金屬頂刊雙語導讀丨Scripta Mater. Vol.191, 15 Jan. 2021(下)

2020-10-29 來源: Goal Science

本期包含金屬材料領域論文11篇,涵蓋了高熵合金、納米析出鋼、純鈦、鈦合金、鎂鋁合金等,國內科研單位包括香北京理工大學、沖擊環境材料技術國家級重點實驗室、東北大學、北京航空航天大學、南京理工大學等(通訊作者單位)。

Vol. 191 目錄

SCRIPTA Vol. 191, 15 Jan. 2021, P126-130

13. Observation of Mn-Ni-Si-rich features in thermally-aged model reactor pressure vessel steels

熱時效模型反應堆壓力容器鋼中富錳-鎳-硅特征的觀察

B.M. Jenkins?, P.D. Styman?, N. Riddle, P.A.J. Bagot, M.P. Moody, G.D.W. Smith, J.M. Hyde

B.M. Jenkins: benjamin.jenkins@materials.ox.ac.uk

P.D. Styman: paul.d.styman@uknnl.com

https://doi.org/10.1016/j.scriptamat.2020.09.029Get

摘要

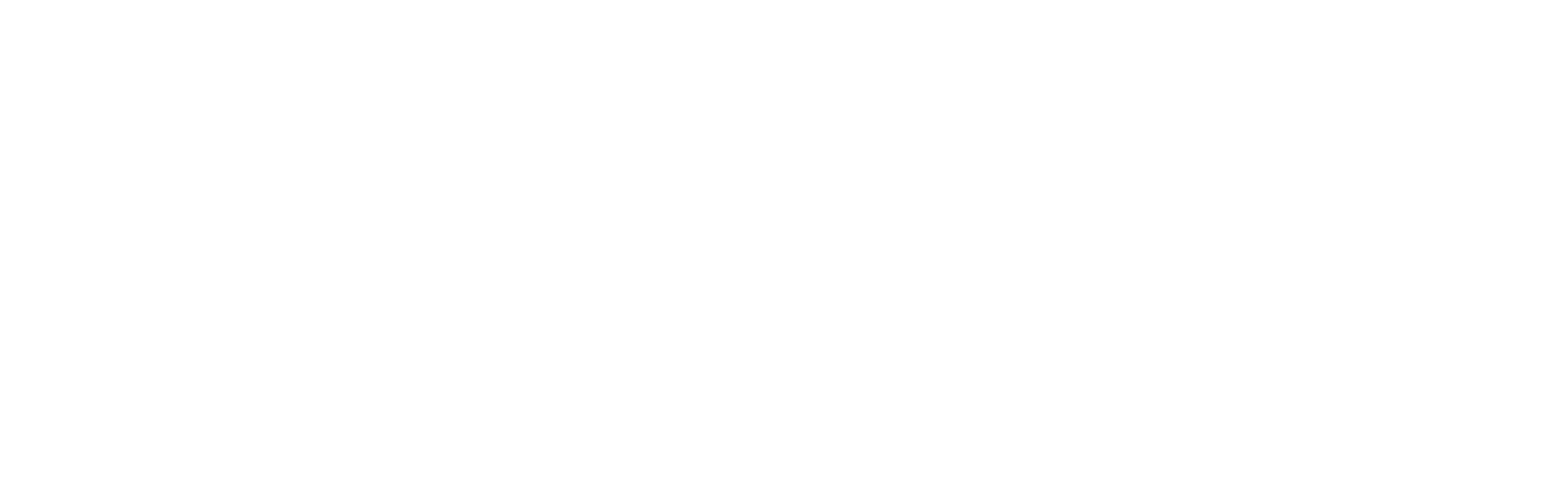

我們用原子探針層析成像技術表征了長期熱時效后的兩個低銅(< 0.04 at.%)模型鋼。研究發現,在短短20731小時(~2.4年)的時效后,就會形成富含錳鎳硅的特征。我們將這些特征的成分與熱力學模型的預測結果進行了比較,并討論了它們的異同。

英文摘要

Atom probe tomography was used to characterise two low-Cu (< 0.04 at. %) model steels after exposure to long-term thermal ageing. Mn-Ni-Si-rich features were observed to form after as little as 20,731 h (∼ 2.4 years) of ageing. The composition of these features were compared to those predicted by thermodynamic models and the similarities and differences are discussed.

SCRIPTA Vol. 191, 15 Jan. 2021, P131-136

14. Designing VxNbMoTa refractory high-entropy alloys with improved properties for high-temperature applications

設計VxNbMoTa耐火高熵合金,改善高溫服役性能

M. Wang, Z.L. Ma?, Z.Q. Xu, X.W. Cheng?

Z.L. Ma: z.l.ma@bit.edu.cn,北京理工大學,沖擊環境材料技術國家級重點實驗室

X.W. Cheng: chengxw@bit.edu.cn,北京理工大學,沖擊環境材料技術國家級重點實驗室

https://doi.org/10.1016/j.scriptamat.2020.09.027

摘要

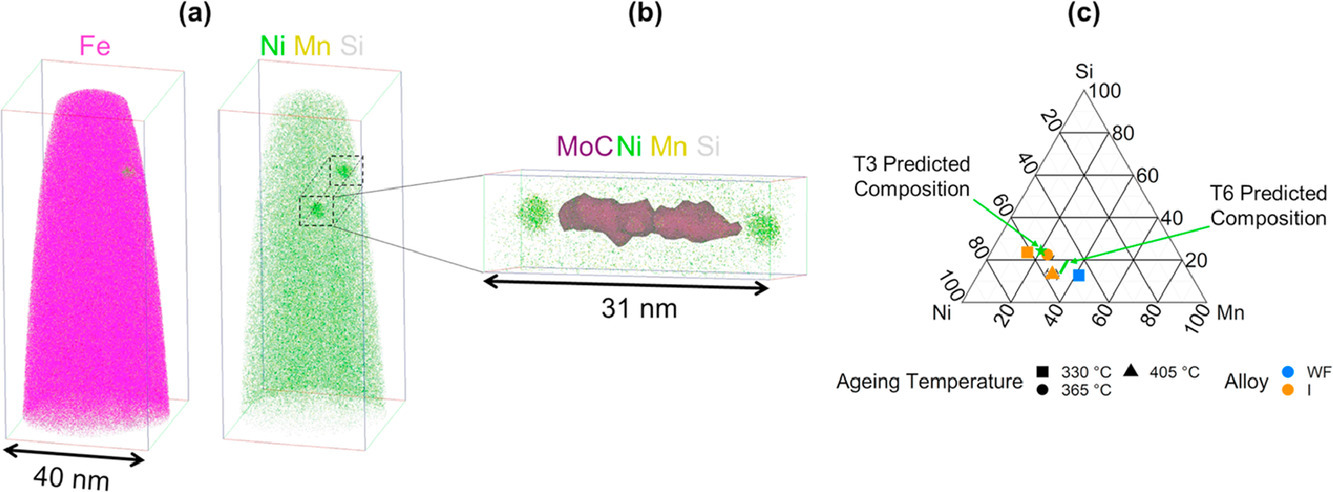

高/中溫相穩定性差和/或室溫塑性低是目前制約耐火高熵合金高溫應用的瓶頸。在本工作中,我們探索了釩濃度為0-25at .%的新型VxNbMoTa耐火高熵合金。VxNbMoTa耐火高熵合金呈現出單一體心立方(BCC)結構,在固相線到350℃的寬溫度范圍內具有前所未有的相穩定性。隨著釩濃度的增加,VxNbMoTa的晶粒結構可以得到充分細化,因為較高的釩含量會誘發更強的溶質效應,從而導致更高的生長限制因子。等摩爾比的VNbMoTa樣品的屈服強度在1000℃條件下為811MPa,優于目前報道的大多數耐火高熵合金。該合金也表現出良好的室溫塑性,斷裂應變為> 25%,在高溫下沒有應變軟化現象,這在眾多耐火高熵合金中是少見的。VNbMoTa合金的優異性能使其成為一種非常有前途的高溫應用材料。

英文摘要

Poor high/medium-temperature phase stability and/or low room-temperature ductility are currently bottlenecks of refractory high-entropy alloys (RHEAs) that restrict their high-temperature applications. Here, we explored novel VxNbMoTa RHEAs with vanadium concentrations of 0–25 at.%. VxNbMoTa RHEAs exhibit a single body-centered cubic (BCC) structure with unprecedented phase stability at a wide temperature range from solidus down to 350°C. The grain structure of VxNbMoTa can be substantially refined when increasing the V concentration since higher V contents induce stronger solutal effects which contribute to higher growth restriction factors. Equimolar VNbMoTa exhibits the yield strength of 811 MPa at 1000°C that is superior to most RHEAs reported by far, and this alloy also shows excellent room-temperature ductility with the fracture strain > 25% and no strain-softening at high temperature, which is rarely seen in many popular RHEAs. These exceptional performances of VNbMoTa enable it to be a very promising material for high-temperature applications.

SCRIPTA Vol. 191, 15 Jan. 2021, P137-142

15. A novel strategy for hierarchical structure in multicomponent nano-precipitated steels by high magnetic field aging

利用高磁場時效制備多組元納米析出鋼分層結構的新策略

Nianshuang Qiu, Jiacheng Yan, Xiaowei Zuo?

Xiaowei Zuo: zuoxw@epm.neu.edu.cn,東北大學

https://doi.org/10.1016/j.scriptamat.2020.09.035

摘要

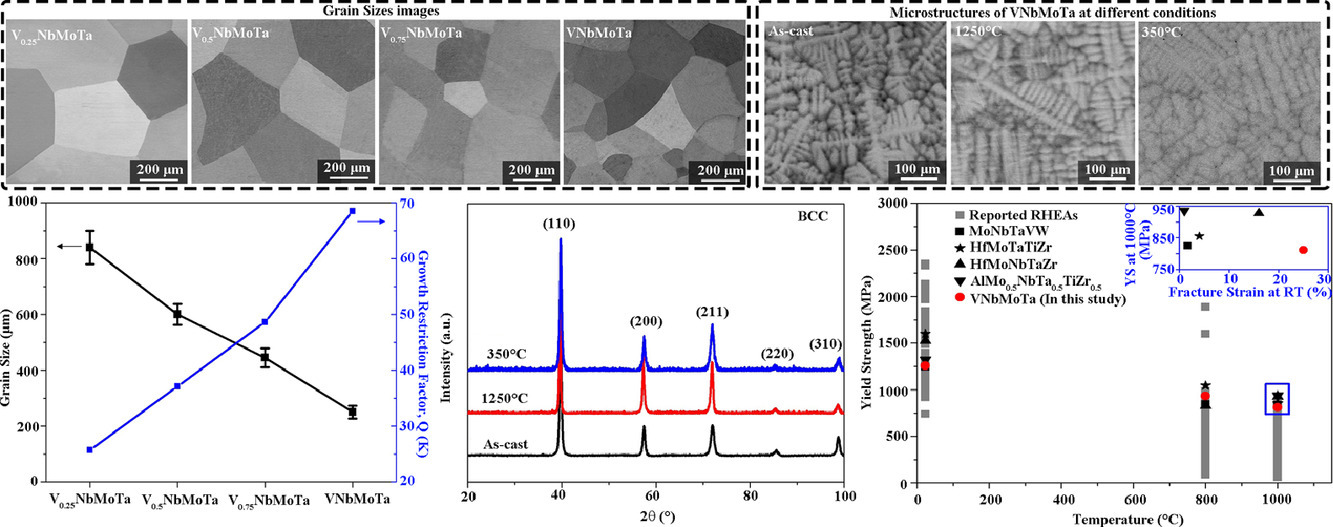

本工作研究了時效過程中強磁場(HMF)對多組元納米鋼中富銅析出和Ni(AlMn)析出的共析出行為的影響。結果表明,HMF促進了富銅和Ni(AlMn)共析出的分層結構的構建。研究認為,時效過程中,由于熱力學的變化,HMF增加了二次共析出的形核速率,從而細化了二次析出。同時,在回火后的進一步時效過程中,由于Cu的擴散速率增加,HMF提高了初生顆粒的奧斯瓦爾德熟化速率,從而加速了粗化過程。

英文摘要

The influence of high magnetic field (HMF) during aging on the precipitation behavior of co-precipitates consisted of Cu-rich precipitates and Ni(AlMn) precipitates in multicomponent nano-precipitated steels was carefully investigated. It was indicated that HMF promoted the construction of hierarchical structures of Cu-rich and Ni(AlMn) co-precipitates. It was thought that HMF increased nucleation rates of secondary co-precipitates during aging because of the thermodynamics change, thus refining the secondary precipitates. Meanwhile, HMF increased the Ostwald ripening rate of primary particles during the further aging after tempering because of increasing diffusion of Cu, thus accelerating the coarsening process.

SCRIPTA Vol. 191, 15 Jan. 2021, P155-160

16. Achieving high ductility in a selectively laser melted commercial pure-titanium via in-situ grain refinement

通過原位晶粒細化,在選區激光熔化制備的商用純鈦中實現高延展性

Jingqi Zhang, Yingang Liu, Mohamad Bayat, Qiyang Tan, Yu Yin, Zhiqi Fan, Shiyang Liu, Jesper Henri Hattel, Matthew Dargusch, Ming-Xing Zhang?

Ming-Xing Zhang: mingxing.zhang@uq.edu.au

https://doi.org/10.1016/j.scriptamat.2020.09.023

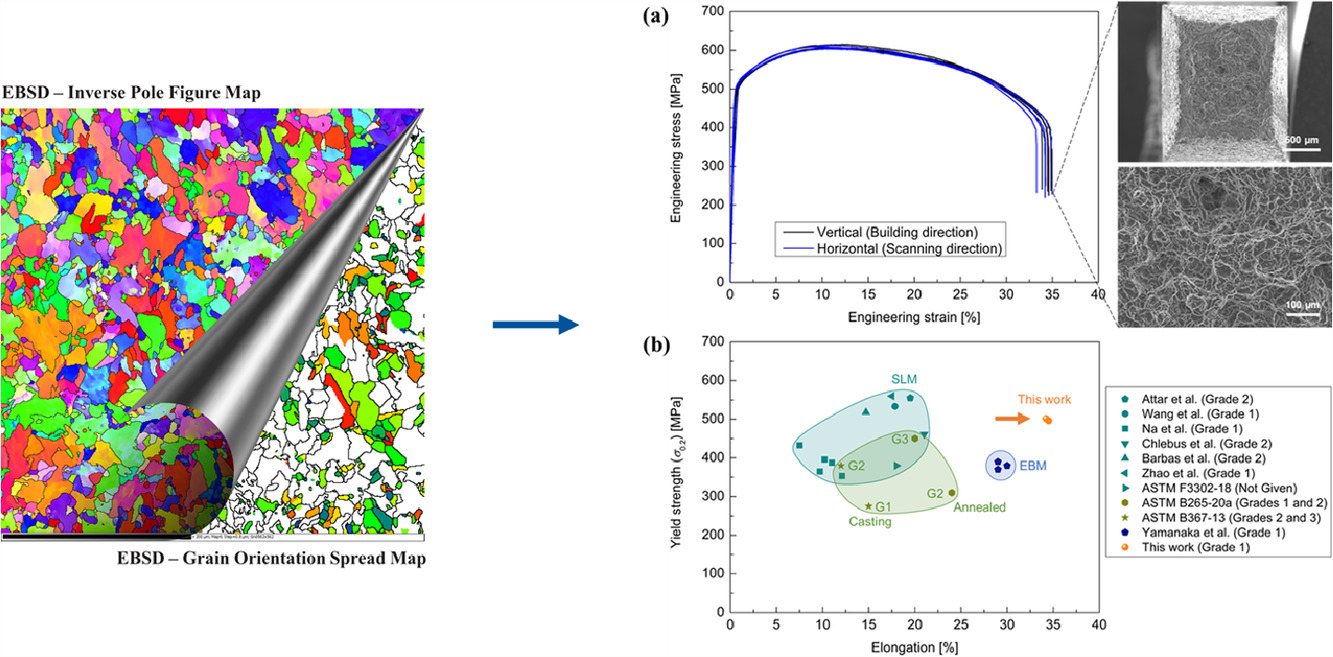

摘要

添加異質元素或顆粒可以促進增材制造鈦和鈦合金的晶粒細化,但由于脆性金屬間化合物的形成會導致延展性的降低。本研究表明,通過適當控制選區激光熔化(SLM)的參數,可以實現工業純鈦(CP-Ti)的原位晶粒細化。研究發現,較高的能量輸入密度有利于晶粒細化。通過詳細的微觀組織表征和多物理場模擬,揭示了晶粒細化的機理。這歸因于SLM工藝固有的循環再加熱導致的本征熱處理(IHT)效應。細化的CP-Ti表現出34.3±0.5%的極高延展性,沒有明顯的機械各向異性。這項工作證明了在不改變化學成分的條件下,利用增材制造(AM)的熱循環來細化金屬晶粒的可行性。

英文摘要

Grain refinement of additively manufactured titanium and titanium alloys can be promoted via adding foreign elements or particles, but it may lead to a reduction in ductility due to the formation of brittle intermetallic compounds. The present study shows that in-situ grain refinement of commercially pure titanium (CP-Ti) can be achieved through properly controlling the selective laser melting (SLM) parameters. It was found that higher input energy density worked in favour of grain refinement. Detailed microstructural characterization coupled with multi-physics simulation were performed to reveal the grain refinement mechanism. This was attributed to the intrinsic heat treatment (IHT) effect which resulted from the cyclic reheating inherent to the SLM process. As a result, the refined CP-Ti exhibited an exceptionally high ductility of 34.3 ± 0.5% without notable mechanical anisotropy. This work demonstrates the feasibility of utilizing thermal cycling of additive manufacturing (AM) to refine grains of metals without changing the composition.

SCRIPTA Vol. 191, Jan. 2021, P29-33

17. Achieving improved workability and competitive high temperature shape memory performance by Nb addition to Ni-Ti-Hf alloys

通過在Ni-Ti-Hf合金中添加Nb來提高其可加工性和優異的高溫形狀記憶性能

J.N. Lemke, F. Gallino, M. Cresci, A. Coda?

A. Coda: Alberto_Coda@saes-group.com

https://doi.org/10.1016/j.scriptamat.2020.09.032

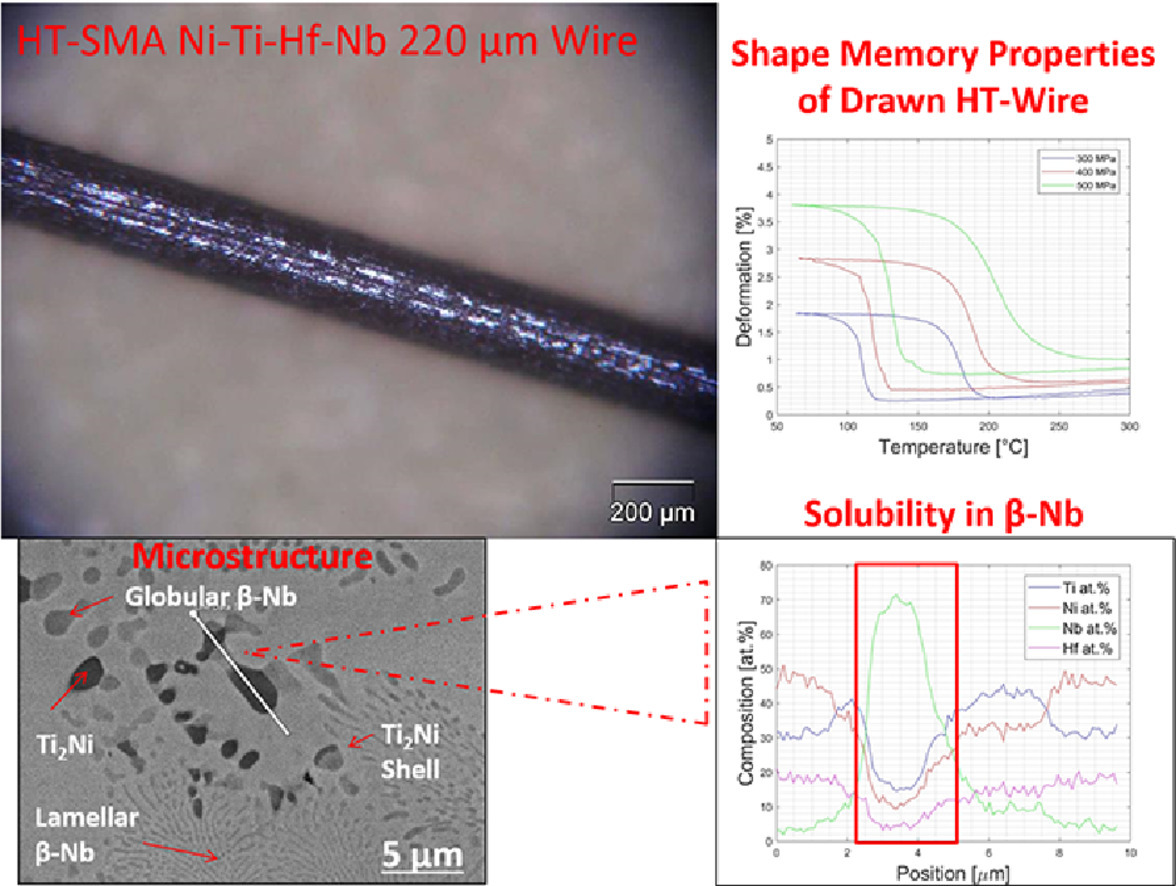

摘要

本工作描述了鈮如何在不明顯影響功能性的情況下提高Ni-Ti-Hf合金的延展性,這是由于由軟β-Nb和B19’ Ni-Ti-Hf基體相組成的共晶組元的形成。設計高性能Ni-Ti-Hf-Nb合金的關鍵是考慮Nb在基體中的低溶解度以及β-Nb中元素的不同溶解度對轉變溫度的影響。通過對拉拔Ni-Ti-Hf-Nb絲的實例研究表明,該方法可以改善力學性能,提高轉變溫度,增加高溫形狀記憶合金拉絲的可能性。

英文摘要

This work depicts how Nb addition to Ni-Ti-Hf alloys increases their ductility without significantly deviating functional performance due to the formation of eutectic constituents composed of soft β-Nb and B19’ Ni-Ti-Hf matrix phase. Crucial for designing high performing Ni-Ti-Hf-Nb alloys is considering consequences of the low solubility of Nb in the matrix and the varying solubility of elements in β-Nb on the transformation temperatures. A case study on a drawn Ni-Ti-Hf-Nb wire demonstrates that improved mechanical properties and high transformation temperatures can be achieved by this approach, increasing the possibility for wire drawing of high temperature shape memory alloys.

SCRIPTA Vol. 191, 15 Jan. 2021, P173-178

18. Effects of annealing on hardness, yield strength and dislocation structure in single crystals of the equiatomic Cr-Mn-Fe-Co-Ni high entropy alloy

退火對等原子Cr-Mn-Fe-Co-Ni單晶高熵合金硬度、屈服強度和位錯結構的影響

Dengshan Zhou?, Zhenghao Chen, Kazuki Ehara, Kodai Nitsu, Katsushi Tanaka, Haruyuki Inui

Dengshan Zhou: zhoudengshan@mail.neu.edu.cn,京都大學,中國東北大學,德國馬普所

https://doi.org/10.1016/j.scriptamat.2020.09.039

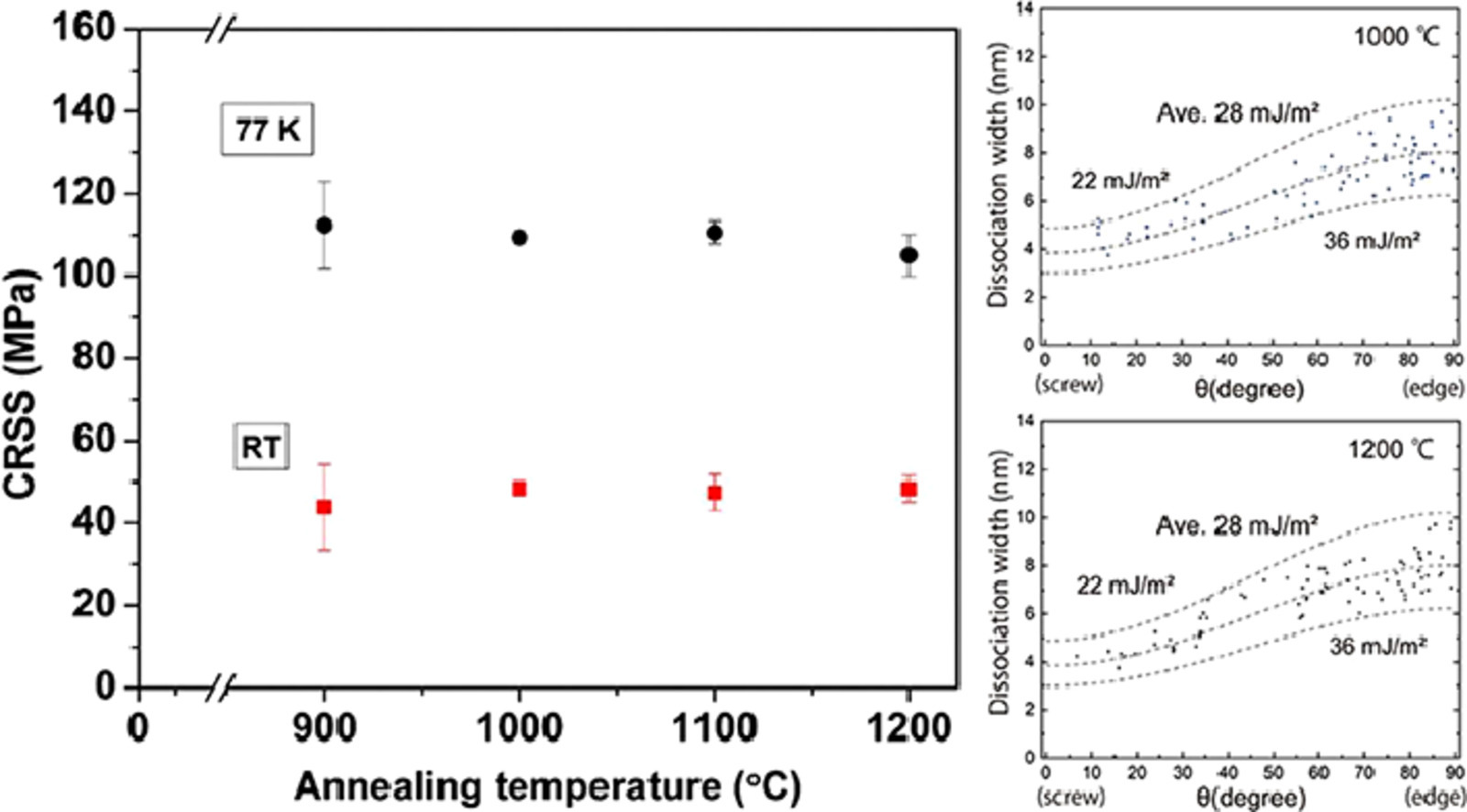

摘要

與預期相反,我們報告了面心立方單相等原子Cr-Mn-Fe-Co-Ni高熵合金的宏觀力學強度不受退火的影響,在退火期間可能形成了短程有序結構。實驗結果表明,室溫硬度、室溫和77 K下的臨界分切應力以及合金的激活體積值在900-1200℃退火后不發生明顯變化。在1000℃和1200℃退火后的樣品,77K下變形的層錯能基本相同。這些結果清晰地表明,化學短程有序的形成即使存在,對等原子Cr-Mn-Fe-Co-Ni高熵合金宏觀屈服強度的影響也不明顯。

英文摘要

We report that in contrast to the anticipation, the macroscopic mechanical strength of single crystals of the face-centered-cubic single-phase equiatomic Cr-Mn-Fe-Co-Ni high entropy alloy is not influenced by thermal annealing during which short-range ordering is expected to develop. Experimental evidence shows that hardness at room temperature, critical resolved shear stress at room temperature and at 77 K and activation volume values of the alloys do not significantly vary with the annealing temperature in the range from 900 to 1200°C. The stacking fault energies in the specimens deformed at 77 K following annealing at 1000 and 1200°C respectively are essentially identical to each other. These results clearly indicate that the impact of the formation of chemical short-range order on the macroscopic yield strength of the equiatomic Cr-Mn-Fe-Co-Ni high entropy alloy is insignificant, even if it exists.

SCRIPTA Vol. 191, 15 Jan. 2021, P185-190

19. Stress-driven grain refinement in a microstructurally stable nanocrystalline binary alloy

微觀結構穩定的二元納米晶合金中的應力驅動晶粒細化

K.A. Darling?, S. Srinivasan, R.K. Koju, B.C. Hornbuckle, J. Smeltzer, Y. Mishin, K.N. Solanki?

K.A. Darling: kristopher.a.darling.civ@mail.mil

K.N. Solanki: Kiran.solanki@asu.edu

https://doi.org/10.1016/j.scriptamat.2020.09.041

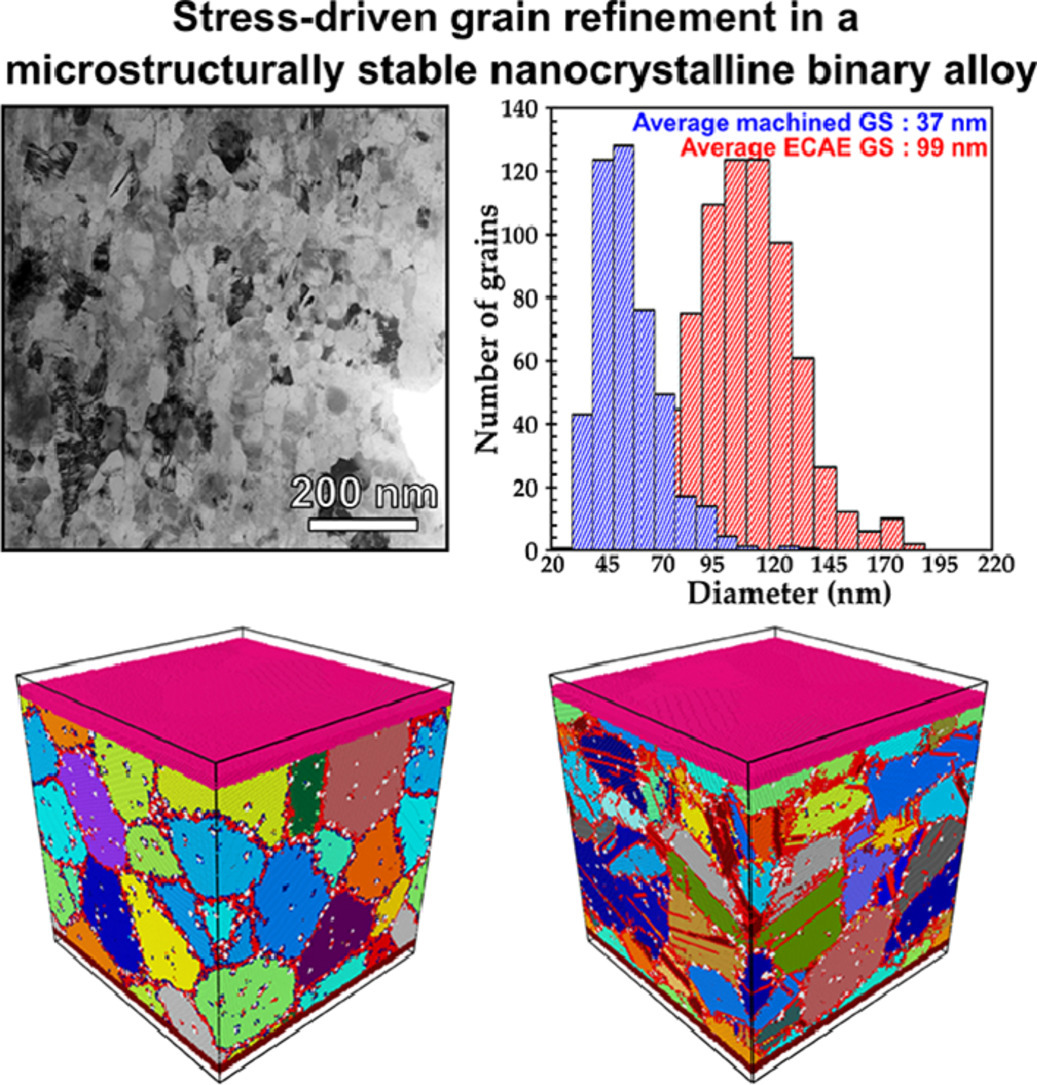

摘要

納米晶材料中形變誘導晶粒生長是一種被廣泛報道的現象,這種現象歸因于晶界過程。在本文中,我們報告了與之相反的現象,即穩定的納米晶銅-鉭合金在嚴重塑性變形 (SPD) 過程中納米晶粒得到進一步細化。盡管變形過程中溫度升高了350℃,但當SPD達到250%時,會導致晶粒尺寸顯著減小。實驗和原子模擬表明,這種意想不到的晶粒細化是由于彌散分布的鉭納米團簇在整個晶粒中心和沿晶界分布的直接結果。這些鉭納米團簇充當了動力學釘扎劑,抑制了再結晶過程中的晶界過程。

英文摘要

Deformation-induced grain-growth in nanocrystalline materials is a widely-reported phenomenon that has been attributed to grain boundary (GB) processes. In this paper, we report on the opposite phenomenon, wherein a stable nanocrystalline (NC) Cu-Ta alloy undergoes a further refinement of the nano-grains during severe plastic deformation (SPD). SPD up to 250% results in a significant grain-size reduction despite the 350°C increase in temperature caused by the deformation process. Experiments and atomistic-simulations show that this unexpected grain-refinement is a direct result of well-dispersed Ta-nanoclusters throughout grain centers and along GBs acting as kinetic-pinning agents and suppressing GB processes that occur during recrystallization.

SCRIPTA Vol. 191, 15 Jan. 2021, P191-195

20. A robust algorithm to calculate parent β grain shapes and orientations from α phase electron backscatter diffraction data in α/β-titanium alloys

根據α/β-鈦合金中α相電子背散射衍射數據計算母體β晶粒形狀和取向的可靠算法

Alexander Zaitzeff?, Adam Pilchak, Tracy Berman, John Allison, Selim Esedoglu

Alexander Zaitzeff: azaitzef@umich.edu

https://doi.org/10.1016/j.scriptamat.2020.09.038

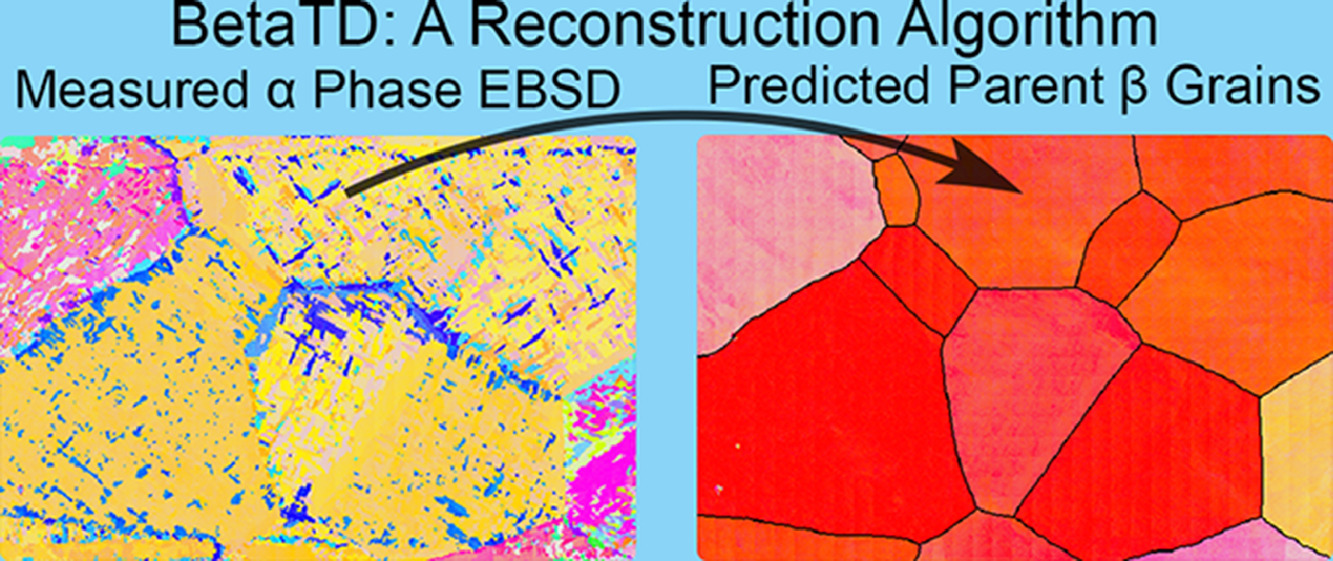

摘要

本文提出了一種新的模型和開源算法,該模型和算法可從測量的α/β鈦合金中的α相電子背散射衍射數據中重建原β相的取向和晶粒形狀。它基于Mumford和Shah的圖像分割模型,包括一個正則化因子,用來創建平滑邊界并克服了現有重建技術的缺點。此外,該新算法具有很強的抗噪性。我們的算法在模擬和真實數據上均具有有效性。

英文摘要

This paper presents a new model and open-source algorithm for reconstructing prior β phase orientation and grain shapes from measured α-phase electron backscatter diffraction data in α/β titanium alloys. It is based on the image segmentation model of Mumford and Shah, which includes a regularization term that helps create smooth boundaries and overcomes shortcomings of prior reconstruction techniques. Additionally, the new algorithm is resilient to noise. Our algorithm’s effectiveness is demonstrated on simulated and real world data.

SCRIPTA Vol. 191, 15 Jan. 2021, P196-201

21. Simultaneously enhanced strength and strain hardening capacity in FeMnCoCr high-entropy alloy via harmonic structure design

通過調和結構設計,同時提高了FeMnCoCr高熵合金的強度和應變硬化能力

Guodong Li, Maowen Liu, Shaoyuan Lyu, Masashi Nakatani, Ruixiao Zheng?, Chaoli Ma, Qiushi Li, Kei Ameyama

Ruixiao Zheng: zhengruixiao@buaa.edu.cn,北京航空航天大學

https://doi.org/10.1016/j.scriptamat.2020.09.036

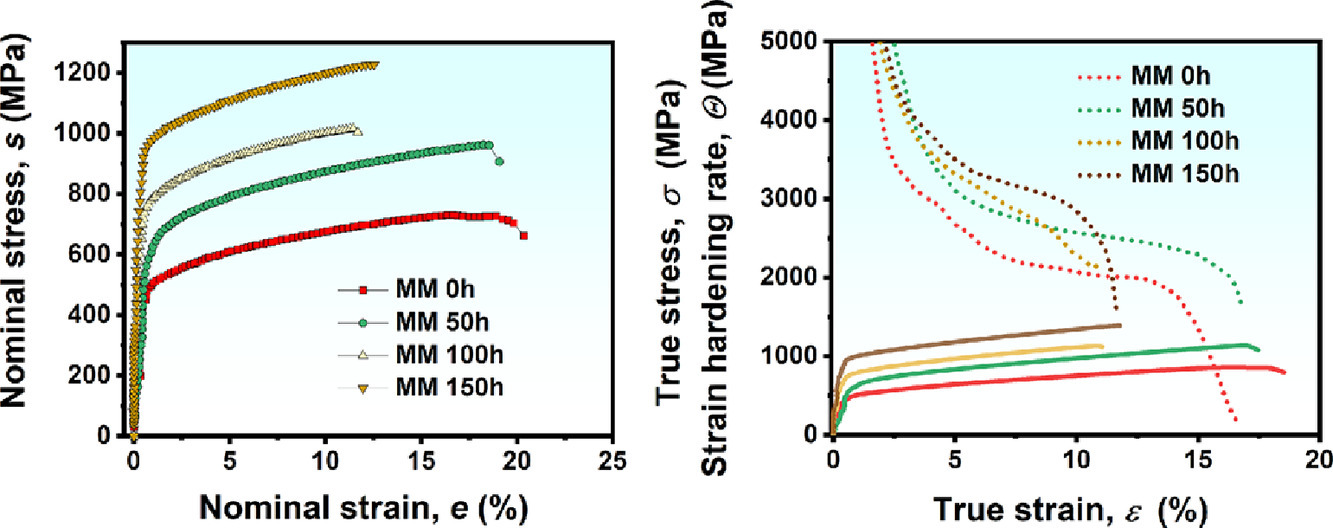

摘要

調和結構(HS)被認為是一種有效的微觀組織設計策略,可以提高金屬材料的強度和延展性,其結構特點為粗晶(CG)區域均勻嵌入三維連續的超細晶(UFG)區域。本研究通過可調控的機械球磨和隨后的燒結過程,成功制備了具有HS特征的非等原子FeMnCoCr高熵合金樣品,其中shell的體積分數可調(從~16%到~70%)。微觀組織觀察表明,shell區域由完全再結晶的UFG組成,平均晶粒尺寸小于1µm。拉伸試驗表明,與均質結構試樣相比,具有HS特征的試樣的強度和應變硬化能力同時得到提高。特別是,shell體積分數約為70%的樣品的抗拉強度和均勻伸長率分別為1228MPa和12.4%,表現出優異的強度-塑性協同作用。本文討論了力學性能強化的潛在機理。

英文摘要

Harmonic structure (HS), consisting of coarse-grained (CG) areas uniformly embedded in three dimensional continuously connected ultrafine-grained (UFG) areas, is considered as an effective microstructural design strategy to achieve enhanced strength and ductility in metallic materials. In the present study, HS designed non-equiatomic FeMnCoCr high-entropy alloy samples with tunable shell fractions (ranging from ~16% to ~70%) were successfully prepared via controlled mechanical milling and subsequent sintering. Microstructure observations suggested that the shell region was composed of fully recrystallized UFGs with a mean grain size below 1 µm. Tensile test revealed that the HS designed samples exhibited simultaneously enhanced strength and strain hardening capability than those of the homogeneous structured counterpart. Particularly, the ultimate tensile strength and uniform elongation of the sample with a shell fraction of ~70% were 1228MPa and 12.4%, respectively, demonstrating superior strength-ductility synergy. The underlying mechanisms responsible for the enhanced mechanical properties were discussed.

SCRIPTA Vol. 191, 15 Jan. 2021, P215-218

22. Surface activated bonding of aluminum oxide films at room temperature

室溫下氧化鋁膜的表面活化鍵合

Jun Utsumi, Ryo Takigawa?

Ryo Takigawa: takigawa@ed.kyushu-u.ac.jp

https://doi.org/10.1016/j.scriptamat.2020.09.005

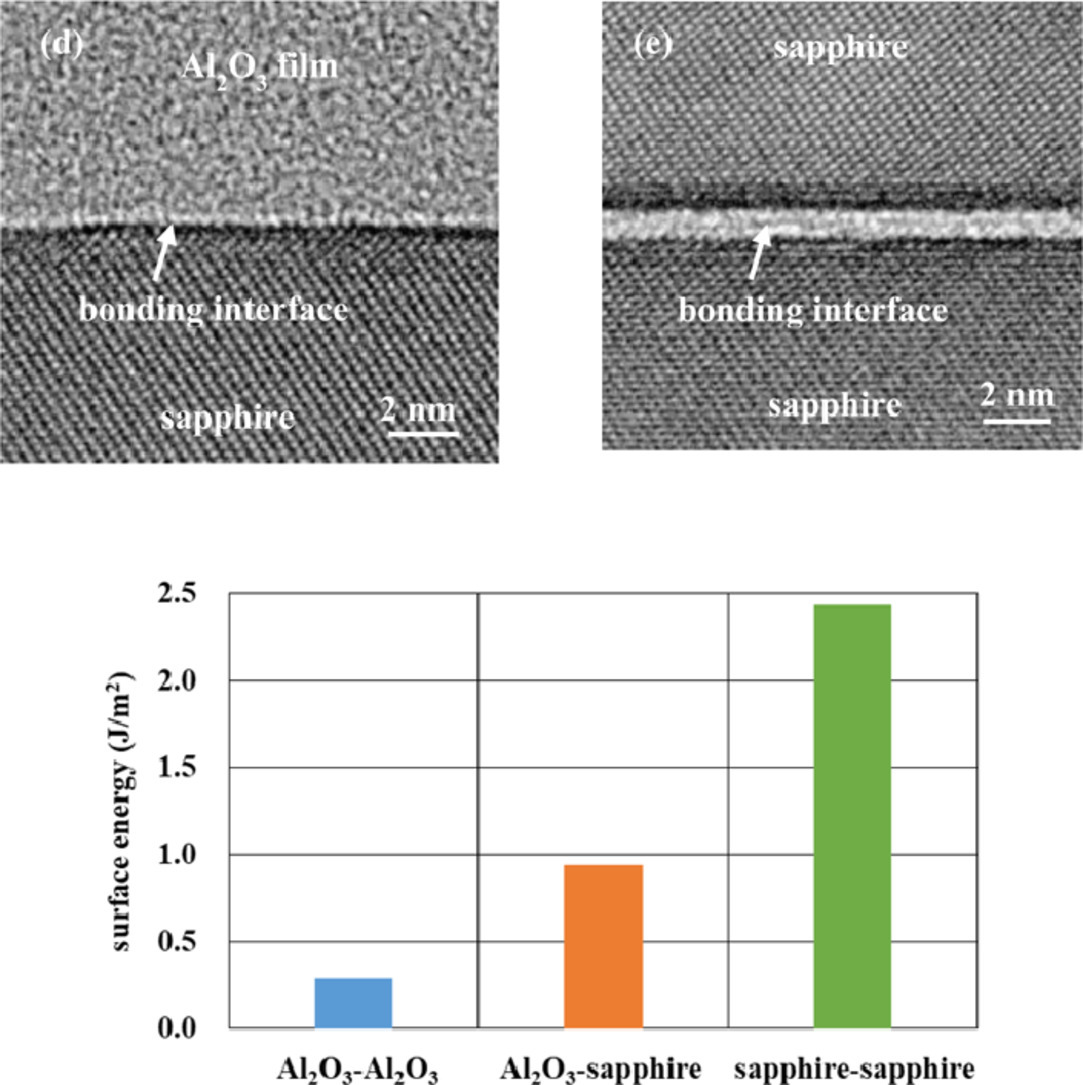

摘要

我們采用化學氣相沉積的方法研究了在室溫短時間活化條件下沉積氧化鋁薄膜的表面活化鍵合行為。雖然Al2O3膜成鍵的表面能很低,但Al2O3膜/藍寶石成鍵的表面能約為1 J m-2,藍寶石/藍寶石成鍵的表面能大于2 J m-2。透射電鏡結果顯示在Al2O3/Al2O3鍵合界面出現了約1nm厚的非晶狀中間層,而在Al2O3/藍寶石鍵合界面則沒有觀察到。此種現象表明Al2O3膜的結晶度會影響Al2O3的鍵合。

英文摘要

We have investigated the surface activated bonding (SAB) of deposited Al2O3 films by chemical vapor deposition under a short-time activated condition at room temperature. Although the surface energy for bonding of Al2O3 films was very low, that of Al2O3 film/sapphire bonding was approximately 1 J m-2 and more than 2 J m-2 for sapphire/sapphire bonding. Transmission electron microscopy showed an amorphous-like intermediate layer approximately 1 nm thick, observed at the bonding interface of Al2O3/Al2O3, but not in the bonding of Al2O3/sapphire, which suggests that the crystallinity of the Al2O3 film affects the bonding of Al2O3.

SCRIPTA Vol. 191, 15 Jan. 2021, P219-224

23. Effect of dislocation configuration on Ag segregation in subgrain boundary of a Mg-Ag alloy

位錯構型對Mg-Ag合金中亞晶界處銀偏析的影響

Lirong Xiao, Xuefei Chen, Kang Wei, Yi Liu, Dongdi Yin, Zhaohua Hu, Hao Zhou?, Yuntian Zhu?

Hao Zhou: hzhou511@njust.edu.cn,南京理工大學

Yuntian Zhu: ytzhu@ncsu.edu,南京理工大學,北卡羅萊納州立大學

https://doi.org/10.1016/j.scriptamat.2020.08.040

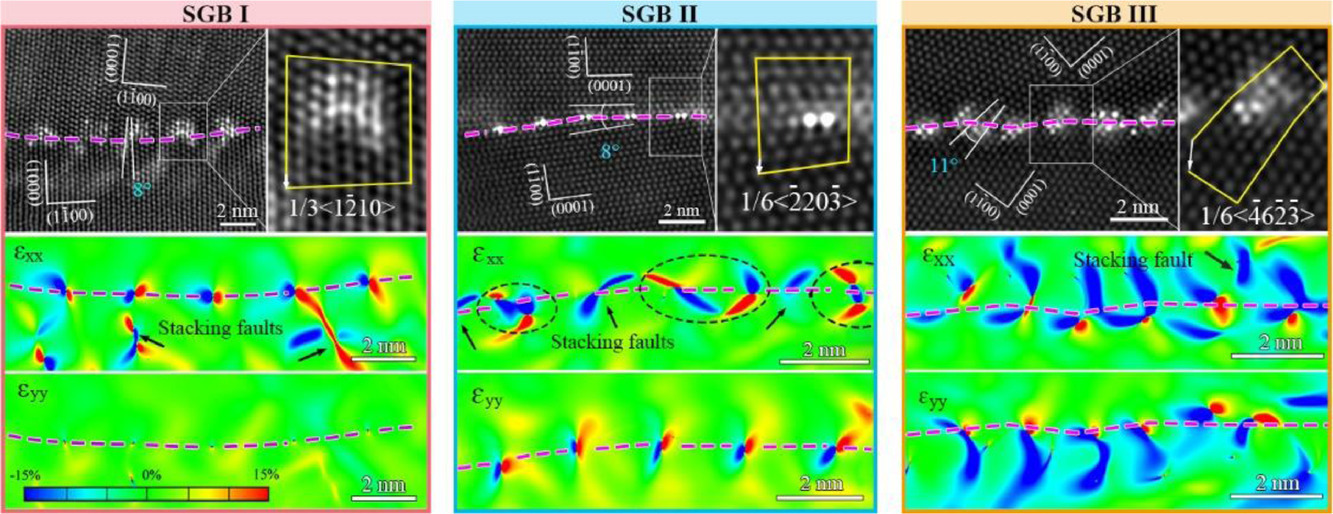

摘要

界面偏析對納米晶鎂合金的熱機械穩定性起著至關重要的作用。本文報道了傳統軋制過程中銀偏聚輔助形成高比例亞晶界的鎂銀納米晶合金。偏析結構是由位錯構型、應變場和亞晶界的取向差決定的。這表明,誘導<c+a>位錯的合金元素有助于提高界面的穩定性。

英文摘要

Interfacial segregation has been reported to play a critical role in the thermal-mechanical stability of nanocrystalline Mg alloys. Here we report Ag-segregation-assisted formation of nanocrystalline Mg-Ag alloy with high proportion of sub-grain boundaries during conventional rolling. The segregation structure is determined by dislocation configurations and subsequent strain field and misorientation of the sub-grain boundary. It indicates that the alloying elements, which induce <c+a> dislocations, would help to improve the stability of interfaces.

微信公眾號:Goal Science

投稿郵箱:wechat@gs-metals.com

投稿微信:GSmaterial