴散壁壘。研究發現,在摻雜了1到5種金屬元素(V, Nb, Mo, Ta, W)共計1.2at.% 的銅合金薄膜中,這些元素會自發偏聚。在焓和混合熵的吉布斯自由能競爭下,5種合金元素在Cu/Si界面處形成了固溶合金層,而3種元素在晶界形成了金屬間化合物團簇。決定這些合金元素最終狀態的因素包括Cu的焓,合金元素和的焓,以及合金元素的混合焓。這種1.5 nm厚的自發形成五元合金層在700°C顯著阻礙了Cu和Si的相互擴散,且性能優于其他已實用化的阻隔材料。

英文摘要

This study reports a thermodynamic route for self-forming an ultrathin V-Nb-Mo-Ta-W high-entropy alloy layer for potential use as a promising diffusion barrier. In Cu alloy films minor-doped with 1.2 at.% of one-to-five metallic elements (V, Nb, Mo, Ta and W), the alloying elements spontaneously segregated. Under the competition of enthalpy and mixing entropy that determines the delta Gibbs free energy, one and, in particular, five alloying element(s) formed an alloy solution layer at the Cu/Si interface, whereas three alloying elements differently formed intermetallic compound clusters at the grain boundaries of Cu. Dominant factors for the final states of the alloying elements include the large positive enthalpy between Cu and the alloying elements, the negative enthalpy among the alloying elements, and the low-to-high mixing entropy among the alloying elements. The self-forming quinary alloy layer of only 1.5 nm thick provided excellent resistance to the interdiffusion of Cu and Si up to 700°C, better than practical and other newly developed barrier materials.

ACTA Vol. 199, 15 Oct. 2020, P116-128

7. A mean-field model of static recrystallization considering orientation spreads and their time-evolution

考慮取向傳播及其時間演化的靜態再結晶平均場模型

A. Després?, M. Greenwood, C.W. Sinclair

A. Després:arthur.despres@alumni.ubc.ca

https://doi.org/10.1016/j.actamat.2020.08.013

摘要

在本研究中,我們構建了一種平均場模型用于模擬晶體材料在靜態再結晶過程中的組織演化。模型考慮了一群單一晶粒/亞晶在均勻材料中的長大。計算晶粒長大速率所需的單個晶粒和材料整體的晶界性質均是基于材料的晶體學取向分布進行靜態估計得到。再結晶是不同晶粒相互競爭長大的結果。我們首先對采用的算法進行了闡述,隨后我們將平均場模型與二維頂點全場模型進行了比較,發現平均場模型能夠更準確地預測晶界性質隨時間的變化以及晶粒取向等再結晶動力參數。這一研究結果使我們能夠進一步探究晶粒取向對晶界性質、再結晶形成和再結晶動力學的影響。這一模型還能夠將實驗實測參數作為輸入,研究形變和再結晶之間的關系。

英文摘要

In this paper, we develop a mean-field model for simulating the microstructure evolution of crystalline materials during static recrystallization. The model considers a population of individual cells (i.e. grains and subgrains) growing in a homogeneous medium representing the average microstructure properties. The average boundary properties of the individual cells and of the medium, required to compute growth rates, are estimated statistically as a function of the microstructure topology and of the distribution of crystallographic orientations. Recrystallized grains arise from the competitive growth between cells. After a presentation of the algorithm, the model is compared to full-field simulations of recrystallization performed with a 2D Vertex model. It is shown that the mean-field model predicts accurately the evolution of boundary properties with time, as well as several recrystallization parameters including kinetics and grain orientations. The results allow one to investigate the role of orientation spreads on the determination of boundary properties, the formation of recrystallized grains and recrystallization kinetics. The model can be used with experimentally obtained inputs to investigate the relationship between deformation and recrystallization microstructures.

ACTA Vol. 199, 15 Oct. 2020, P129-140

8. The influence of microstructural condition on the phase transformations in Ti-24Nb (at.%)

組織狀態對Ti-24Nb (at.%)合金相變的影響

E.M. Hildyard, L.D. Connor, L.R. Owen, D. Rugg, N. Martin, H.J. Stone, N.G. Jones?

N.G. Jones:ngj22@cam.ac.uk

https://doi.org/10.1016/j.actamat.2020.08.004

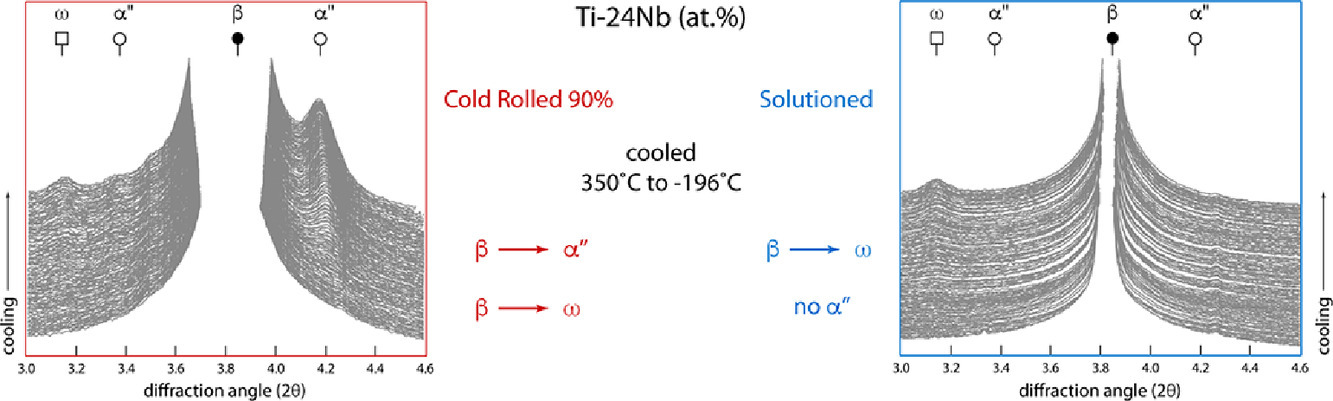

摘要

Ti-Nb合金在較廣的溫度范圍內具備超彈性和形狀記憶效應,這使得它們很有工業應用潛力。然而,不同文獻對于給定成分合金相變行為的報導具有顯著區別,且目前為止其原因尚無法解釋,這極大地限制了Ti-Nb合金的應用。為了研究這些差異的原因,我們選取了兩種具有不同微觀組織的Ti-24Nb合金,其中一種為冷軋態(CR),另一種為固溶態(ST),通過在三步熱循環處理結合同步輻射對其相變行為進行了研究。當材料從350?C冷卻到-196?C時,CR合金發生了β-α?和β-ω兩種相變,而ST合金只發生了β-ω相變。這一結果表明Ti-Nb合金的相變行為,尤其是對β-α?相變,顯著受到材料預處理的影響,且關于α?和ω相的互斥理論需要優化改進。我們發現材料的部分特征與單一熱驅動的馬氏體形成機制不符,并對涵蓋了其他因素的機制描述進行了討論。

英文摘要

Ti-Nb based alloys exhibit superelastic and shape memory properties over a wide range of temperatures, making them attractive for industrial applications. However, within the literature there are significant variations in the reported transformation behaviour for a given composition that remain unexplained. These variations are problematic to engineering design and limit the industrial uptake of these alloys. To investigate the source of these discrepancies, the transformation behaviour of Ti-24Nb (at.%) in two significantly different microstructural conditions, following cold rolling (CR) and following a subsequent solution heat treatment (ST), has been studied using in situ synchrotron diffraction data whilst undergoing a three step thermal cycle. When cooling from 350 to -196?C, the CR condition material underwent both the β to α? and β to ω transformations, whilst only the β to ω transformation was observed in the ST condition material. These results show that the transformation behaviour of Ti-Nb alloys, in particular the β to α? transformation, is significantly influenced by prior processing and that theories of mutual exclusivity between α? and ω phase formation need revisiting. In addition, several features within the datasets were inconsistent with a solely thermally driven martensite formation mechanism and an alternative description that includes other factors is discussed.

ACTA Vol. 199, 15 Oct. 2020, P141-154

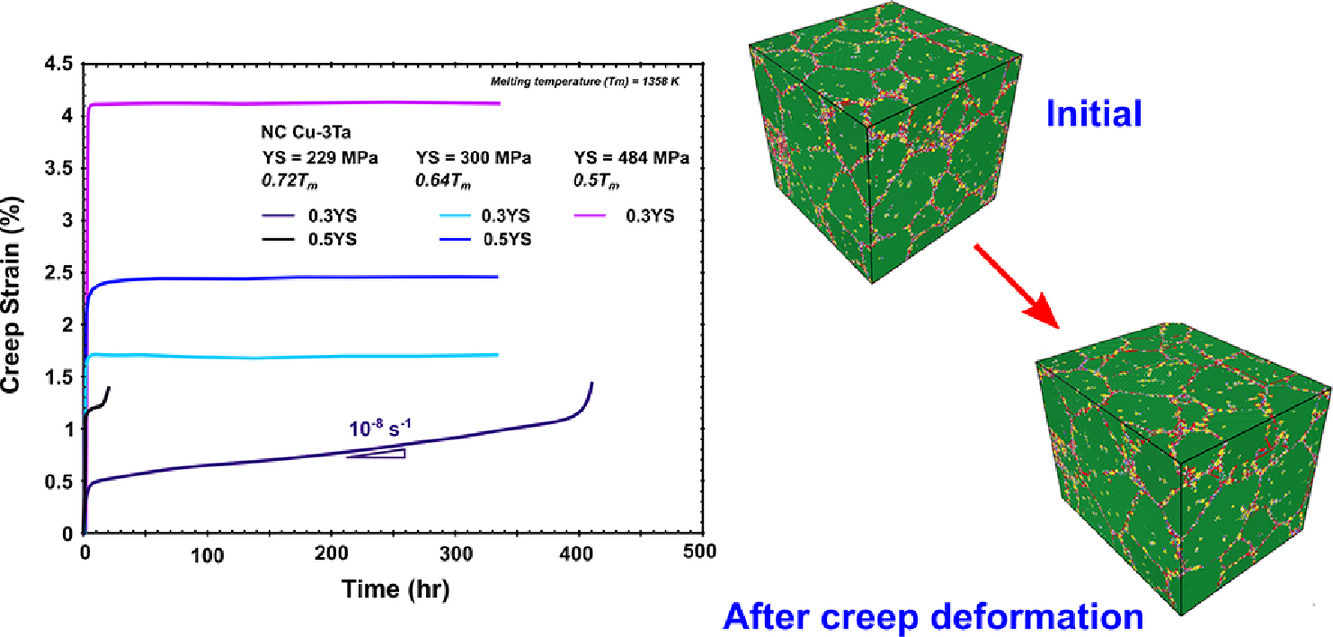

9. An experimental and modeling investigation of tensile creep resistance of a stable nanocrystalline alloy

一種穩定納米合金的抗拉伸蠕變實驗和模擬研究

C. Kale, S. Srinivasan, B.C. Hornbuckle, R.K. Koju, K. Darling, Y. Mishin?, K.N. Solanki ?

Y. Mishin:ymishin@gmu.edu

K.N. Solanki:kiran.solanki@asu.edu

https://doi.org/10.1016/j.actamat.2020.08.020

摘要

納米晶材料與粗晶材料相比,在室溫下往往具有更高的強度,更好的韌性和更好的耐磨性。但是,由于納米晶的吉布斯自由能較高,因此在高溫下很不穩定。實驗上,常在相對較低的溫度就已經觀測到納米晶的顯著長大,這在很大程度上限制了納米晶材料的實際應用。在本文中,我們提出了一種新的設計思路,大幅提高了納米Cu-Ta合金在高溫(0.64熔點)下的拉伸蠕變性能。這一設計思路通過固溶使得材料在晶界處和晶粒內部產生溶質元素的納米團簇分布。我們發現加入Ta元素形成納米團簇能夠阻礙高溫下的晶界遷移和位錯運動。這使得材料表現出反常的拉伸蠕變行為,例如,不會出現在絕大多數材料中都有的穩態蠕變。這種設計策略能夠幫助我們較為容易地大規模生產抗蠕變納米晶部件,并可以應用于其他多組分系統中,如鎳基合金。

英文摘要

Nanocrystalline (NC) materials possess excellent room temperature properties, such as high strength, wear resistance, and toughness as compared to their coarse-grained counterparts. However, due to the excess free energy, NC microstructures are unstable at higher temperatures. Significant grain growth is observed already at moderately low temperatures, limiting the broader applicability of NC materials. Here, we present a design approach that leads to a significant improvement in the high temperature tensile creep resistance (up to 0.64 of the melting temperature) of a NC Cu-Ta alloy. The design approach involves alloying of pure elements to create a distribution of nanometer sized solute clusters within the grains and along the grain boundaries. We demonstrate that the addition of Ta nanoclusters inhibits the migration of grain boundaries at high temperatures and reduces the dislocation motion. This leads to a highly unusual tensile creep behavior, including the absence of any appreciable steady-state creep deformation normally observed in almost all materials. This design strategy can be readily scaled-up for bulk manufacturing of creep-resistant NC parts and transferred to other multicomponent systems such as Ni-based alloys.

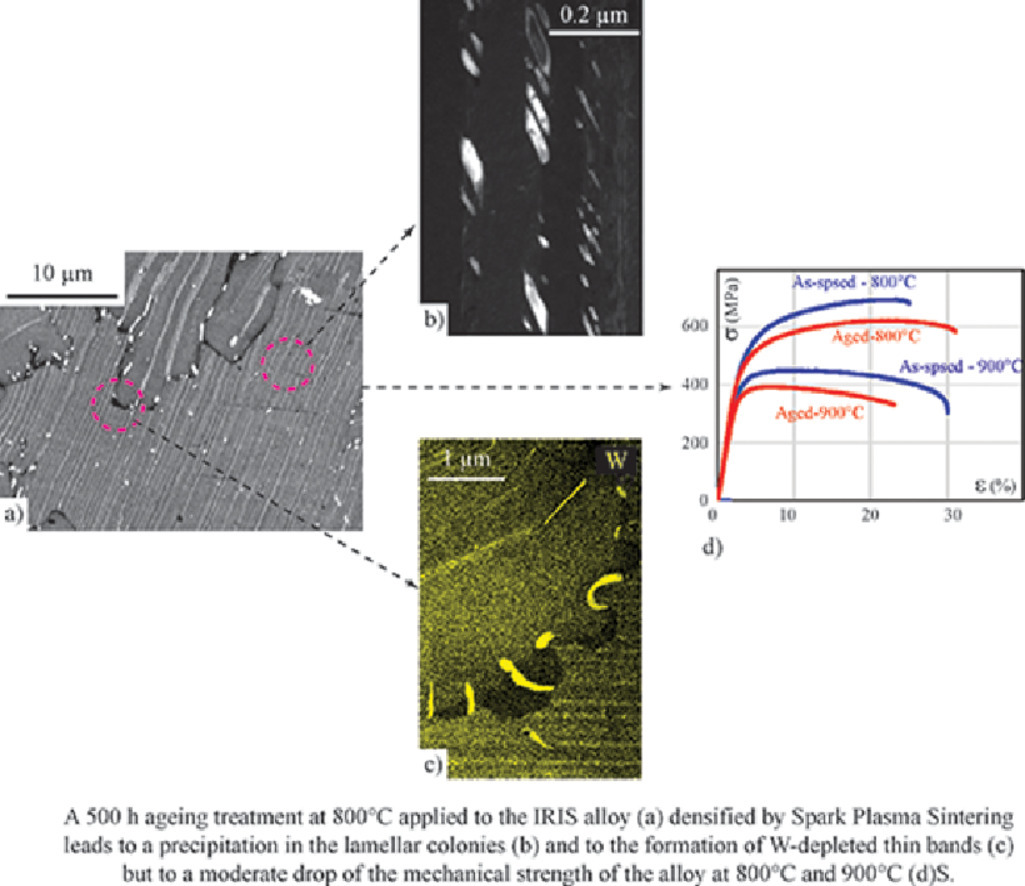

ACTA Vol. 199, 15 Oct. 2020, P169-180

10. Effect of ageing on the properties of the W-containing IRIS-TiAl alloy

時效處理對含鎢IRIS-TiAl合金性能的影響

Alain Couret?, David Reyes, Marc Thomas, Nicolas Ratel-Ramond, Christophe Deshayes, Jean-Philippe Monchoux

A. Couret:alain.couret@cemes.fr

https://doi.org/10.1016/j.actamat.2020.07.061

摘要

我們研究了800 °C回火對IRIS合金(Ti49.9Al48W2B0.1)性能的影響。經等離子燒結致密化后的合金初始組織主要為γ晶粒圍繞的層狀組織。我們對時效處理后合金的強度和蠕變性能進行了相應力學實驗測量;并用掃描、透射電子顯微鏡和X射線衍射對材料的組織變化進行了表征。結果表明,組織演變主要表現為層片狀區域的收縮和β0相的析出,同時伴隨鎢的偏析和α2層寬度的減小。由于鎢的低擴散率,使得這些組織變化相對有限。與之形成對比的是,在室溫和高溫下時效,可以對材料的機械性能產生不可忽視的影響。我們從微觀組織的演變和不同溫度下的變形機理等方面對實驗結果進行了解釋和討論。

英文摘要

The effects of ageing at 800 °C on the properties of the IRIS alloy (Ti49.9Al48W2B0.1) are studied. The initial microstructure of this alloy densified by Spark Plasma Sintering (SPS) is mainly composed of lamellar colonies which are surrounded by γ grains. The evolutions of the alloy strength and creep resistance resulting from this ageing treatment are measured by the related mechanical tests. The microstructural changes are investigated by scanning and transmission electron microscopies and by X-ray diffraction.The main structural evolutions consist in a shrinkage of the lamellar areas and in a precipitation of β0 phase, which is accompanied by a moderate segregation of tungsten and a decrease of the α2 lamellar width. However, these evolutions are relatively limited and the microstructural stability is found to result mainly from the low diffusivity of tungsten. Conversely, a moderate effect of this ageing treatment on mechanical properties, at room and high temperatures, is measured. Such experimental results are interpreted and discussed in terms of the microstructural evolutions and of the deformation mechanisms which are activated at different temperatures under various solicitations.

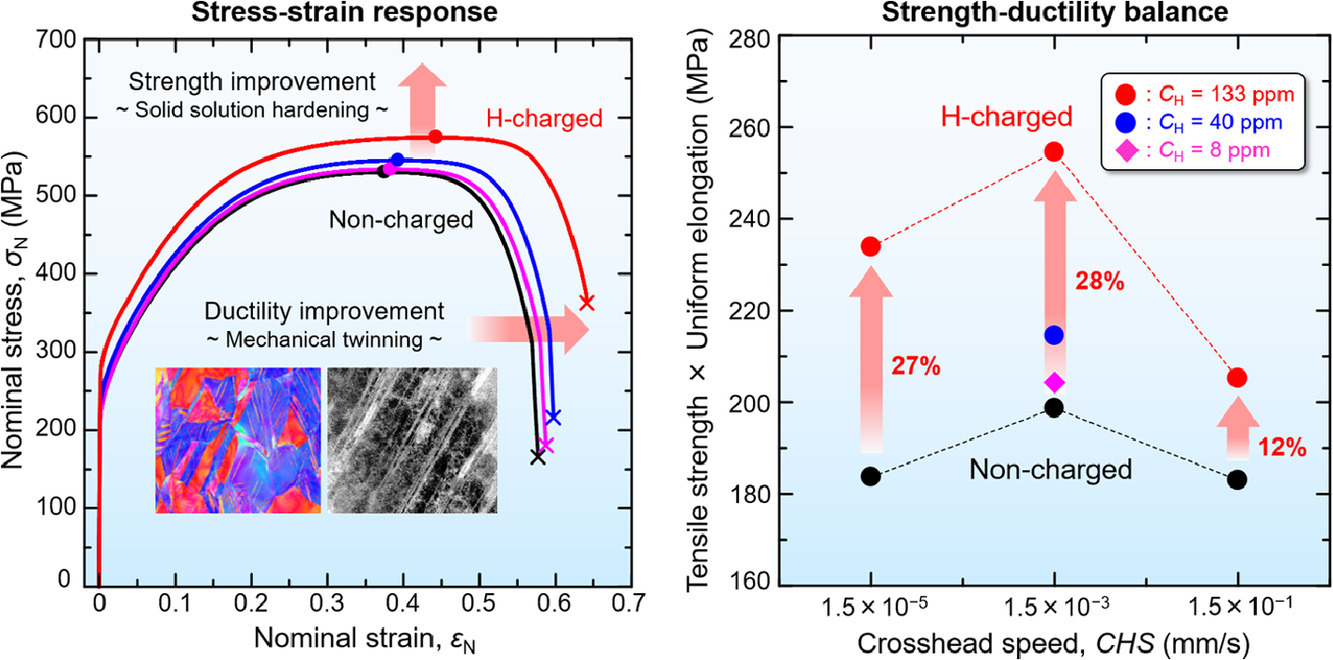

ACTA Vol. 199, 15 Oct. 2020, P181-192

11. Hydrogen, as an alloying element, enables a greater strength-ductility balance in an Fe-Cr-Ni-based, stable austenitic stainless steel

氫作為一種合金元素使鐵鉻鎳基奧氏體不銹鋼具有更好的強度-延展性平衡

Yuhei Ogawa?, Hyuga Hosoi, Kaneaki Tsuzaki, Timothée Redarce, Osamu Takakuwa, Hisao Matsunaga

Y. Ogawa:ogawa.yuhei.778@m.kyushu-u.ac.jp

https://doi.org/10.1016/j.actamat.2020.08.024

摘要

我們發現,在商業化Fe-24Cr-19Ni合金中預充~7000 at.ppm的H溶質可以在不同變形速率拉伸試驗中對材料的強度和延展性產生獨特影響。其中,氫對材料強度的影響表現為屈服強度、流動應力和拉伸強度的提高;而對延展性的影響表現為均勻延伸率和斷裂應變的增加,并且這兩者的提高隨著氫濃度的增加而更加顯著。我們把拉伸強度與均勻伸長率之間的乘積作為強韌性的綜合指標,在特定的中間應變速率下,給出了充氫對材料性能的最大優化。我們認為,屈服/流動應力的增加是由于固溶強化,而延展性的增強主要是因為機械孿晶。應力松弛實驗間接揭示了動態氫-位錯的相互作用對材料性能的關鍵影響,支持了我們的結論。

英文摘要

After pre-charging at the gaseous phase with a concentration of ~7,000 at. ppm, solute hydrogen was discovered to have an abnormal effect on both the strength and ductility enhancement of a commercially-available, Fe-24Cr-19Ni-based, stable austenitic stainless steel that had been subjected to tensile testing at various strain-rates. Specifically, the impact of hydrogen on material strength was accompanied by amplified yield and flow stresses, as well as tensile strength, while the improvement in ductility featured extended uniform elongation and strain-to-fracture, both of which became more pronounced as hydrogen concentration intensified. The product between tensile strength and uniform elongation served as indicators of the strength-ductility balance, at which hydrogen maximally optimized the indicator at the particular intermediate strain-rate. The yield/flow stress augmentations were interpreted in terms of solid-solution strengthening, whereas the enhanced ductility was primarily ascribed to the facilitation of mechanical twinning, whereby dynamic hydrogen-dislocation interaction exerted a critical influence as was indirectly revealed by supplemental stress-relaxation experiments.

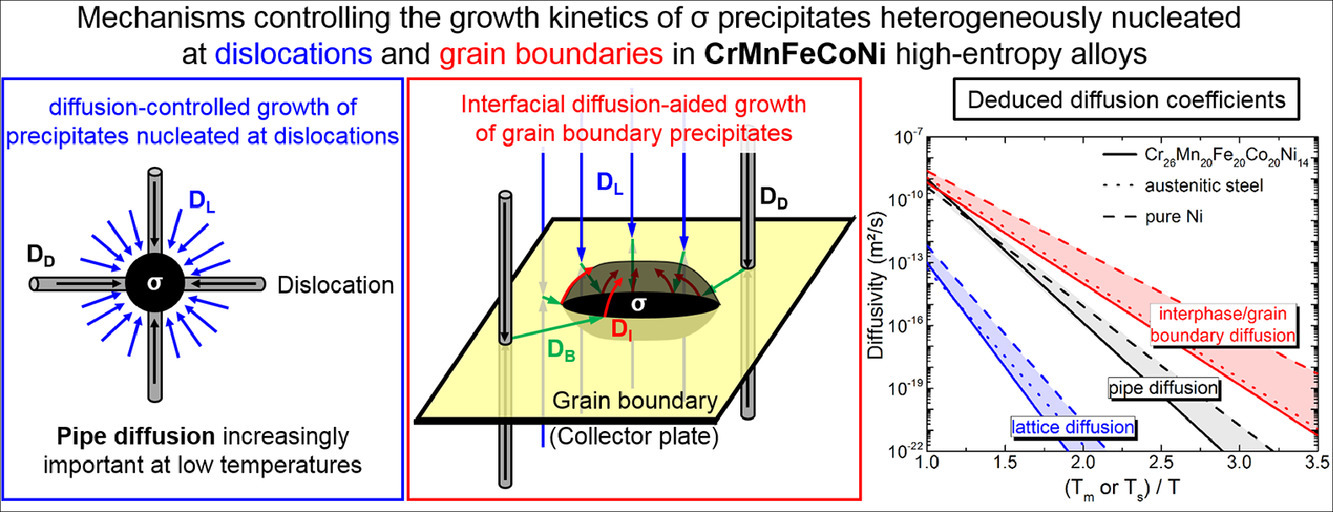

ACTA Vol. 199, 15 Oct. 2020, P193-208

12. Growth kinetics of σ-phase precipitates and underlying diffusion processes in CrMnFeCoNi high-entropy alloys

CrMnFeCoNi高熵合金中σ相析出物的長大動力學及擴散過程

Guillaume Laplanche?

Guillaume Laplanche:guillaume.laplanche@rub.de

https://doi.org/10.1016/j.actamat.2020.08.023

摘要

我們研究了高熵合金中控制σ析出長大的關鍵機制和元素擴散過程。我們采用FCC單相Cr26Mn20Fe20Co20Ni14 合金作為研究對象,通過在600 °C-1000 °C進行0.1 h到1000 h的等溫熱處理使材料中析出σ相。我們對晶界處析出的σ相和晶粒內析出的σ相分別研究,發現晶粒內的σ析出是由于Cr向Mn、Fe、Co的擴散和Ni向Mn、Fe、Co的遠離導致的,而晶界σ析出的長大速率則與界面擴散控制的盤狀析出長大機制預測吻合。通過實驗獲得的動力學數據,我們推導得到了晶格擴散系數和缺陷擴散系數。在800 °C以上,析出長大主要受Cr在FCC基體中的擴散控制,擴散系數DL = 9.8×10-4exp[(-300 kJ/mol)/(RT)] m2/s。較低溫度下,析出動力學因位錯處的快速擴散而增加,擴散系數DD = 5.0×10-3exp[(-205 kJ/mol)/(RT)] m2/s。沿σ/FCC界面的Cr擴散速率可以通過晶界析出的粗化動力學推導并用阿倫尼烏斯公式表示,DI = 0.5×10-4exp[(-145 kJ/mol)/(RT)] m2/s。這一數值與合金中的晶界擴散系數大體相當。

英文摘要

Key mechanisms and elementary diffusion processes that control the growth kinetics of σ precipitates in high-entropy alloys were investigated in the present study. For this purpose, an off-equiatomic Cr26Mn20Fe20Co20Ni14 alloy with an initially single-phase FCC structure was subjected to isothermal heat treatments, which are known to promote the formation of σ phase, i.e., aging between 600 °C and 1000 °C for times ranging from 0.1 h to 1000 h. The growth kinetics of σ precipitates at grain boundaries of the FCC matrix and those located within the interior of the grains were analyzed separately. The latter precipitates are found to grow through direct substitutional diffusion of Cr-solutes towards and Mn, Fe, Co, and Ni away from them and the growth rate of the allotriomorphs can be rationalized by the collector plate mechanism of interfacial diffusion-aided growth. From the growth-kinetics data obtained in the present study, lattice interdiffusion coefficients as well as diffusivities along crystalline defects were obtained. Above 800 °C, the growth kinetics are dominated by lattice interdiffusion of Cr in the FCC matrix described by DL = 9.8×10-4exp[(-300 kJ/mol)/(RT)] m2/s. At lower temperatures, the growth kinetics are enhanced by fast interdiffusion along dislocation pipes, which temperature dependence is given by DD = 5.0×10-3exp[(-205 kJ/mol)/(RT)] m2/s. The Cr-diffusivity along σ/FCC interphase boundaries deduced from the thickening kinetics of grain boundary precipitates can be represented by the Arrhenius relationship DI = 0.5×10-4exp[(-145 kJ/mol)/(RT)] m2/s, which is similar to that found for grain boundary interdiffusion in metals and alloys.

ACTA Vol. 199, 15 Oct. 2020, P209-224

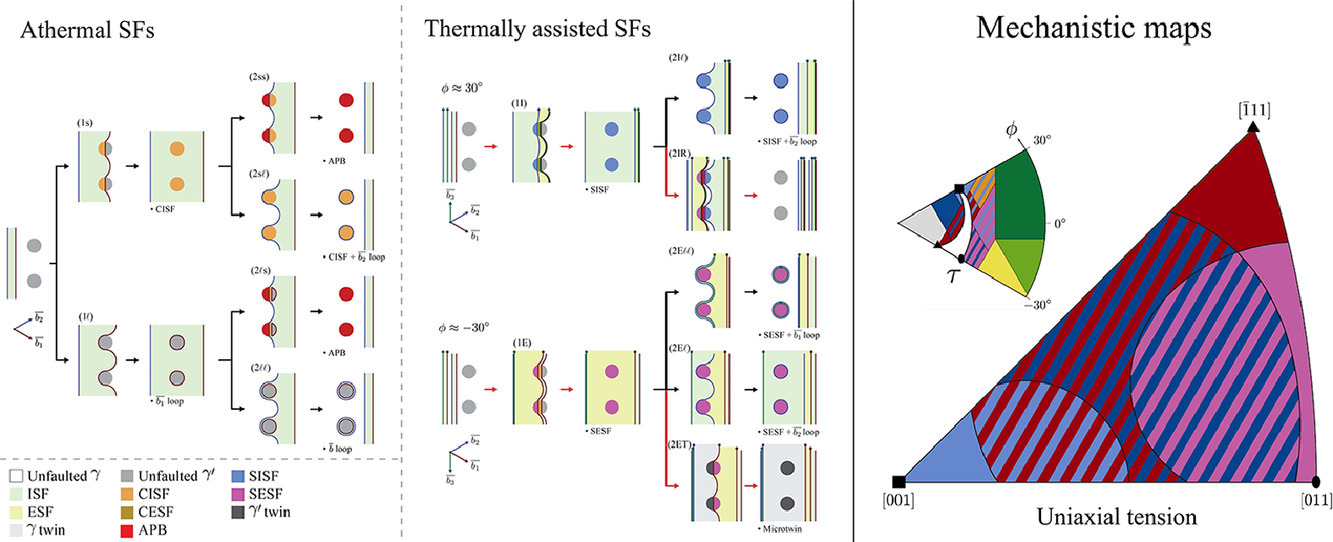

13. Stress orientation dependence for the propagation of stacking faults and superlattice stacking faults in nickel-based superalloys

鎳基高溫合金中應力取向對層錯和超晶格層錯擴展的影響

F.D. León-Cázares?, F. Monni, C.M.F. Rae

F.D. León-Cázares:fdl22@cam.ac.uk

https://doi.org/10.1016/j.actamat.2020.08.032

摘要

超晶格層錯的擴展是在影響鎳基高溫合金中溫蠕變性能的主要因素。根據位錯的分布以及位錯與析出的相互作用,這些平面缺陷可能在各種位置出現。盡管文獻中已經對這些層錯進行了大量表征,但是尚未有系統理論用于解釋這些層錯的配置情況。我們通過拉伸蠕變實驗結合TEM、SEM和EBSD對多晶中的層錯類型進行了定量研究。我們觀測到了一種由析出層錯和基體層錯共同組成的新型缺陷結構,并提出了其形成機制。結合文獻中的一些單晶數據,我們把實驗結果納入了已有的穩定預測框架中,以衡量取向對這些層錯的影響。我們首先建立了一系列不同位錯構型在立方和球形析出條件下發生層錯擴展的一維力學平衡分析模型,隨后將該模型應用到了6種超晶格和孿晶結構。模型提供了用于解釋了應力、取向和微觀結構的全新物理圖像,這些預測結果與實驗能夠很好地定性吻合。

英文摘要

Superlattice stacking fault propagation dominates the creep deformation behaviour of nickel-based superalloys at intermediate temperatures. These planar defects may appear under many different configurations depending on the dislocation arrangements and their interactions with the precipitates. Whilst these have been spotted and described before, no systematic way to explain their configurations has been provided. The current study quantifies the types of faults in multiple grains within a tensile crept polycrystalline alloy via a combination of scanning transmission electron microscopy and electron backscatter diffraction. A new defect consisting of a superlattice intrinsic stacking fault in the precipitates and an extrinsic stacking fault in the matrix is observed and a mechanism for its formation is proposed. In combination with data from the literature on single crystals, the results are incorporated into a robust framework to discern the orientation dependencies of these faults. A comprehensive analytical model based on a series of one-dimensional force balances on different dislocation configurations is developed first for the case of athermal stacking fault propagation for the cases of cuboidal and spherical precipitates. The model is then extended to include six configurations of superlattice faults and microtwinning. This results in novel mechanistic maps that account for stress, orientation and microstructure, with excellent qualitative agreement with experiments.

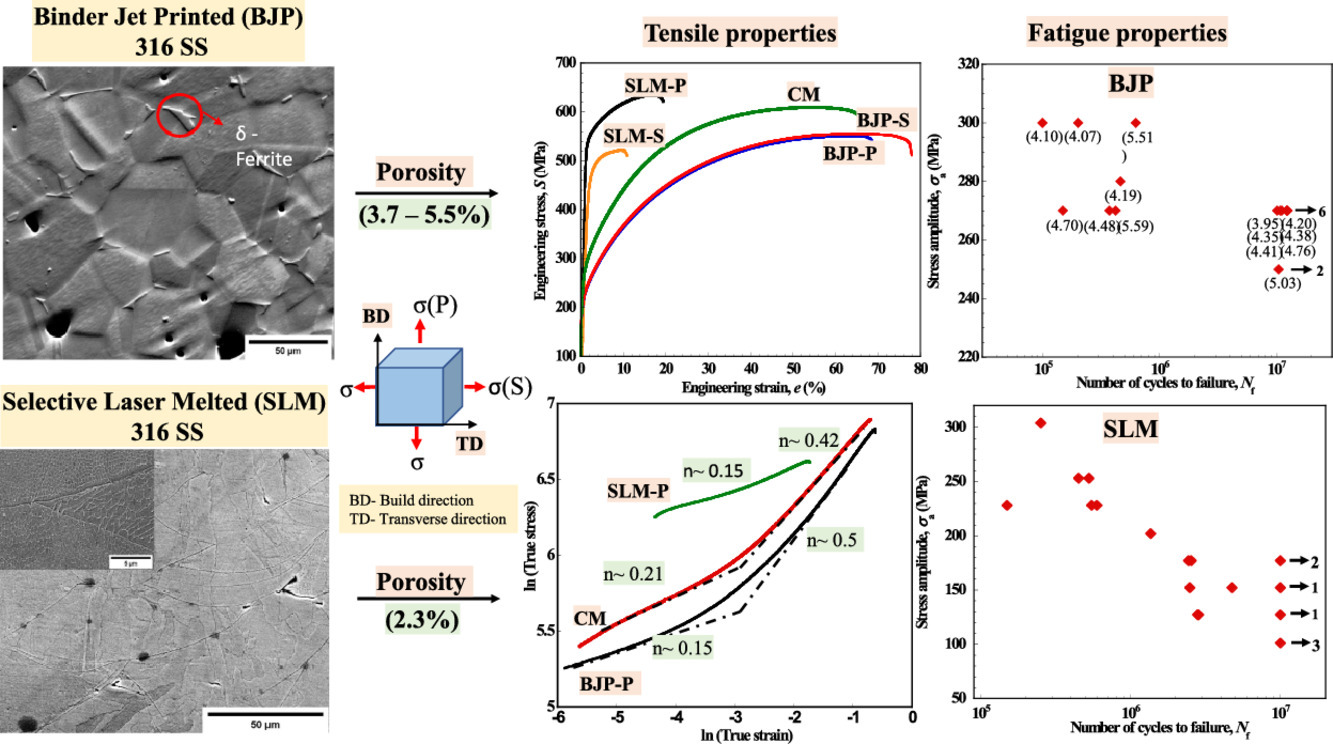

ACTA Vol. 199, 15 Oct. 2020, P225-239

14. Fatigue strength of additively manufactured 316L austenitic stainless steel

增材制造316L奧氏體不銹鋼的疲勞強度

Punit Kumar, R. Jayaraj, J. Suryawanshi, U.R. Satwik, J. McKinnell, U. Ramamurty?

U. Ramamurty:uram@ntu.edu.sg

https://doi.org/10.1016/j.actamat.2020.08.033

摘要

我們研究了使用粘結噴印方式(BJP)和選區激光熔化(SLM)兩種方式制備的316L不銹鋼的組織和性能,并將其與傳統方式(CM)制備的材料進行了比較,其中著重比較了它們的無缺口疲勞性能。結果表明,盡管BJP材料中含有大量孔洞,但是其加工硬化行為、韌性和疲勞性能都與CM材料十分接近。相比之下,SLM材料則強度更高(尤其是屈服強度),并且盡管孔洞比BJP樣品小得多,但韌性卻明顯更差。我們基于這兩種材料不同的加工環境導致的組織差異對這些實驗結果進行了合理解釋。在準靜態和循環載荷作用下,BJP合金塑性變形早期階段普遍存在的平面滑移機制以及其他微觀結構因素導致了在孔洞形核的小裂紋的中止,因此孔隙率對BJP合金的延展性和疲勞強度均無不利影響。而在SLM合金中,一方面胞狀組織可以顯著提高屈服強度;另一方面胞狀組織太細,而柱狀晶晶粒較大且取向差較小,因此無法引起裂紋轉向或中止。以上的實驗結果對具有良好機械性能的增材制造合金設計具有重要的指導意義。

英文摘要

The microstructures and mechanical properties of the 316L austenitic stainless steel fabricated using binder jet printing (BJP) and selective laser melting (SLM) were investigated and compared with those of the conventionally manufactured (CM) alloy, with particular emphasis on the unnotched fatigue resistance. Results show that the work hardening behavior, ductility, and fatigue strength (σf) of the BJP specimens, which contain significant amounts of pores, are surprisingly comparable to those of the CM alloy. In contrast, the SLM specimens are considerably stronger, especially in terms of the yield strength, less ductile, and far inferior in terms of σf although the porosity in them is relatively smaller as compared to the BJP specimens. These results are rationalized by recourse to the distinct microstructures in the two additively manufactured alloys, which stem from the different processing conditions experienced by them. The planar slip regime that prevails in the early stages of plastic deformation of the BJP alloys and a combination of other microstructural factors lead to the arrest of small cracks that nucleate at the corners of the pores, both under quasi-static and cyclic loads; as a result, neither ductility nor fatigue strength are adversely affected by the porosity in the BJP alloys. In the SLM alloy, the cellular structure, which enhances the yield strength considerably, is too fine whereas the columnar grains are minimally misoriented and coarse enough to induce any crack deflection or arrest. Implications of these results in terms of possible directions for designing AM alloys with high mechanical performance are discussed.

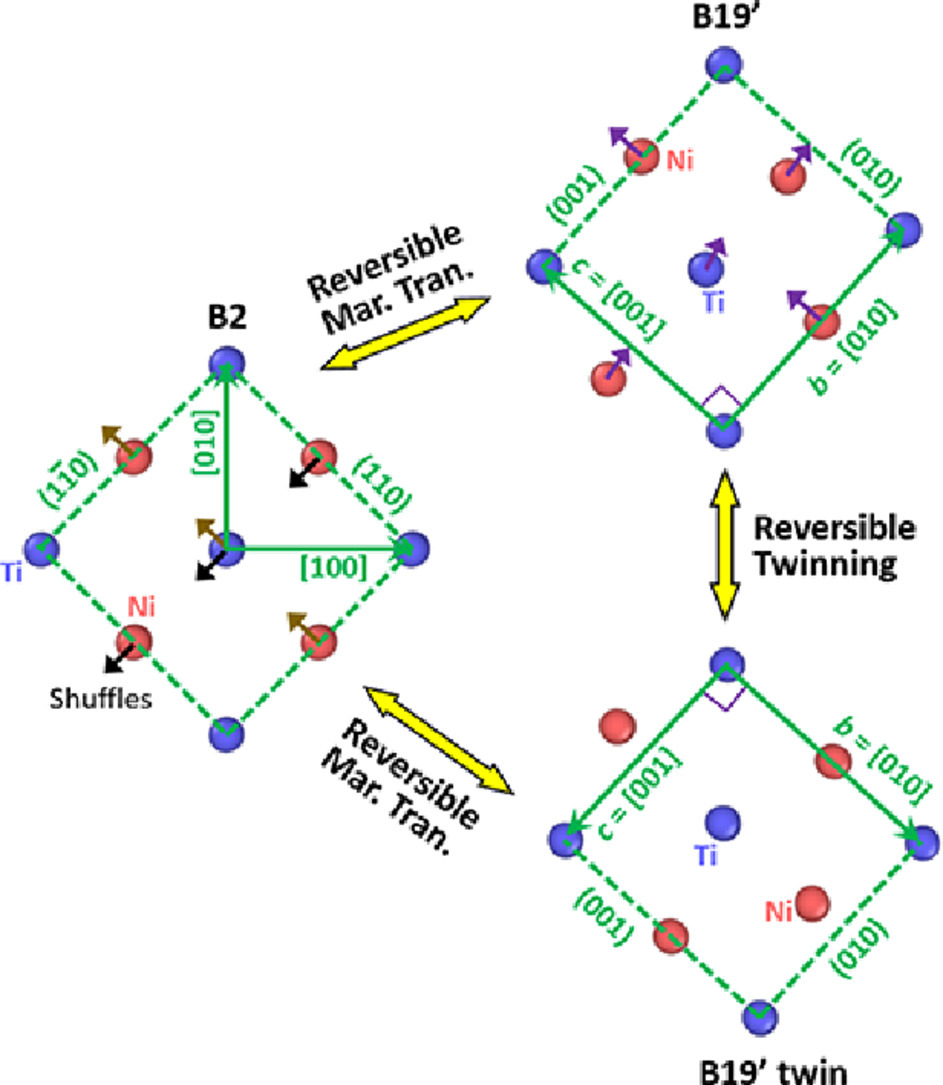

ACTA Vol. 199, 15 Oct. 2020, P240-252

15. Structural origin of reversible martensitic transformation and reversible twinning in NiTi shape memory alloy

鎳鈦形狀記憶合金可逆馬氏體相變和可逆孿晶在組織層面的起因

Bin Li?, Yidi Shen, Qi An

B. Li:binl@unr.edu

https://doi.org/10.1016/j.actamat.2020.08.039

摘要

在過去的幾十年中,關于NiTi形狀記憶合金中BCC奧氏體(B2)到單斜馬氏體(B19′)相變和馬氏體孿晶的機制取得了長足的進展。但目前為止,原子層面關于晶格關聯的研究卻鮮有報導,這使得我們難以全面而完整地理解馬氏體相變和孿晶的機理。因此,我們對B2 → B19′相變和該過程中發生的孿晶進行了原子尺度模擬,并且著重關注了相變和孿晶中的晶格關聯。模擬結果表明,當馬氏體在奧氏體中形核時,馬氏體會自發地與奧氏體形成孿晶關系。即,我們成功模擬了這種自適應過程。隨后組織發生合并,一些馬氏體晶粒長大,而鄰近晶粒消失,這一過程中界面是彈性的,其遷移可逆。最終,孿晶馬氏體形成。在B2→B19′轉變過程中,B19′單斜結構可被視為一種形變了的密排六方(HCP)結構。在這一視角下,NiTi合金中的馬氏體相變本質上類似于BCC↔HCP相變,只是其中發生了可逆的原子震蕩;同樣地,孿晶過程本質上也類似于HCP金屬中的{101-2}孿晶。另一個重要發現是,B19′馬氏體表現出一種非常特殊的雙晶結構:單斜晶胞中較弱的Ti-Ti鍵合使得晶胞容易發生二次取向。因此,兩個不同取向的晶胞可以共存在同一馬氏體晶粒中而使馬氏體失去了長周期結構,這為體系在適應應變時提供了額外的自由度。這些結果很好地解釋了B19 '馬氏體對拉伸的極強適應性及其變形可逆的原因。

英文摘要

Much progress has been made over the past few decades in resolving the mechanism for the transformation from ordered body-centered-cubic (B2) austenite to monoclinic martensite (B19′) in NiTi shape memory alloy, as well as the twinning mechanisms in martensite. However, so far no lattice correspondence analyses on the atomic scale have been conducted, as a result, these mechanisms have not been completely understood in terms of the pathways for reversible phase transition and reversible twinning in martensite. In this work, atomistic simulations were performed to investigate how B2 austenite transforms to B19′ martensite and how twins are formed during phase transformation. In particular, lattice correspondence in the structural evolutions was carefully analyzed to reveal the martensitic transformation mechanism and twinning mechanism with much better clarity. The simulation results show that, when martensite grains were nucleated in austenite, they already formed a twin relationship as a natural result of the crystal structure. Thus, self-accommodation is achieved naturally. Coalescence occurred subsequently and some martensite grains grew at the expense of their neighbors, indicating that the interfaces are elastically mobile and their migration is reversible. Eventually twinned martensite variants were created. It is shown that, in the B2 → B19′ transformation, the B19′ monoclinic structure can be treated as a distorted hexagonal close-packed (HCP) structure. With this treatment, it is demonstrated that the martensitic transformation is essentially similar to BCC ↔ HCP transformation which only involves atomic shuffles and is reversible, and twinning in martensite is essentially similar to {101-2} twinning in HCP metals which only involves atomic shuffles and is reversible as well. Another significant discovery is that the B19′ martensite exhibits a very special dual-lattice structure: the relatively weak Ti-Ti bonding of the monoclinic unit cell permits easy reorientation of lattice units. As a result, two differently oriented lattice units co-exist in the same martensite grain which loses long range periodicity, providing an extra degree of freedom for accommodating external and internal strains. These results explain well why B19′ martensite is extremely adaptive to straining and why deformation is reversible.

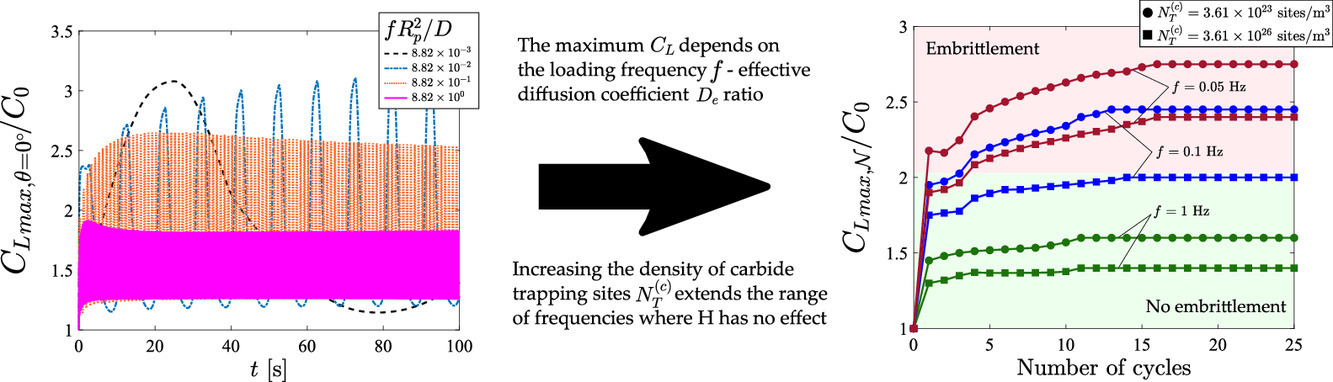

ACTA Vol. 199, 15 Oct. 2020, P253-263

16. Analysis of the influence of microstructural traps on hydrogen assisted fatigue

組織中的氫陷阱對氫致疲勞斷裂的影響分析

Rebeca Fernández-Sousa, Covadonga Betegón, Emilio Martínez-Pañeda?

E. Martínez-Pañeda:e.martinez-paneda@imperial.ac.uk

https://doi.org/10.1016/j.actamat.2020.08.030

摘要

我們研究了循環載荷下組織中的氫陷阱對氫擴散和氫脆的影響。我們建立了一個能涵蓋多種氫陷阱的有限元模型,并用它解釋了裂紋尖端形貌和氫濃度隨載荷頻率、結合能和陷阱密度的變化關系。結果表明,晶格中的最大氫濃度對載荷頻率和有效擴散系數的比值十分敏感。在預充氫的樣品(封閉系統)和暴露在氫源下的樣品(開放系統)中都觀測到了這一結果。我們設計了實驗確定了惰性環境下的氫致脆化臨界濃度。隨后,我們定量研究和討論了高陷阱密度材料對循環載荷過程中對氫脆的緩和作用。結果表明,與靜態條件下不同,增加陷阱密度是一種可行且可同時應用于封閉和開放系統的抗氫致疲勞合金設計策略。

英文摘要

We investigate the influence of microstructural traps on hydrogen diffusion and embrittlement in the presence of cyclic loads. A mechanistic, multi-trap model for hydrogen transport is developed, implemented into a finite element framework, and used to capture the variation of crack tip lattice and trapped hydrogen concentrations as a function of the loading frequency, the trap binding energies and the trap densities. We show that the maximum value attained by the lattice hydrogen concentration during the cyclic analysis exhibits a notable sensitivity to the ratio between the loading frequency and the effective diffusion coefficient. This is observed for both hydrogen pre-charged samples (closed-systems) and samples exposed to a permanent source of hydrogen (open-systems). Experiments are used to determine the critical concentration for embrittlement, by mapping the range of frequencies where the output is the same as testing in inert environments. We then quantitatively investigate and discuss the implications of developing materials with higher trap densities in mitigating embrittlement in the presence of cyclic loads. It is shown that, unlike the static case, increasing the density of “beneficial traps” is a viable strategy in designing alloys resistant to hydrogen assisted fatigue for both closed- and open-systems.

ACTA Vol. 199, 15 Oct. 2020, P278-287

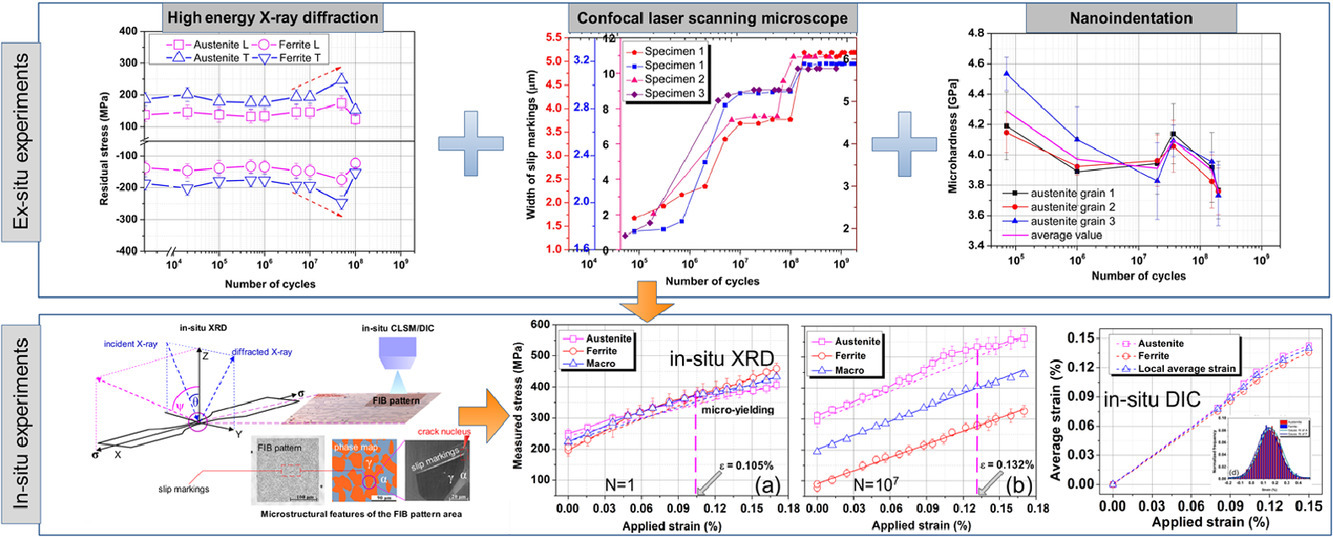

17. Microcrack initiation mechanism of a duplex stainless steel under very high cycle fatigue loading condition: The significance of load partitioning and micro residual stresses

載荷配分和微殘余應力對雙相不銹鋼高周疲勞載荷下微裂紋萌生過程的影響

Hongwang Fu?, Benjamin Dönges, Ulrich Krupp, Ullrich Pietsch, Claus-Peter Fritzen, Xinbing Yun, Hans-Jürgen Christ?

H. Fu:hongwangfu@djtu.edu.cn

H.-J. Christ:Hans-Juergen.Christ@unisiegen.de

https://doi.org/10.1016/j.actamat.2020.08.042

摘要

金屬材料在超高周疲勞(VHCF)下的響應長期以來一直是疲勞理論中一個富有挑戰性的問題。我們采用了幾種敏感性較高的技術手段,如高能X射線衍射(HEXRD)、激光共聚焦掃描顯微鏡(CLSM)、納米壓痕、透射電子顯微鏡(TEM)等,對雙相不銹鋼(DSS)在超高周疲勞下的響應進行了研究。隨后我們在觀測到的變化階段對樣品進行了原位XRD和 DIC實驗,以研究微裂紋的萌生機制。實驗結果表明,材料中的奧氏體相在VHCF過程中表現出了反復的軟化-硬化-軟化行為。原位實驗表明,在這一階段,兩相之間存在應力配分和應力轉移,這說明循環過程會顯著影響外加載荷在材料中的分布。DIC結果表明,卸載后的殘余應變在相界處表現出強烈的變化,說明微殘余應力發生了明顯增長。在此基礎上,我們提出了一種VHCF加載下DSS的統一裂紋萌生機制。

英文摘要

Investigation on the cyclic response of metallic materials in very high cycle fatigue (VHCF) is a challenging problem, which hinders the development of fatigue theories. To overcome this difficulty, we initially applied several sensible techniques, e.g., High-energy X-ray diffraction (HEXRD), confocal laser scanning microscope (CLSM), nanoindentation and transmission electron microscope (TEM) to investigate the cyclic response of a duplex stainless steel (DSS) in the VHCF regime. In-situ XRD and in-situ digital image correlation (DIC) experiments were subsequently performed at observed changing stages, intending to explore the underlying mechanism of microcrack initiation. The first-hand results obtained revealed that the austenite phase exhibits cyclic softening-hardening-softening behavior during the VHCF process. The in-situ investigations performed at the cyclic softening and hardening stages showed a load partitioning and a load transfer between the two phases, implying the cyclic response can significantly affect the distribution of the applied load. Residual strain obtained by DIC technique after unloading exhibited strong variations at phase boundaries, suggesting micro residual stresses have developed pronouncedly. Based on all the experimental findings, a unified crack initiation mechanism for the investigated DSS during VHCF loading was proposed.

微信公眾號:Goal Science

投稿郵箱:wechat@gs-metals.com

投稿微信:GSmaterial