金屬頂刊雙語導讀丨Acta Mater. Vol.200,Nov. 2020(中)

2020-12-21 來源:Goal Science

本期包含金屬材料領域論文17篇,涵蓋了鋁合金、中錳鋼、鈦鋁合金、鎢合金、鋯合金、鎂合金等,國內科研單位包括清華大學、北京科技大學等(通訊作者單位)。

Vol. 200 目錄

26. Coupled solute effects enable anomalous high-temperature strength and stability in nanotwinned Al alloys

耦合溶質效應使納米鋁合金具有反常的高溫強度和穩定性

27. Phase boundary segregation-induced strengthening and discontinuous yielding in ultrafine-grained duplex medium-Mn steels

超細晶雙相中錳鋼的相邊界偏析強化和不連續屈服

28. The role of crystallographic texture on mechanically induced grain boundary migration

晶體學織構對機械誘導晶界遷移的作用

29. On the nature of hexagonality within the solidification structure of single crystal alloys: Mechanisms and applications

關于單晶合金凝固組織中六邊形的性質:機理和應用

30. Wear-induced microstructural evolution of nanocrystalline aluminum and the role of zirconium dopants

納米鋁的磨損誘導組織演變及鋯摻雜的作用

31. High-temperature phenomena in an advanced intermetallic nano-lamellar γ-TiAl-based alloy. Part I: Internal friction and atomic relaxation processes

先進的金屬間化合物納米層狀γ-TiAl基合金的高溫現象。第一部分:內耗和原子弛豫過程

32. Atomistic view onto solid state dewetting: Thin bismuth films with and without strain gradient

固態去濕的原子論觀點:有應變梯度和無應變梯度的鉍薄膜

33. Mechanical degradation due to vacancies produced by grain boundary corrosion of steel

鋼鐵材料中因晶界腐蝕產生空位導致的機械性能劣化

34. Screw dislocation-carbon interaction in BCC tungsten: an ab initio study

BCC鎢合金中螺位錯與碳相互作用的第一性原理模擬計算

35. Critical nuclei at hetero-phase interfaces

異質界面的臨界形核

36. Slip–hydride interactions in Zircaloy-4: Multiscale mechanical testing and characterisation

Zircaloy-4鋯合金中滑移和氫化物相互作用的多尺度力學測試和表征

37. Impact of magnetism on screw dislocations in body-centered cubic chromium

磁場對體心立方鉻螺位錯的影響

38. Characterisation of deuterium distributions in corroded zirconium alloys using high-resolution SIMS imaging

經腐蝕后鋯合金中氘分布的高分辨SIMS表征

39. Incomplete carbon partitioning during quenching and partitioning of Fe–C–Mn–Si steels: Modeling and experimental validations

Fe–C–Mn–Si鋼淬火-配分過程中不完全碳配分現象的模擬和實驗驗證

40. A rationale for the influence of grain size on failure of magnesium alloy AZ31: An in situ X-ray microtomography study

晶粒尺寸對AZ31鎂合金失效影響的原位X射線研究

41. Effect of solute-solute interactions on strengthening of random alloys from dilute to high entropy alloys

溶質原子相互作用對隨機合金的強化作用

42. Atomic-scale investigation of deep hydrogen trapping in NbC/α-Fe semi-coherent interfaces

NbC/α-Fe半共格界面氫陷阱的原子尺度研究

ACTA Vol. 200,Nov. 2020, P378-388

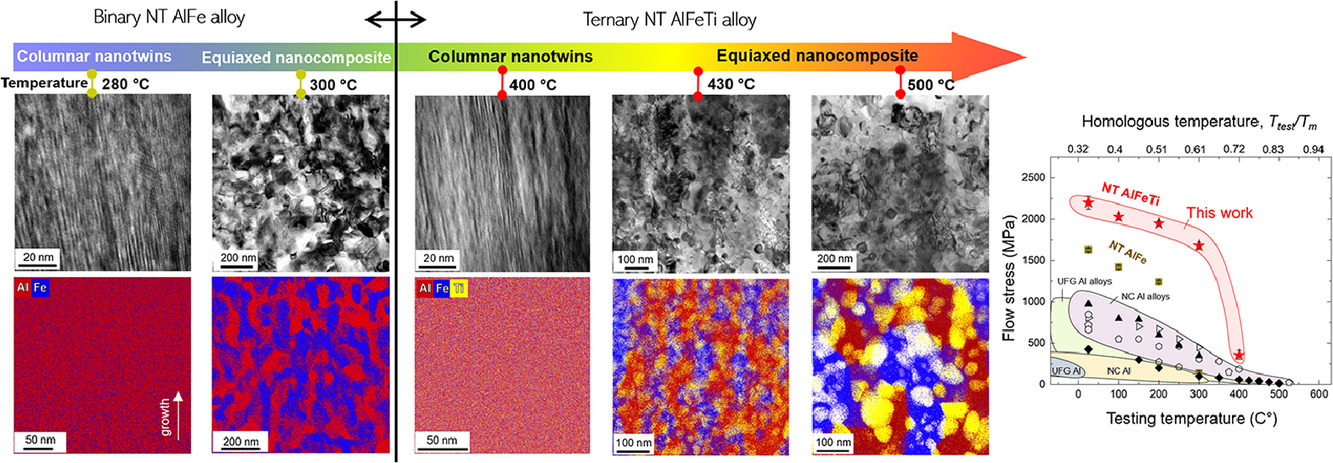

26. Coupled solute effects enable anomalous high-temperature strength and stability in nanotwinned Al alloys

耦合溶質效應使納米鋁合金具有反常的高溫強度和穩定性

Qiang Li?, Dongyue Xie, Zhongxia Shang, Xing Sun, Jaehun Cho,Yifan Zhang,Sichuang Xue,Haiyan Wang,JianWang,Xinghang Zhang?

Qiang Li:li2584@purdue.edu

Xinghang Zhang:xzhang98@purdue.edu

https://doi.org/10.1016/j.actamat.2020.08.059

摘要

納米析出物或晶粒細化可以有效地提高鋁合金的機械強度,但析出硬化和納米晶鋁合金的室溫強度往往低于1GPa。此外,在低于300°C時,納米析出強化或細晶強化的鋁合金很大程度上受到急劇機械軟化的影響,這主要是由于其顯微結構穩定性的降低。在這里,我們報道了納米Al-Fe-Ti合金中的耦合溶質效應機制,該機制使納米顆粒在400°C仍保持穩定,在300°C達到前所未有的~1.7 GPa的高溫流動應力。鋁中的過飽和的鐵溶質充當了有效的晶粒細化劑,形成超強固溶體合金。更重要的是,經驗證據結合第一性原理計算表明,鈦溶質延緩了鐵溶質的團聚,從而顯著地延長了納米鋁合金中納米顆粒穩定性的溫度窗口。這項研究提供了通過耦合溶質效應來為潛在高溫應用設計超強和穩定納米結構合金的思路。

英文摘要

Nanoprecipitates or grain refinement can effectively enhance the mechanical strength of Al alloys, but the room-temperature strengths of precipitation hardened and nanocrystalline Al alloys often fall below 1 GPa. Furthermore, they are largely plagued by precipitous mechanical softening at elevated temperature below 300°C, mostly due to degraded microstructural stability. Here, we report a mechanism of coupled solute effect in nanotwinned Al-Fe-Ti alloys that enables stability of nanograins up to 400°C and an unprecedented high-temperature flow stress of ~ 1.7 GPa at 300°C. The supersaturated Fe solutes in Al act as effective grain refiner, forming superstrong solid solution alloys. More importantly, empirical evidence combined with first principle calculations indicate that the Ti solutes delay the agglomeration of Fe solutes, thereby remarkably extending the temperature window for the stability of nanograins in nanotwinned Al alloys. This study highlights the opportunity to design ultrastrong and stable nanostructured alloys for potential high temperature applications via a coupled solute effect.

ACTA Vol. 200, Nov. 2020, P389-403

27. Phase boundary segregation-induced strengthening and discontinuous yielding in ultrafine-grained duplex medium-Mn steels

超細晶雙相中錳鋼的相邊界偏析強化和不連續屈服

Yan Ma?, Binhan Sun?, Alexander Schökel, Wenwen Song, Dirk Ponge,Dierk Raabe,Wolfgang Bleck

Yan Ma:y.ma@mpie.de

Binhan Sun:b.sun@mpie.de

https://doi.org/10.1016/j.actamat.2020.09.007

摘要

結合不同的相成分來實現機械復合效應從而獲得優異的強度-韌性協同效應,已經成為先進高強度鋼微觀組織設計的重要策略。在微觀結構中引入多相本質上產生了大量的相界,這種異質界面會影響材料的位錯活動和損傷形成等。然而,相界的特征,如化學修飾狀態,是否也會對多相鋼的力學行為產生影響仍然是一個問題。本文揭示了超細晶雙相中錳鋼的相界偏析強化效應。我們發現,鐵素體-奧氏體相界的碳偏析可以通過調整亞溫退火后的冷卻條件來控制,這種相界偏析使得屈服強度提高了100-120MPa,同時促進了不連續屈服。相界處的碳偏析阻礙了界面位錯的釋放,從而增加了激活位錯形核和引發塑性變形所需的應力。這表明,碳在相界的富集可以增強位錯擴散的能壘,為塑性流動雪崩和不連續屈服提供了有利條件。這些發現豐富了目前對中錳鋼屈服行為的理解,更重要的是,有助于利用和控制相界偏析來改善多相金屬材料的力學性能。

英文摘要

The combination of different phase constituents to realize a mechanical composite effect for superior strength-ductility synergy has become an important strategy in microstructure design in advanced high-strength steels. Introducing multiple phases in the microstructure essentially produces a large number of phase boundaries. Such hetero-interfaces affect the materials in various aspects such as dislocation activity and damage formation. However, it remains a question whether the characteristics of phase boundaries, such as their chemical decoration states, would also have an impact on the mechanical behavior in multiphase steels. Here we reveal a phase boundary segregation-induced strengthening effect in ultrafine-grained duplex medium-Mn steels. We found that the carbon segregation at ferrite-austenite phase boundaries can be manipulated by adjusting the cooling conditions after intercritical annealing. Such phase boundary segregation in the investigated steels resulted in a yield strength enhancement by 100–120 MPa and simultaneously promoted discontinuous yielding. The sharp carbon segregation at the phase boundaries impeded interfacial dislocation emission, thus increasing the stress required to activate such dislocation nucleation process and initiate plastic deformation. This observation suggests that the enrichment of carbon at the phase boundaries can enhance the energy barrier for dislocation emission, which provides a favorable condition for plastic flow avalanches and thus discontinuous yielding. These findings extend the current understanding of the yielding behavior in medium-Mn steels, and more importantly, shed light on utilizing and manipulating phase boundary segregation to improve the mechanical performance of multiphase metallic materials.

ACTA Vol. 200, Nov. 2020, P404-416

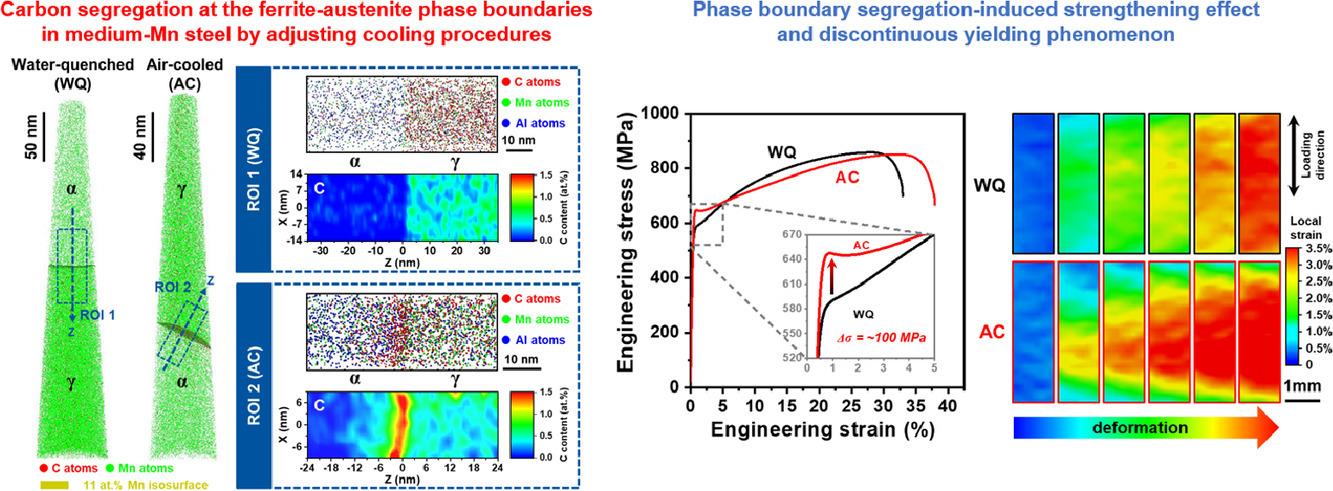

28. The role of crystallographic texture on mechanically induced grain boundary migration

晶體學織構對機械誘導晶界遷移的作用

O. Renk?, P. Ghosh, R.K. Sabat, J. Eckert, R. Pippan

O. Renk:oliver.renk@oeaw.ac.at

https://doi.org/10.1016/j.actamat.2020.08.071

摘要

應變誘導的晶界或三叉晶界遷移決定了經嚴重塑性變形后形成的納米晶的尺寸和形貌,進而影響材料的力學性能。大量研究表明,納米晶在形變過程中會發生長大。由于嚴重塑性變形后的納米結構是局部應力下晶粒細化與粗化動態平衡的結果,因此人們普遍認為,這種納米結構在進一步加載過程中將保持穩定。然而,我們發現,采用高壓扭轉法(HPT)制備的超細晶純銅在后續冷軋時,晶粒會發生明顯粗化,粗化過程一直持續到軋制應變ε=1,并最終形成軋制織構。繼續加大應變,我們觀測到晶粒再次細化,細化后的最小晶粒尺寸與HPT制備得到的超細晶相當。有趣的是,在HPT樣品的另外兩個方向,即TD和RD方向,則較少觀察到晶粒長大。以上結果表明,樣品織構取決于新加應變的大小和方向,因此晶粒取向對應變誘導粗化過程具有顯著影響。

英文摘要

Mechanically induced migration of grain boundaries and triple junctions not only determines the size and shape of nanostructures created by severe plastic deformation, it substantially affects their mechanical properties as well. Grain growth during deformation of nanostructures has been widely observed. As the nanostructures processed by severe plastic deformation are a consequence of a dynamic equilibrium between refinement and local mechanically induced coarsening, it is widely accepted that such nanostructures would remain stable upon further loading. However, pronounced grain coarsening can be observed when pure UFG copper prepared by high pressure torsion (HPT) is additionally cold rolled. The coarsening continues up to rolling strains, ε = 1, i.e. until favourable grain orientations for rolling are developed. For larger strains subsequent refinement to minimum boundary spacing identical to the HPT microstructure is observed. Interestingly, less grain growth is observed for two other sample orientations of the HPT microstructure which are rolled along different directions with respect to the sample coordinate frame. Crystallographic texture of these samples were favourable with respect to the new strain path, highlighting its role for mechanically induced growth and suggesting a distinct influence of grain orientation on the mechanically induced coarsening process.

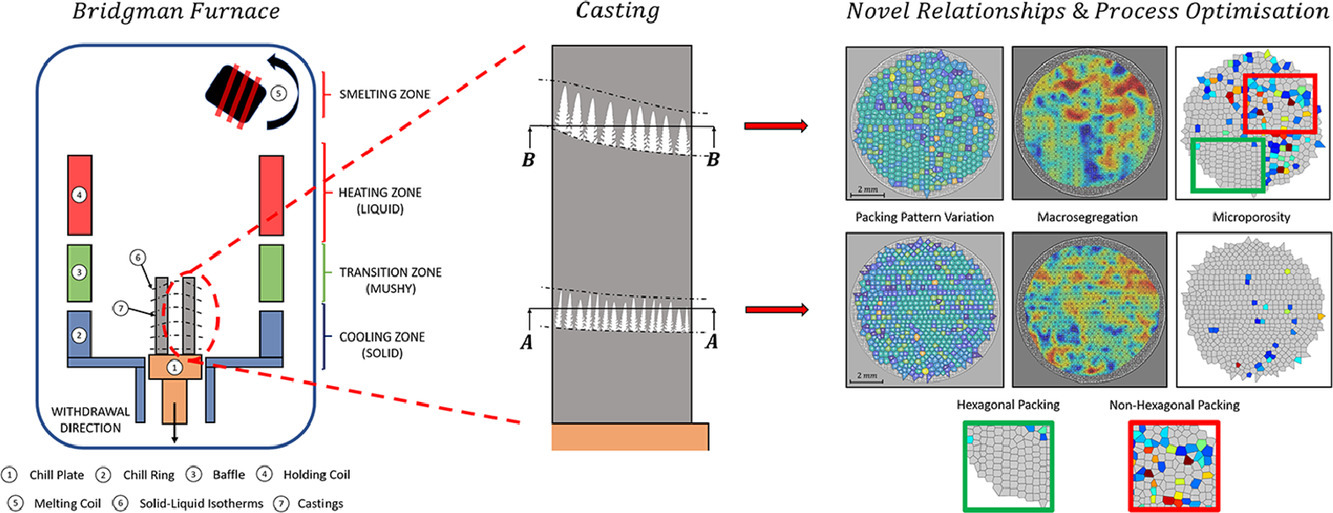

ACTA Vol. 200, Nov. 2020, P417-431

29. On the nature of hexagonality within the solidification structure of single crystal alloys: Mechanisms and applications

關于單晶合金凝固組織中六邊形的性質:機理和應用

Joel Strickland, Bogdan Nenchev, Samuel Perry, Karl Tassenberg, Simon Gill,Chinnapat Panwisawas,Hongbiao Dong?,Neil D'Souza,Steve Irwin

Hongbiao Dong:h.dong@le.ac.uk

https://doi.org/10.1016/j.actamat.2020.09.019

摘要

一次間距是單晶合金凝固過程中的一個重要現象。它決定了微觀偏析、缺陷形成、凝固組織固溶所需的時間,以及單晶組件的最終性能。提出了一種新的體視學表征算法:形狀受限的一次間距(SLPS),并應用于研究在不同鑄造條件下凝固的單晶合金中胞狀和樹枝狀堆垛的形成。結果表明,在穩態條件下,單晶有形成六方堆垛的趨勢,而其他堆垛方式都是亞穩態。利用SLPS算法,證明了堆垛的形成和局部一次間距與針尖生長動力學有關。此外,確認了定向凝固過程中的彎曲等溫線的作用。等溫線曲率導致非均勻熔體成分梯度平行于固液界面,從而在顯微組織內形成亞穩態堆垛、小角度晶界和孔隙率。

英文摘要

Primary spacing is a key phenomenon during solidification of single crystal alloys. It determines microsegregation, defect formation, the time required to solutionise the solidified structure, and the final performance of single crystal components. A novel stereological characterisation algorithm: Shape-Limited Primary Spacing (SLPS) is developed and applied to study the formation of cellular and dendritic packing patterns in single crystal alloys solidified under different casting conditions. The results reveal the tendency for single crystals to form hexagonally packed structures under steady state conditions, while all other packing arrangements constitute a metastable state. Using the SLPS algorithm, it has been demonstrated that packing pattern formation and local primary spacing can be related to tip growth kinetics. Further, the role of curved isotherms that occur in directional solidification has been identified. Isotherm curvature results in non-uniform liquid compositional gradients developing parallel to a growing solid interface, leading to the formation of metastable packing, low-angle grain boundaries, and porosity formation within the microstructure.

ACTA Vol. 200, Nov. 2020, P432-441

30. Wear-induced microstructural evolution of nanocrystalline aluminum and the role of zirconium dopants

納米鋁的磨損誘導組織演變及鋯摻雜的作用

Yeqi Shi, Izabela Szlufarska?

Izabela Szlufarska:izabela@engr.wisc.edu

https://doi.org/10.1016/j.actamat.2020.09.005

摘要

通過分子動力學模擬研究了納米晶鋁的摩擦磨損特性,并考慮了摻雜劑的影響。結果表明,Zr摻雜的NC-Al合金具有較好的耐磨性和較小的摩擦力,這與Zr摻雜樣品具有較高的硬度和較高的強度相一致。其機制是抑制晶界位錯的發展以及晶界的遷移與滑移。經過多次滑動循環后,機械響應的趨勢發生逆轉,純NC-Al比摻雜樣品表現出更好的耐磨性和更低的摩擦力。其中一個原因是,在磨損過程中引入較高的位錯密度,導致了更多的應變硬化;另一個原因是純NC-Al比摻雜樣品經歷了更顯著的晶粒長大。由于我們的樣品的晶粒尺寸處于反Hall-Petch區域,這里晶粒長大導致純樣品的強化。分析和討論了純NC-Al晶粒長大的機理及其對摻雜NC-Al晶粒生長的抑制作用。

英文摘要

Wear and friction of nanocrystalline (NC) aluminum were investigated via molecular dynamics simulations and the effects of dopants were considered. Zr-doped NC Al was found to have a better wear resistance and a smaller friction force, which is consistent with a higher hardness and a higher strength of the doped sample. The underlying mechanisms are suppressed emission of dislocations from grain boundaries (GBs), suppressed GB migration, and suppressed GB sliding. After multiple sliding cycles, the trend in mechanical response was reversed, with the pure NC Al showing a better wear resistance and a lower friction force than the doped sample. One reason is that the higher dislocation density introduced during wear into the pure sample leads to more strain hardening. Another reason is that the pure NC Al has undergone more significant grain growth than the doped sample. Since the grain size of our samples is in the inverse Hall-Petch regime, here grain growth leads to strengthening of the pure sample. Mechanisms of grain growth in the pure NC Al and its suppression in the doped NC Al are analyzed and discussed.

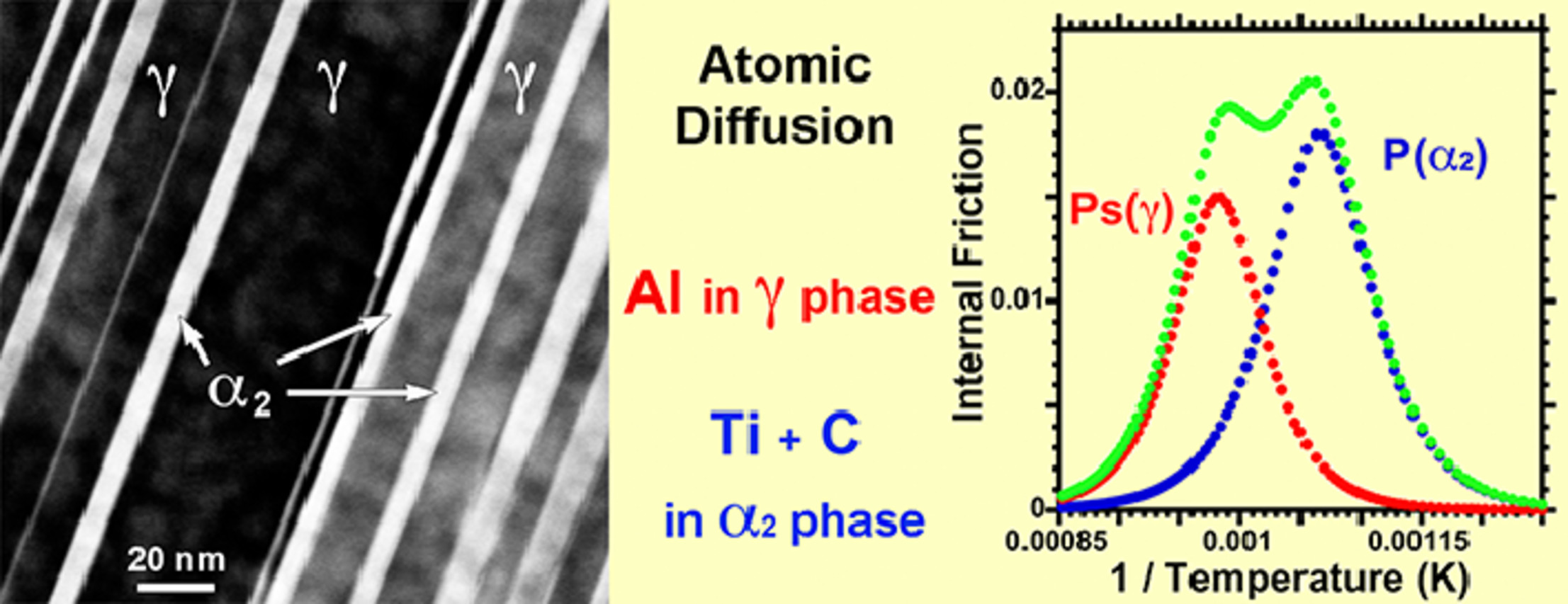

ACTA Vol. 200, Nov. 2020, P442-454

31. High-temperature phenomena in an advanced intermetallic nano-lamellar γ-TiAl-based alloy. Part I: Internal friction and atomic relaxation processes

先進的金屬間化合物納米層狀γ-TiAl基合金的高溫現象。第一部分:內耗和原子弛豫過程

Leire Usategui, Thomas Klein, María L. Nó, Svea Mayer, Helmut Clemens,Jose M. San Juan?

M. San Juan:jose.sanjuan@ehu.es

https://doi.org/10.1016/j.actamat.2020.09.025

摘要

金屬間化合物γ-TiAl基合金在航空發動機低壓渦輪和汽車發動機渦輪增壓器上都有應用。然而,這些輕質合金仍然需要通過微合金化和微觀結構的調整來提高其抗蠕變性能,從而提高其最高工作溫度。本文研究了摻雜少量C和Si的全納米層狀先進γ-TiAl基合金,以期對高溫下的原子遷移機制有更深入的了解,從而控制蠕變性能。這項研究是通過1223 K的內耗測量進行的。我們證明C對α2相中的Ti擴散有顯著的影響,導致Ti擴散的活化能增加,其值大概為ΔETi(α2)=0.32 eV/at%C。本文提出了一個能解釋這一點的弛豫過程的原子模型現象。在這種納米層狀TiAl合金中觀察到了一個額外的內耗峰,至今仍被高溫背景所掩蓋,并對內耗譜進行了仔細的去卷積分析。這一新的弛豫過程是由于Al原子在γ-TiAl晶格中的短距離擴散,其激活能為3.70ev。為解釋這種弛豫現象,提出了一種應力誘導晶格重取向的新概念。最后,提出了一種分析與蠕變行為密切相關的高溫內耗背景的實驗方法,用來研究γ-TiAl基合金在高溫背景下具有最高的激活能的全納米層狀組織。

英文摘要

Intermetallic γ-TiAl based alloys have found applications in the low-pressure turbine of aircraft engines as well as in the turbocharger unit of automotive engines. However, these light-weight alloys must still be improved, through micro-alloying and tailoring the microstructure, to increase their creep resistance and consequently their maximum working temperature. In this work, a fully nano-lamellar advanced γ-TiAl based alloy doped with small amounts of C and Si is investigated in order to gain a deeper understanding of the atomic mobility mechanisms taking place at high temperature, thus controlling the creep properties. The study was approached through internal friction measurements up to 1223 K. We demonstrate that C has a notable influence on Ti diffusion in α2 phase, leading to an increase of the activation energy for Ti diffusion, which is assessed at ΔETi(α2)=0.32 eV per at% C. An atomic model for the relaxation process is proposed capable to explain this phenomenon. An additional internal friction peak, which, up to now, remained hidden by the high temperature background, was observed in this nano-lamellar TiAl alloy and analyzed through a careful de-convolution of the internal friction spectra. This new relaxation process, with activation energy of 3.70 eV, is attributed to the short distance diffusion of Al atoms in the γ-TiAl lattice. A novel concept of stress-induced cell-lattice reorientation is proposed to explain this relaxation. Finally, a new experimental method to analyze the high temperature internal friction background, which is closely related to the creep behavior, was developed to study the fully nano-lamellar microstructure, whose high temperature background exhibits the highest activation energy ever measured in a γ-TiAl based alloy.

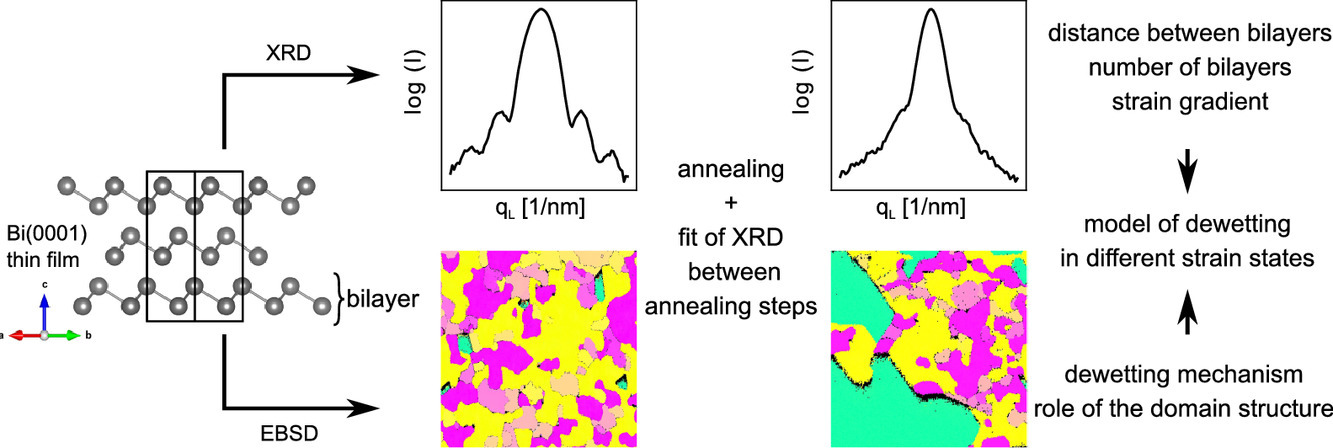

ACTA Vol. 200, Nov. 2020, P455-462

32. Atomistic view onto solid state dewetting: Thin bismuth films with and without strain gradient

固態去濕的原子論觀點:有應變梯度和無應變梯度的鉍薄膜

Constantin Wansorra, Enrico Bruder, Wolfgang Donner

ConstantinWansorra:constantin.wansorra@tu-darmstadt.de

https://doi.org/10.1016/j.actamat.2020.09.030

摘要

本文以硅基外延鉍薄膜為模型系統,對固態去濕進行了詳細的研究。利用衍射和成像兩種方法,通過分析x射線衍射晶體截斷棒來確定原子參數,如晶胞覆蓋率、晶格間距及其梯度。揭示了有應變梯度和無應變梯度試樣的不同去濕行為。此外,我們還討論了阻礙應變梯度影響的可能原因,例如界面能降低或臺階邊緣擴散勢壘增加,我們使用Johnson-Mehl-Avrami-Kolmogorov模型對其進行量化,并提出了鉍的臺階邊緣自擴散模型。

英文摘要

We present a detailed study of solid state dewetting choosing epitaxial bismuth films on silicon as a model system. Exploiting both diffraction and imaging methods, we determine atomistic parameters like unit cell coverage, lattice spacings and gradients thereof through the analysis of x-ray diffraction crystal truncation rods. A different dewetting behavior of samples with and without strain gradient is revealed. Additionally, we discuss possible reasons for the impeding influence of a strain gradient, such as a reduced interface energy or increased step edge diffusion energy barrier, which we quantify by using a Johnson-Mehl-Avrami-Kolmogorov model. A model for the step edge self diffusion of Bismuth is presented.

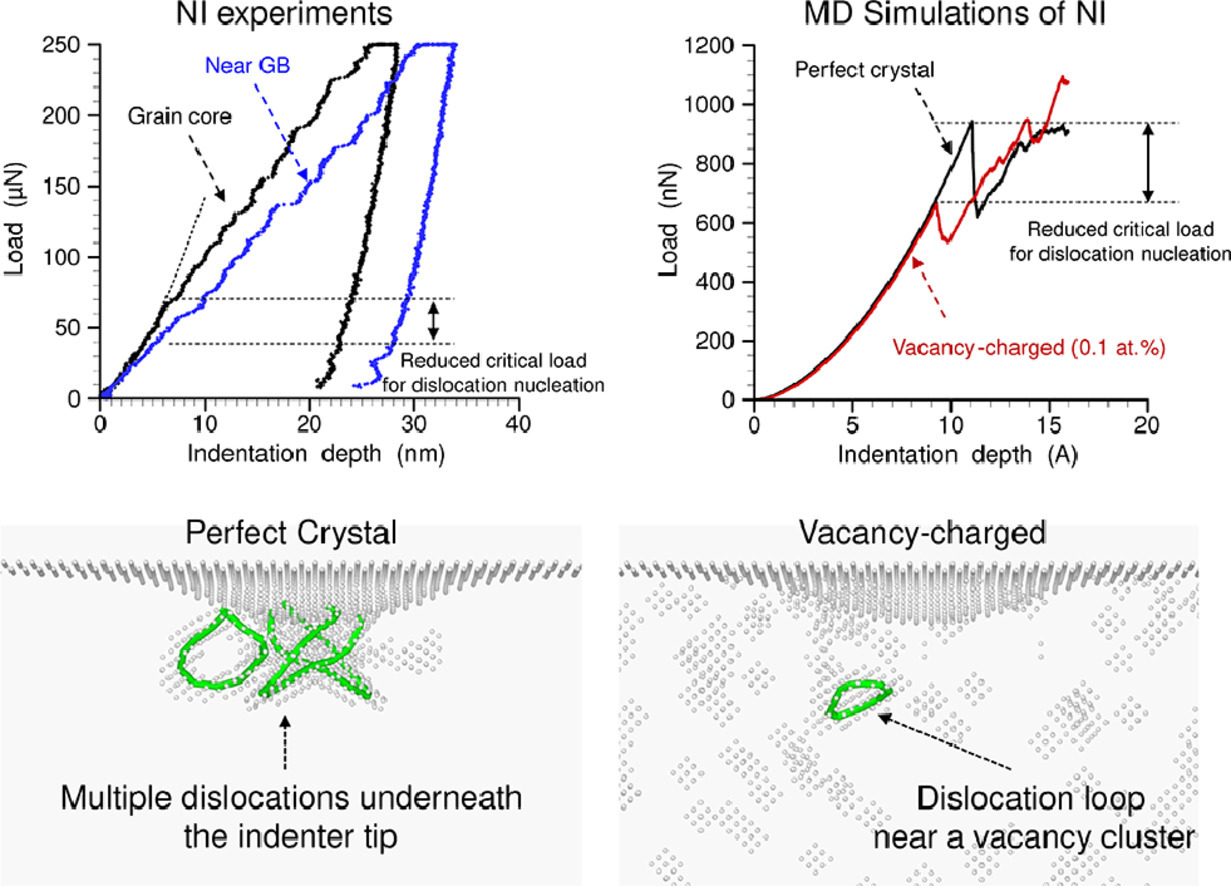

ACTA Vol. 200, Nov. 2020, P471-480

33. Mechanical degradation due to vacancies produced by grain boundary corrosion of steel

鋼鐵材料中因晶界腐蝕產生空位導致的機械性能劣化

Denizhan Yavas, Thanh Phan, Liming Xiong, Kurt R. Hebert, Ashraf F. Bastawros?

A.F. Bastawros:bastaw@iastate.edu

https://doi.org/10.1016/j.actamat.2020.08.080

摘要

韌性合金在腐蝕環境中往往因機械和化學相互作用導致晶間應力腐蝕開裂,而我們對這一過程的理解還遠遠不夠。本文中,我們研究了無氫高應力腐蝕條件下,低合金管線鋼中的缺陷形成和力學性能劣化。納米壓痕實驗表明,被腐蝕的晶界附近發生了局部軟化,位錯形核臨界載荷顯著降低。分子動力學模擬表明金屬空位和非間隙氫原子是導致這種現象的主要原因。富空位樣品的位錯激活體積和激活能僅約富氫樣品的一半。與材料中的空位濃度與硅原子濃度相當,這與納米壓痕結果取得了定量上的一致,表明空位起源于晶界處硅溶質原子的氧化。以上研究結果有助于我們加深對非清脆環境下可能引起晶界劣化的空位缺陷形成機制的理解。

英文摘要

Ductile alloys fail in corrosive environments by intergranular stress corrosion cracking, through interactions between mechanical and chemical processes that are not yet understood. We investigate formation and mechanical effects of metal defects produced by grain boundary corrosion of low-alloy pipeline steel, at conditions of high susceptibility to stress corrosion cracking in the absence of hydrogen evolution. Nanoindentation measurements show local softening near corroded grain boundaries, indicated by significantly reduced critical loads for dislocation nucleation. Molecular dynamics simulations of nanoindentation of bulk iron showed that metal vacancies and not interstitial hydrogen atoms explain the observed critical load reduction. Both the dislocation activation volume and dislocation activation energy for vacancy-charged samples are found to be nearly one-half of that for a hydrogen charged samples. Quantitative agreement with experimentally measured indentation response was found for vacancy concentrations equivalent to the bulk silicon concentration in the steel, suggesting that vacancies originate from oxidation of reactive silicon solute atoms at grain boundaries. The results help explain the chemical mechanism of formation of vacancy defects that may participate in grain boundary degradation in the absence of hydrogen embrittlement environment.

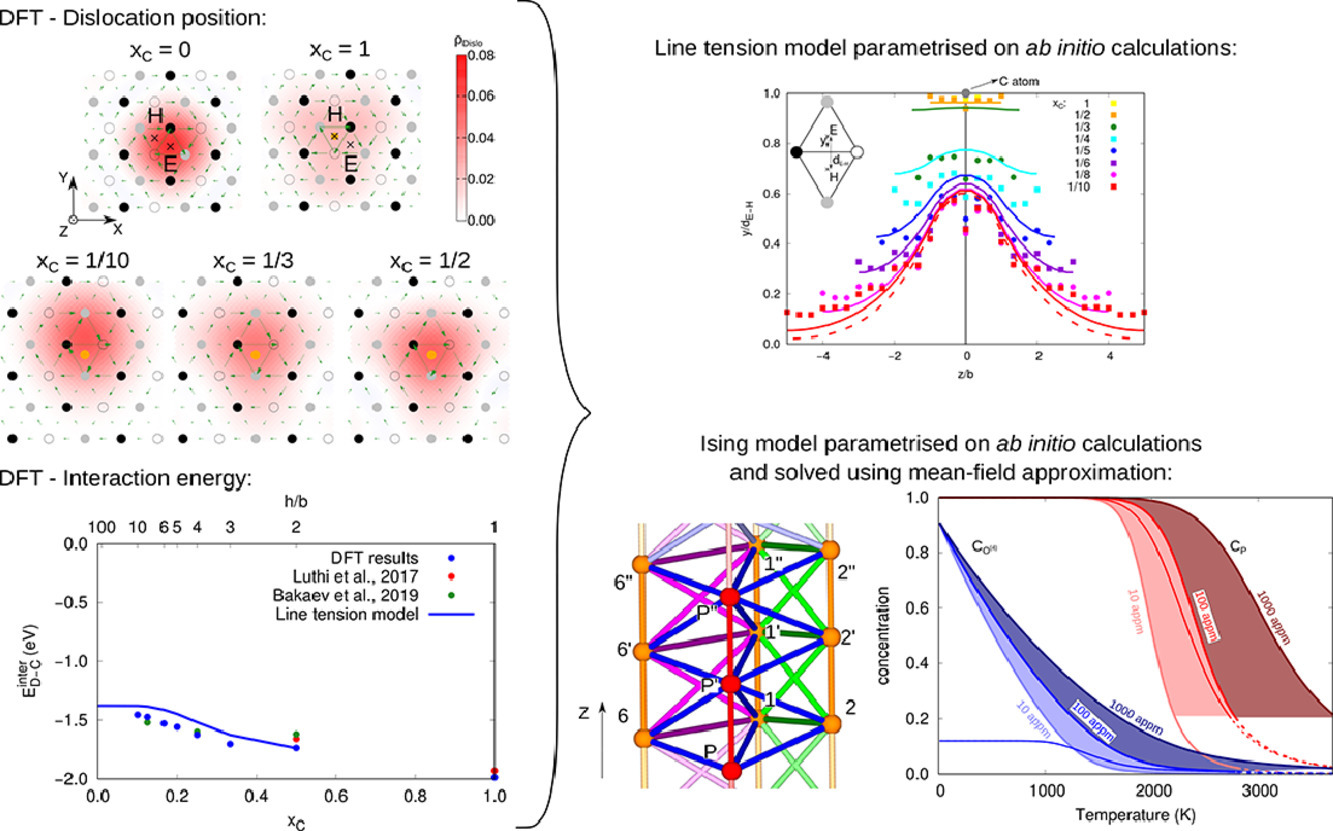

ACTA Vol. 200, Nov. 2020, P481-489

34. Screw dislocation-carbon interaction in BCC tungsten: an ab initio study

BCC鎢合金中螺位錯與碳相互作用的第一性原理模擬計算

Guillaume Hachet?, Lisa Ventelon, François Willaime, Emmanuel Clouet?

G. Hachet:guillaume.hachet@cea.fr

E. Clouet:emmanuel.clouet@cea.fr

https://doi.org/10.1016/j.actamat.2020.09.014

摘要

我們使用了第一性原理計算研究了鎢合金中的碳與螺旋位錯的相互作用。研究表明,位錯附近的碳原子誘發位錯重構,位錯松弛形成硬核結構,而這種結構在純鎢中并不穩定。這種重構是由于碳容易在位錯線發生偏聚,因此與位錯柱面具有較強的結合能。然而,這種重構是不完全的,位錯傾向于回到其基態。這種碳原子釘扎位錯的不穩定狀態可以用一個簡單的線張力模型進行描述。當溶質位于離重構核心第四近的八面體位置時,在較遠距離上也能觀測到較大的碳-位錯引力。我們使用了Ising模型和平均場近似對碳在不同偏聚位置的平衡濃度進行了模擬。結果表明,螺位錯處于碳原子飽和狀態,并被釘扎在其核結構中,這種情況最高可持續至2500 K。

英文摘要

The interaction between carbon and screw dislocations in tungsten is investigated using ab initio calculations. The presence of carbon atoms in the vicinity of the dislocation induces a reconstruction, with the dislocation relaxing to a configuration, the hard core structure, which is unstable in pure tungsten. The reconstruction corresponds to a strong binding of carbon in the prismatic sites created by the dislocation which is perfect for high concentrations of carbon segregated on the dislocation line. However, the reconstruction is only partial for lower atomic fractions, with the dislocation tending to fall back in its easy core ground state. This pinning by carbon atoms of the dislocation in an unstable position is well described by a simple line tension model. A strong carbon-dislocation attraction is also evidenced at larger separation distances, when the solute is in the fourth nearest neighbour octahedral sites of the reconstructed core. The equilibrium concentrations of carbon in these different segregation sites are modelled with an Ising model and using a mean-field approximation. This thermodynamic model evidences that screw dislocations remain fully saturated by carbon atoms and pinned in their hard core configuration up to about 2500 K.

ACTA Vol. 200, Nov. 2020, P510-525

35. Critical nuclei at hetero-phase interfaces

異質界面的臨界形核

Rongpei Shi?, Tae Wook Heo?, Brandon C. Wood, Yunzhi Wang?

R. Shi:shi7@llnl.gov

T.W. Heo:heo1@llnl.gov

Y. Wang:wang.363@osu.edu

https://doi.org/10.1016/j.actamat.2020.09.012

摘要

兩步形核,即以亞穩中間相作為熱力學穩定相形核的前驅體,是一種在固態相變中被廣泛觀察到的實驗現象。其優點之一是穩定相可以在原相與前驅相之間的異相界面上非均勻形核。雖然晶界和惰性表面的非均相形核理論已經建立起來,但我們對反應性相界面處的非均勻形核理解仍有欠缺。在相界面處化學驅動力不連續性,顯著地影響了形核的基本性質,而現有模型都無法很好地模擬和解釋這種影響。本文中,我們基于這些影響,對經典形核理論在異相界面的應用進行了括展。我們的模型表明,沿最小能量路徑形成的核心形狀與尺寸高度相關,而這種附加自由度導致臨界核體積和活化能相比傳統預測低了幾個數量級。基于模擬結果,我們建立了以界面能和體驅動力之比為參數的靈敏度圖,對不同模型預測的形核勢壘的差異進行了量化。

英文摘要

Two-step nucleation, in which a metastable intermediate phase acts as a precursor for nucleating a thermodynamically stable phase, has been widely observed in many materials systems and solid-state reactions. Among the advantages of two-step nucleation is that the stable phase may nucleate heterogeneously at the hetero-phase interface between the original and the precursory phases. Although heterogeneous nucleation (HN) theories for homo-phase grain boundaries and inert surfaces are well established, our understanding of HN at reactive hetero-phase interfaces remains incomplete. This deficiency stems from the discontinuity of the chemical potential driving force across the hetero-phase interface, which profoundly affects the fundamental properties of the nucleus in a way that is not properly accounted for in existing models. Herein, we incorporate these effects to extend the classical nucleation theory to HN at hetero-phase interfaces. Our extended model demonstrates that the nucleus shape along the minimum energy path is strongly size-dependent, and this additional degree of freedom can result in the reduction of the critical nucleus volume and associated activation energy barrier by orders of magnitude relative to conventional predictions. The simulation results are used to construct a sensitivity map in the parameter space of interfacial energy and bulk driving force ratios, which quantifies the difference in nucleation barriers predicted by different models.

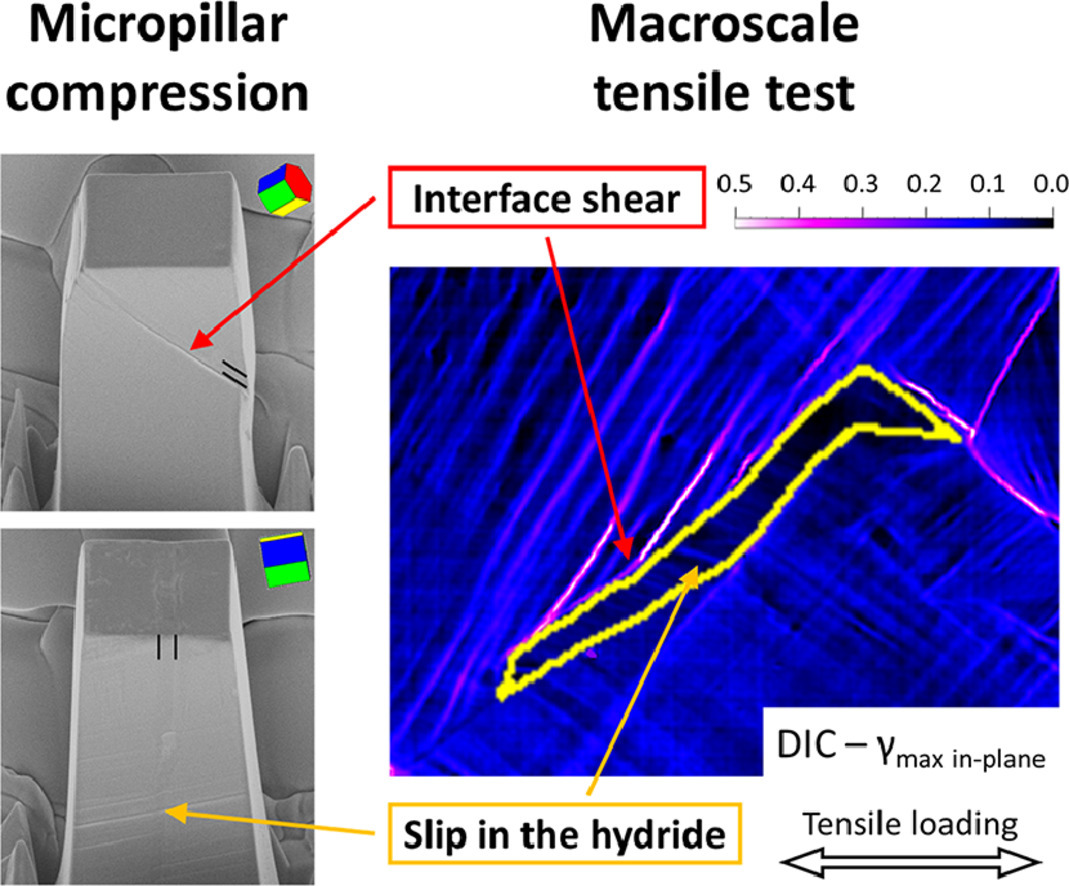

ACTA Vol. 200, Nov. 2020, P537-550

36. Slip–hydride interactions in Zircaloy-4: Multiscale mechanical testing and characterisation

Zircaloy-4鋯合金中滑移和氫化物相互作用的多尺度力學測試和表征

Siyang Wang?, Finn Giuliani, T. Ben Britton

S. Wang:siyang.wang15@imperial.ac.uk

https://doi.org/10.1016/j.actamat.2020.09.038

摘要

我們通過單晶樣品的原位SEM微柱壓縮試驗和多晶樣品的DIC宏觀拉伸試驗,研究了負載條件下Zircaloy-4鋯合金中δ氫化物和塑性滑移之間的相互作用。氫化物在基面附近有取向。對于取向為<a>基面滑移的微柱,由于所需剪應力較低,因此氫化物-基體界面發生局部剪切的優先度高度α-Zr基體的滑移。而對于取向為<a>棱柱面滑移的微柱,氫化物中發生塑性滑移所需的剪切應力則略高于<a>棱柱面滑移系的臨界剪切應力(CRSS)。在這種情況下,氫化物的滑移可能通過<110>型切變實現,該切變平行于基體中的<a>型切變。我們把以上結果應用在了宏觀多晶樣品的高分辨DIC實驗的結果分析中。我們發現,局部的界面切變仍然是一個重要的變形路徑,并且它與相界面附近的基體滑移相互耦合。在與相鄰氫化物-基體界面近似垂直的平面上發生的基體滑移既可能導致氫化物內部的塑性滑移,也可能因在界面處受阻而導致應力集中。通過這些機制,在塑性階段初期,氫化物的存在導致了Zircaloy-4 鋯合金表現出顯著的應變集中。

英文摘要

The interactions between δ-hydrides and plastic slip in a commercial zirconium alloy, Zircaloy-4, under load were studied using in situ secondary electron microscope (SEM) micropillar compression tests of single crystal samples and ex situ digital image correlation (DIC) macroscale tensile tests of polycrystalline samples. The hydrides decorate near basal planes in orientation, and for micropillars orientated for <a> basal slip localised shear at the hydride–matrix interface is favoured over slip in α-Zr matrix due to a lower shear stress required. In contrast, for pillars oriented for <a> prismatic slip the shear stress needed to trigger plastic slip within the hydride is slightly higher than the critical resolved shear stress (CRSS) for the <a> prismatic slip system. In this case, slip in the hydride is likely achieved through <110>-type shear which is parallel to the activated <a>-type shear in the parent matrix. At a longer lengthscale, these results are used to inform polycrystalline samples analysed using high spatial resolution DIC. Here localised interface shear remains to be a significant deformation path which can both cause and be caused by matrix slip on planes closely-oriented to the phase boundaries. Matrix slip on planes nearly perpendicular to the adjacent hydride–matrix interfaces can either result in plastic slip within the hydrides or get arrested at the interfaces, generating local stress concentration. Through these mechanisms, the presence of δ-hydrides leads to enhanced strain localisation in Zircaloy-4 early in the plastic regime.

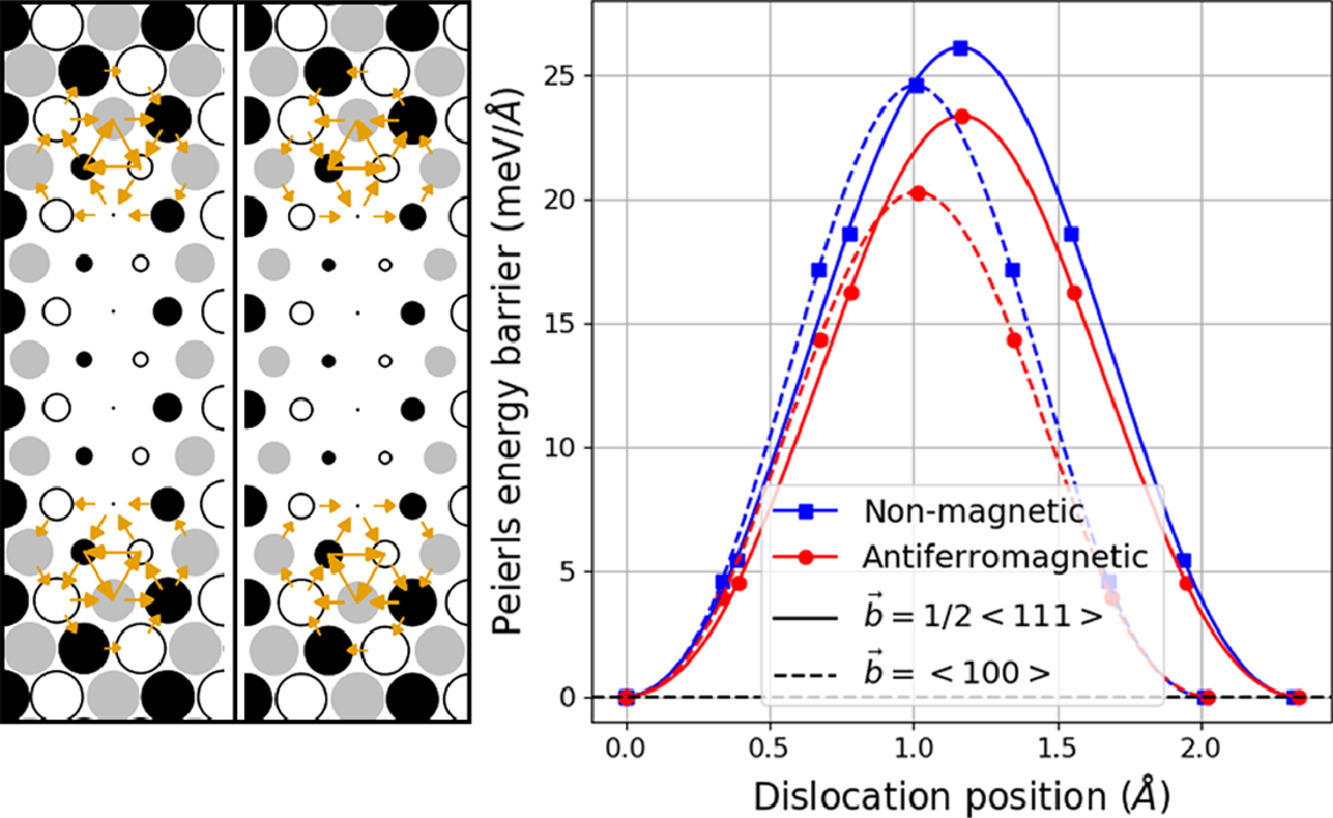

ACTA Vol. 200, Nov. 2020, P570-580

37. Impact of magnetism on screw dislocations in body-centered cubic chromium

磁場對體心立方鉻螺位錯的影響

Baptiste Bienvenu, Chu Chun Fu, Emmanuel Clouet?

E. Clouet:emmanuel.clouet@cea.fr

https://doi.org/10.1016/j.actamat.2020.09.041

摘要

我們采用第一性原理計算研究了磁場對體心立方鉻中螺位錯的影響。我們考慮了具有1/2 <111>和<100>伯氏矢量的螺位錯,并通過實驗對這兩個滑移系統的進行了觀測。在低溫下,鉻在<100>方向上近似具有反鐵磁特性,而1/2<111>不是一個周期性矢量。因此,伯氏矢量1/2 <111>的位錯在晶體發生剪切形變時將產生磁障,約束它們共存并成對移動,導致<111>超位錯的產生。另一方面,<100>是鉻磁序的周期性矢量,因此當<100>位錯滑移時,不產生磁障。為了方便比較,我們在鉻的磁性和非磁性相中對位錯性質進行了計算,發現磁性對兩個滑移系統的結構和能量影響較小。對于1/2 <111> {110}和<100> {110}滑移體系,阻礙位錯在{110}平面上滑移的Peierls能壘大體相當,其中磁有序相中的Peierls應力略低一點。

英文摘要

The influence of magnetism on the properties of screw dislocations in body-centered cubic chromium is investigated by means of ab initio calculations. Screw dislocations having Burgers vectors 1/2 <111> and <100> are considered, following experimental observations showing activity for both slip systems. At low temperature, chromium has a magnetic order close to antiferromagnetism along <100> directions, for which 1/2<111> is not a periodicity vector. Hence, dislocations with Burgers vectors 1/2 <111> generate magnetic faults when shearing the crystal, which constrain them to coexist and move pairwise, leading to dissociated <111> super-dislocations. On the other side, <100> is a periodicity vector of the magnetic order of chromium, and no such magnetic fault are generated when <100> dislocations glide. Dislocation properties are computed in the magnetically ordered and non magnetic phases of chromium for comparison purposes. We report a marginal impact of magnetism on the structural properties and energies of dislocations for both slip systems. The Peierls energy barrier opposing dislocation glide in {110} planes is comparable for both 1/2 <111> {110} and <100> {110} slip systems, with lower Peierls stresses in the magnetically ordered phase of chromium.

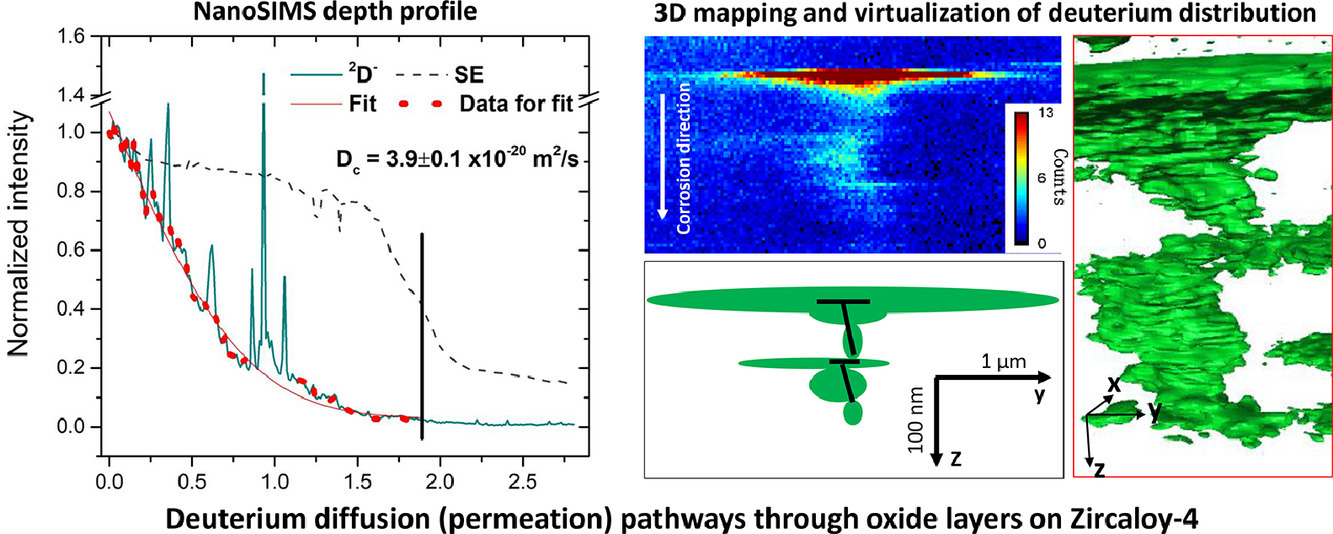

ACTA Vol. 200, Nov. 2020, P581-596

38. Characterisation of deuterium distributions in corroded zirconium alloys using high-resolution SIMS imaging

經腐蝕后鋯合金中氘分布的高分辨SIMS表征

Junliang Liu, Kexue Li?, James Sayers, Thomas Aarholt, Guanze He, Helen Hulme, Alistair Garner, Michael Preuss, Heidi Nordin, Jonna M. Partezana, Magnus Limbäck, Sergio Lozano-Perez, Susan Ortner, Chris R.M. Grovenor

K. Li:kexue.li@manchester.ac.uk

https://doi.org/10.1016/j.actamat.2020.09.040

摘要

氫通過Zr合金腐蝕形成的氧化物進行的擴散過程對氫吸附(HPU)速率有重要作用,氫的吸附會導致燃料包層的脆化,并限制核燃料的燃燒。繪制氫/氘在氧化層,特別是在近金屬/氧化物界面附近的分布,對理解氧化和氫吸附機制非常有價值。本研究中,我們通過高分辨SIMS對一系列Zr合金的氧化層中的氘分布進行了分析,包括經氧化的鋯-4、 Zr- 1Nb和Zr-2.5 Nb合金,以及經腐蝕的Zr-2.5 合金。與含Nb樣品相比,鋯-4樣品氧化物中的氘捕獲率和擴散系數更高。中子輻照提高了Zr-2.5 Nb樣品中氘的擴散系數、氧化層氘濃度和吸附率。SIMS和EDX/SEM分析表明,在所有試驗合金中,氘都沒有優先被吸附至氧化物中的第二相顆粒中,但有直接證據表明氘被吸附在氧化形成的微裂紋表面,且在鋯-4尤為明顯。以上結果在三維層面提供了獨特的氫吸收機制信息,并表明氧化物中相互聯通的孔隙可能控制水冷核反應堆中鋯合金氫吸附速率的關鍵。

英文摘要

Hydrogen diffusion through the oxide grown on Zr alloys by aqueous corrosion processes plays a critical role in determining the rate of hydrogen pickup (HPU) which can result in embrittlement of fuel cladding and limit the burnup of the nuclear fuel it encapsulates. Mapping the hydrogen/deuterium distributions in these oxide layers, especially in the barrier layer close to the metal/oxide interface, is a powerful way to understand the mechanism of both oxidation and hydrogen pickup. Here we have characterised by high-resolution SIMS analysis the deuterium distribution in oxide layers on a series of Zr alloys, including autoclave-oxidised Zircaloy-4, Zr-1Nb and Zr-2.5Nb alloys, and in-flux and out-of-flux corroded Zr-2.5Nb samples. Pre-transition Zircaloy-4 samples show a high deuterium trapping ratio in the oxide and a higher diffusion coefficient than in oxides on the Nb-containing samples. Neutron irradiation increases the deuterium diffusion coefficient, the deuterium concentration in the oxide and the pickup fraction in Zr-2.5 Nb samples. Comparative NanoSIMS and EDX/SEM analysis demonstrates that the deuterium is not preferentially trapped at second phase particles in the oxides on any of the alloys studied, but there is direct evidence for trapping at the surfaces of small oxide cracks especially in Zircaloy-4 samples. The high resolution mapping of these hot-spots in 3D can provide unique information on the mechanisms of hydrogen uptake, and suggests that the development of interconnected porosity in the oxide may be the critical rate-determining mechanism that controls HPU in the aqueous corrosion of zirconium alloys in water-cooled reactors.

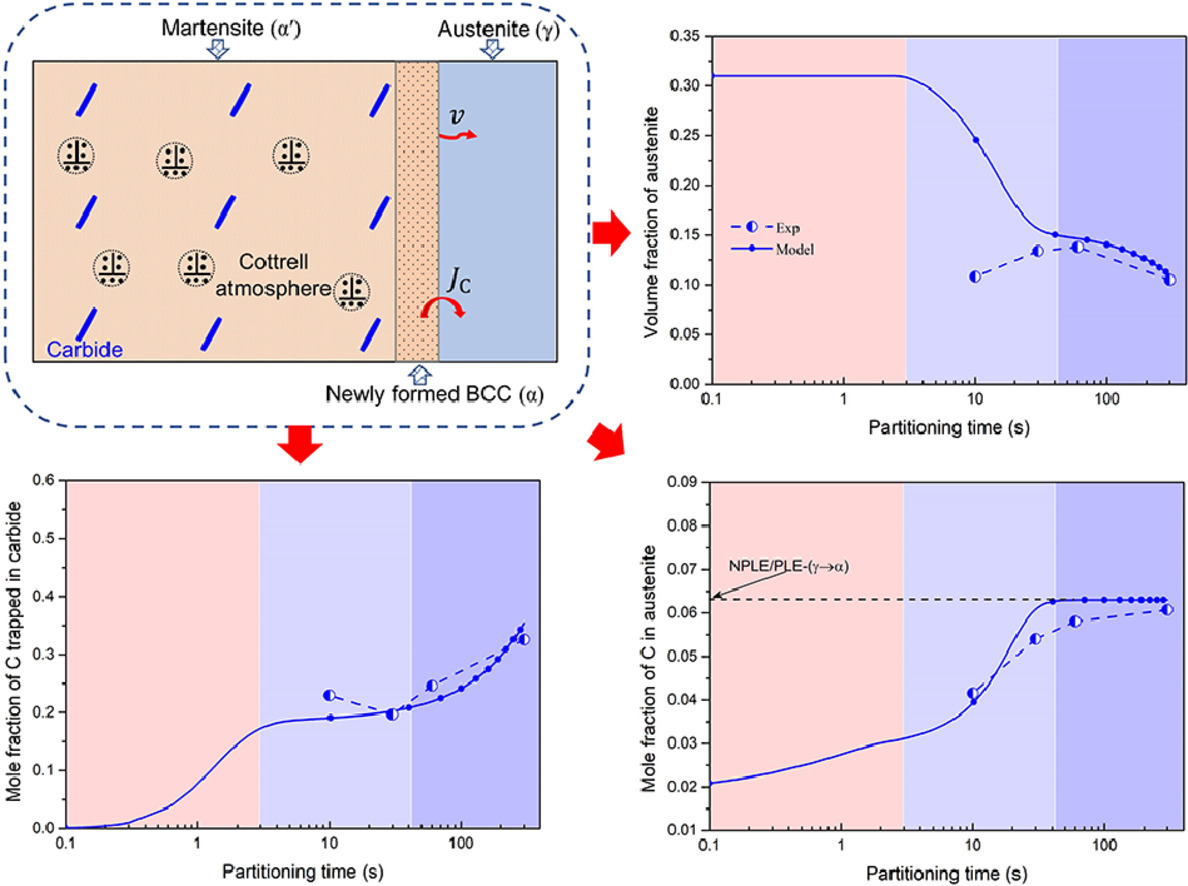

ACTA Vol. 200, Nov. 2020, P597-607

39. Incomplete carbon partitioning during quenching and partitioning of Fe–C–Mn–Si steels: Modeling and experimental validations

Fe–C–Mn–Si鋼淬火-配分過程中不完全碳配分現象的模擬和實驗驗證

Zongbiao Dai, Zhigang Yang, Chi Zhang, Hao Chen?

H. Chen:hao.chen@mail.tsinghua.edu.cn,清華大學

https://doi.org/10.1016/j.actamat.2020.09.045

摘要

在先進高強度鋼的淬火-配分(Q&P)工藝過程中,碳向位錯的偏聚和析出導致的碳消耗會顯著降低其向奧氏體的配分(即不完全配分現象),從而影響亞穩奧氏體的動力學、體積分數和穩定性。本研究中,我們建立了一個集成模型以闡明Fe-C-Mn-Si低合金鋼中的碳不完全配分機理,并量化不完全配分對奧氏體穩定性的影響。我們使用了半經驗方程來描述位錯附近柯氏氣團所消耗的碳分數。隨后,結合了Deschamps-Brechet模型和QP-LE模型對Q&P過程中碳化物的析出、碳配分和奧氏體分解之間的動力學競爭進行了模擬。研究發現,馬氏體中過渡碳化物的析出與碳向奧氏體的分配在Q&P過程早期相互耦合的,并在隨后促進了奧氏體的分解。通過考慮碳不完全配分和奧氏體分解的協同作用,該模型能夠較好預測配分過程中奧氏體體積分數及其含碳量的變化。

英文摘要

Carbon trapping at dislocations and carbide precipitation in martensite could significantly reduce the amount of carbon partitioning into austenite, e.g. incomplete carbon partitioning phenomenon, which would alter austenite decomposition behavior and austenite stability during the Quenching and Partitioning (Q&P) process. In this study, an integrated model is developed to clarify the mechanism of incomplete carbon partitioning and quantify its effects on austenite stabilization in the low-alloy medium-carbon Fe–C–Mn–Si steels. The fraction of carbon consumed by Cottrell atmospheres around dislocations is described using a semi-empiric equation. Then, the kinetic competition among carbide precipitation, carbon partitioning and austenite decomposition during the partitioning step is simulated by coupling the Deschamps–Bréchet model and quenching and partitioning-local equilibrium (QP-LE) model. It is found that transition carbide precipitation in martensite and carbon partitioning into austenite are kinetically coupled at the very early stage of the partitioning step and subsequently promotes austenite decomposition. Taking the synergy effects of incomplete carbon partitioning and austenite decomposition into account, our model is capable of predicting the evolution of volume fraction of austenite and its carbon content during partitioning.

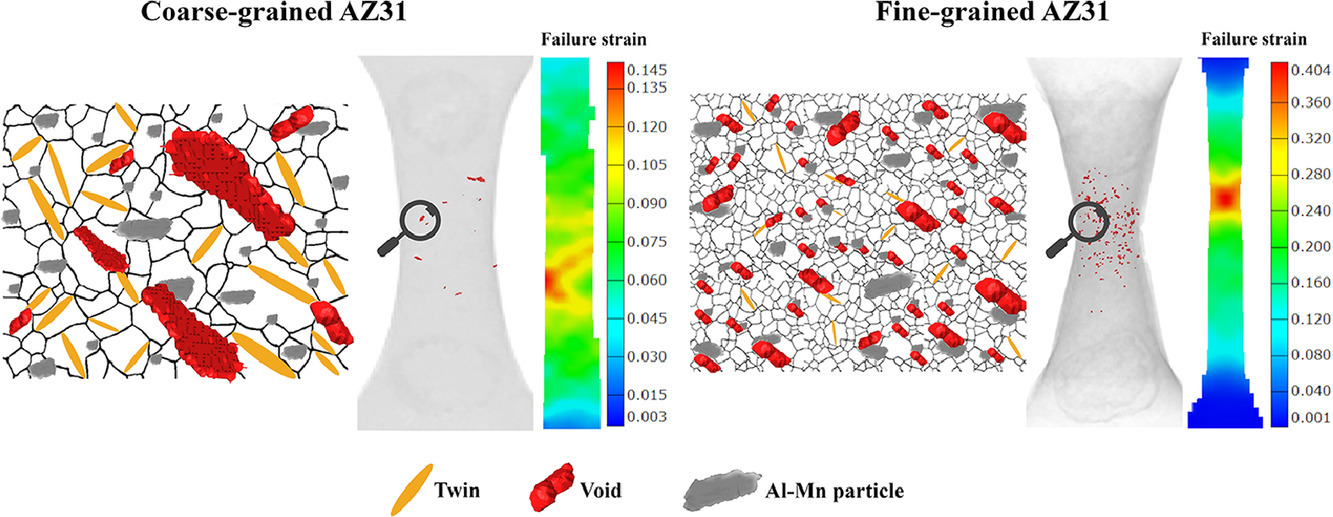

ACTA Vol. 200, Nov. 2020, P619-631

40. A rationale for the influence of grain size on failure of magnesium alloy AZ31: An in situ X-ray microtomography study

晶粒尺寸對AZ31鎂合金失效影響的原位X射線研究

S.H. Mohamadi Azghandi?, M. Weiss, B.D. Arhatari, J. Adriend, E. Maire, M.R. Barnett

S.H.M. Azghandi:h.mohamadiazghandi@deakin.edu.au

https://doi.org/10.1016/j.actamat.2020.09.016

摘要

在本研究中,我們采用了原位X射線衍射研究了晶粒尺寸對AZ31鎂合金拉伸過程中孔隙形成、長大和聯通的影響。研究表明,當晶粒尺寸由60μm下降到3μm時,合金斷裂應變提高了近3倍。晶粒細化阻礙了孿晶形成,降低了孔隙長大速率,但對孔隙密度隨應變的變化關系并無顯著影響。由于細晶的斷裂應變更大,因此在斷后細晶樣品中觀測到的孔隙密度也更高。相對地,斷裂時孔隙的總體分數與晶粒尺寸幾乎不隨晶粒尺寸變化。最終的斷裂看上去是由于孔隙形成引起剪切應力集中導致的。當孔隙體積分數到達臨界值后,會迅速引發失效,這與McClintock模型的預測結果基本一致。因此,孔隙增長率較低是細晶試樣斷裂應變提高的主要原因。晶粒細化對空隙增長的抑制作用可以解釋為什么晶粒較細的鎂合金通常具有較高的拉伸延展性。

英文摘要

The present study employs in situ X-ray microtomography to characterize the impact of grain size on void nucleation, growth and linkage during tensile loading of magnesium alloy AZ31. It was found that the tensile strain to failure increased almost threefold when the grain size was reduced from 60 to 3 μm. Grain refinement led to reduced twin formation and reduced void growth rates but did not impact markedly on the relationship between strain and the detected void number density. Because the finer grained samples experienced higher strains to failure, greater void number densities were thus detected at failure in these samples. The void volume fraction at failure remained constant despite changing grain size, within error. Final failure occurs via a shear localization and there appears to be a role of void formation in triggering the final shear instability. We thus favour ascribing failure to a void-sheeting type mechanism. Failure is seen to follow rapidly after a critical void volume fraction is attained and this is broadly consistent with predictions made via the application of a simple McClintock model. The higher strains to failure in the present fine-grained samples are thus ascribed chiefly to the lower rates of void growth. The suppression of void growth by grain refinement seen here may explain why finer grain magnesium alloys often display higher tensile ductility.

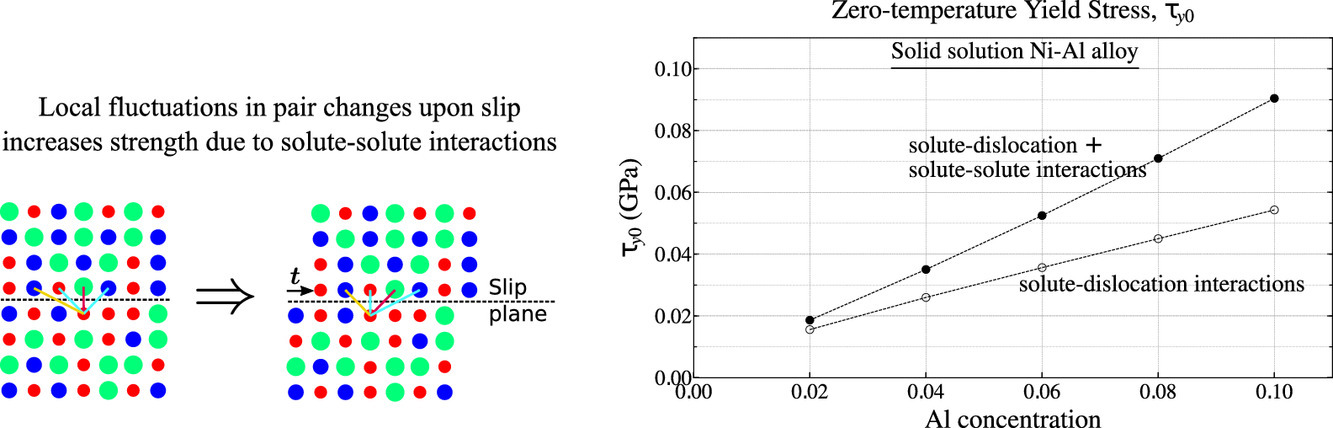

ACTA Vol. 200, Nov. 2020, P659-673

41. Effect of solute-solute interactions on strengthening of random alloys from dilute to high entropy alloys

溶質原子相互作用對隨機合金的強化作用

Shankha Nag?, William A. Curtin

S. Nag:shankha.nag@epfl.ch

https://doi.org/10.1016/j.actamat.2020.08.011

摘要

隨機合金,即所有溶質原子隨機占據晶格位置的合金,其屈服強度被認為主要由溶質/位錯相互作用控制。溶質原子的相互作用為短程和長程有序提供了驅動力,并即使在隨機合金,也會影響屈服強度。本研究中,我們將隨機合金的最新理論擴展至用于描述溶質的成對相互作用。這一理論計算了位錯滑移過程中溶質相互作用的能量標準差,并不斷改變穿過滑移面的溶質原子對,推導得到了標準差的解析表達式,并通過在2-5元模型隨機合金中進行數值模擬對表達式進行了驗證。我們將該理論分別應用于BCC MoNbTaW高熵合金的第一原理計算以及NbTaV合金模型的EAM勢中,發現材料的強度略微增加2%和0.45%。而當理論應用于隨機FCC Ni-Al合金時,由于Al-Al原子對作用很強的相互排斥作用,當Al為10% 時,根據輸入參數的不同,材料表現出60% - 100%的強度提升。我們將其與一些文獻中Ni-Al合金的原子尺度模擬進行了比較。總的來說,本理論提供了一個定量框架,對隨機合金中溶質-位錯相互作用和溶質原子相互作用的強化作用進行分析。

英文摘要

The yield strength of random metal alloys, i.e. alloys with random occupation of the crystalline lattice sites by the elemental constituent atoms all considered as solutes, is primarily understood as controlled by solute/dislocation interactions. Solute-solute interactions exist and provide the energetic driving force for both short-range and long-range order but can then also affect yield strength even in the random alloy. Here, a recent theory for random alloys is extended to include solute-solute interactions described by pair-wise interactions. The new theory involves the standard deviation in total solute-solute interaction energies as a dislocation segment glides through the material, which changes specific solute-solute pairs across the glide plane at every pair distance. An analytic expression is derived for the above standard deviation and validated against numerical simulations on a wide range of model random alloys consisting of 2–5 elements interacting via Lennard–Jones pair potentials. The theory is applied to the bcc MoNbTaW high entropy alloy, using solute-solute interactions computed via first-principles, and a model NbTaV alloy, described by EAM potentials, where the strength increases negligibly by 2% and 0.45%, respectively. Application to random dilute fcc Ni-Al, where the first-neighbor Al-Al interaction is very strongly repulsive, shows significant strengthening of 60–100% at 10% Al, depending on the origin of the inputs. Some connections to literature atomistic simulations on Ni–Al are also presented. Overall, the present theory provides a quantitative framework for assessing the relative roles of solute-dislocation and solute-solute interactions on strengthening in random alloys.

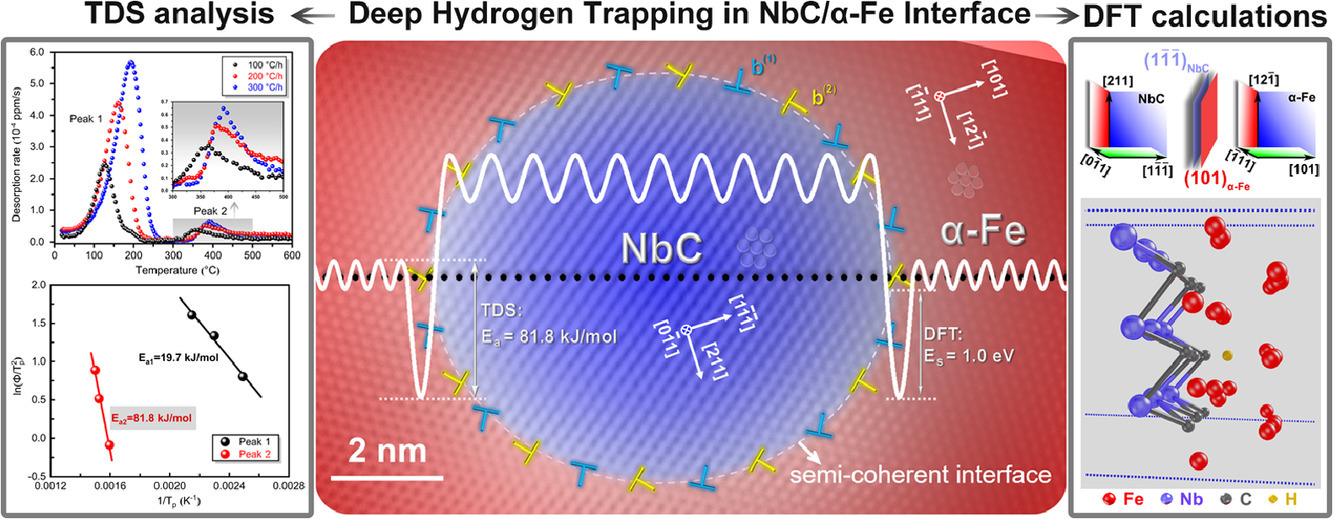

ACTA Vol. 200, Nov. 2020, P686-698

42. Atomic-scale investigation of deep hydrogen trapping in NbC/α-Fe semi-coherent interfaces

NbC/α-Fe半共格界面氫陷阱的原子尺度研究

Rongjian Shi, Yuan Ma, Zidong Wang, Lei Gao, Xu-Sheng Yang, Lijie Qiao?, Xiaolu Pang?

L. Qiao:lqiao@ustb.edu.cn,北京科技大學

X.Pang:pangxl@mater.ustb.edu.cn,北京科技大學

https://doi.org/10.1016/j.actamat.2020.09.031

摘要

碳化鈮的析出能夠較好地緩解氫脆。我們通過高分辨率透射電鏡對NbC/α-Fe半共格界面處的取向關系、原子排列和其他缺陷進行觀測,研究了NbC/α-Fe半共格界面對高強度回火馬氏體鋼氫脆性能的影響。觀測表明,NbC/α-Fe半共格界面遵循K-S位向關系。值得注意的是,界面上的兩組特定位錯是氫的有效捕獲位置,我們對其進行了詳細表征。基于密度泛函理論的第一線原理計算發現,NbC/α-Fe半共格界面與氫的結合能為0.80eV,這與熱吸收光譜實驗測得的氫活化能81.8 kJ/mol相匹配。這些結果表明NbC/α-Fe半共格界面本質上發揮氫俘獲作用的是位錯核。尺寸約為10.0±3.3 nm的非均勻分布NbC納米析出極大地增加了氫的捕獲,提高了清脆性能。綜上所述,在材料中大量引入NbC/α-Fe半共格界面是非常有效的抗氫脆鋼設計策略。

英文摘要

The precipitation of niobium carbide (NbC) is a superior approach to mitigating hydrogen embrit tlement (HE). The role of the semi-coherent interface between NbC and α-Fe on hydrogen trapping and HE resistance in high-strength tempered martensitic steel was investigated in this study. Highresolution transmission electron microscopy observations are performed to reveal the atomic-scale crystallographic orientation relationship, atomic arrangements, and associated crystalline defects in the NbC/α-Fe semi-coherent interface. We observed the Kurdjumov–Sachs orientation relationship with (1-1-1)NbC // (101)α−Fe and [0-11]NbC // [-111]α−Fe between the NbC and α-Fe phases. Noticeably, two sets of misfifit dislocations with Burgers vectors of b(1) =ab/2[111] on (01-1) α-Fe planes and b(2) = ab/2[111] on (110) α-Fe planes (ab is the lattice constant of α-Fe), which would be the deep hydrogen trapping sites, were characterized in the NbC/α-Fe semi-coherent diffuse interface. In addition, density functional theory-based first-principles calculations revealed that the deep binding energy between the NbC/α-Fe semi-coherent interface and hydrogen is 0.80 eV, which well matches the hydrogen desorption activation energy of 81.8 kJ/mol determined via thermal desorption spectroscopy experiments. These demonstrate that the nature of the deep hydrogen trapping sites of the NbC/α-Fe semi-coherent interface is the misfit dislocation core. Distinguished HE resistance was obtained and ascribed to the deep hydrogen trapping of uniformly dispersed NbC nanoprecipitates with an average diameter of 10.0 ± 3.3 nm. The strategy of deep hydrogen trapping in the NbC/α-Fe semi-coherent interface is beneficial for designing HE-resistant steels.

微信公眾號:Goal Science

投稿郵箱:wechat@gs-metals.com

投稿微信:GSmaterial