金屬頂刊雙語導讀丨Scripta Mater. Vol.200, 15 July. 2021(下)

2021-06-06 來源:GS_Metals

本期包含金屬材料領域論文11篇,涵蓋了高熵合金、奧氏體鋼、高溫合金等,國內科研單位包括上海交通大學、吉林大學等(通訊作者單位)。

Vol. 200 目錄

1. Mn-stabilized austenitic steel strengthened by nano-scale β-NiAl (B2), FCC-Cu, and carbides via ICME design

通過ICME設計,采用納米尺度β-NiAl(B2),FCC-Cu和碳化物強化Mn穩定的奧氏體鋼

2. A binary beta titanium superalloy containing ordered-beta TiFe, alpha and omega

一種包含有序β-TiFe,α和ω的二元β鈦高溫合金

3. Origin of high tension-compression yield asymmetry in as-extruded pure zinc

擠壓態純鋅高拉伸-壓縮屈服不對稱性的成因

4. Novel eutectoid Ti-5Ni alloy fabricated via direct energy deposition

采用直接能量沉積制備新型共晶Ti-5Ni合金

5. Hardening induced by dislocation core spreading at disordered interface in Cu/Nb multilayers

Cu/Nb多層膜中無序界面處位錯核擴展引起的硬化

6. On temperature and strain-rate dependence of flow serration in HfNbTaTiZr high-entropy alloy

HfNbTaTiZr高熵合金流動鋸齒的溫度和應變速率依賴性研究

7. The {10-12} non-cozone twin-twin interactions in Mg: A stability and mobility study using 3-D atomistic simulations

Mg中{10-12}非同域孿生相互作用:使用三維原子模擬的穩定性和遷移率研究

8. Yielding behavior of a single-crystalline γ'-strengthened Co-Ti-Cr superalloy

單晶γ'強化Co-Ti-Cr高溫合金的屈服行為

9. New Ms-formula for exact microstructural prediction of modern 3rd generation AHSS chemistries

新的Ms公式可精確預測不同化學成分的第三代AHSS的微觀組織

10. Plastic deformation of solid-solution strengthened Hf-Nb-Ta-Ti-Zr body-centered cubic medium/high-entropy alloys

固溶強化Hf-Nb-Ta-Ti-Zr體心立方中/高熵合金的塑性變形

11. Pre-strain mediated fast natural aging in a dilute Mg-Zn-Ca-Sn-Mn alloy

預應變介導的Mg-Zn-Ca-Sn-Mn稀釋合金的快速自然時效

SCRIPTA

Vol. 200, 15 July. 2021, 113903

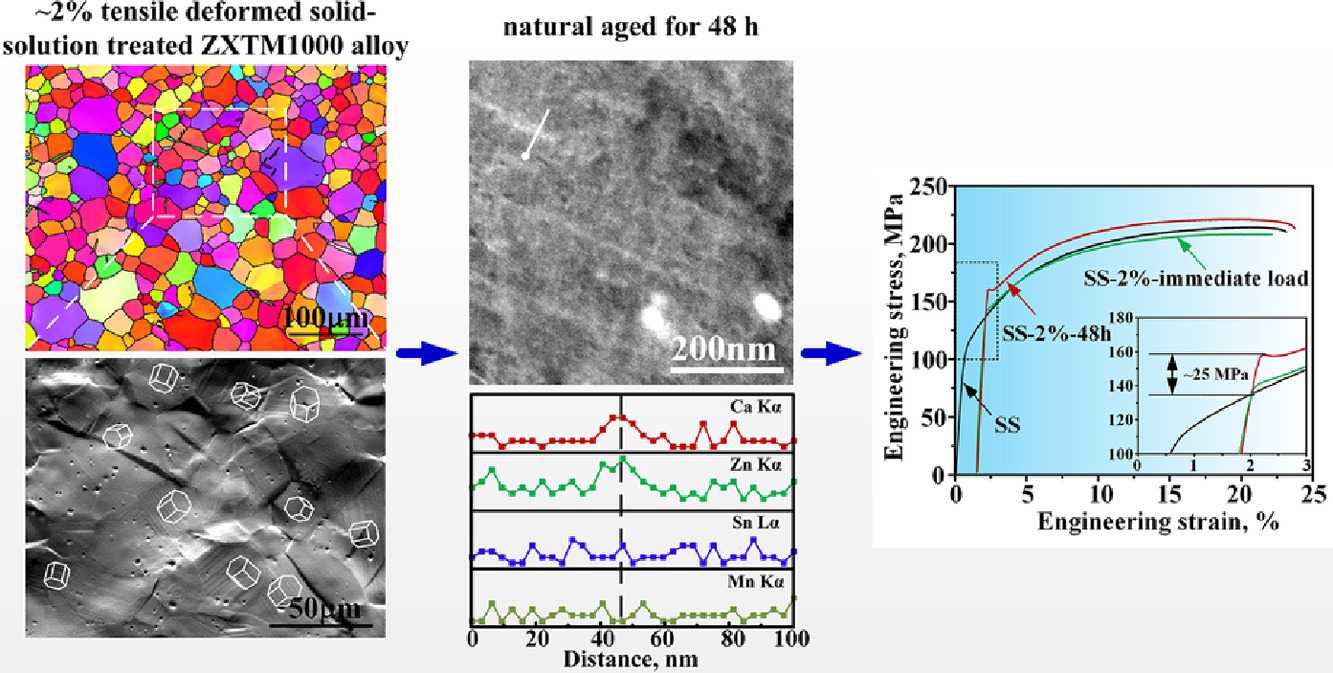

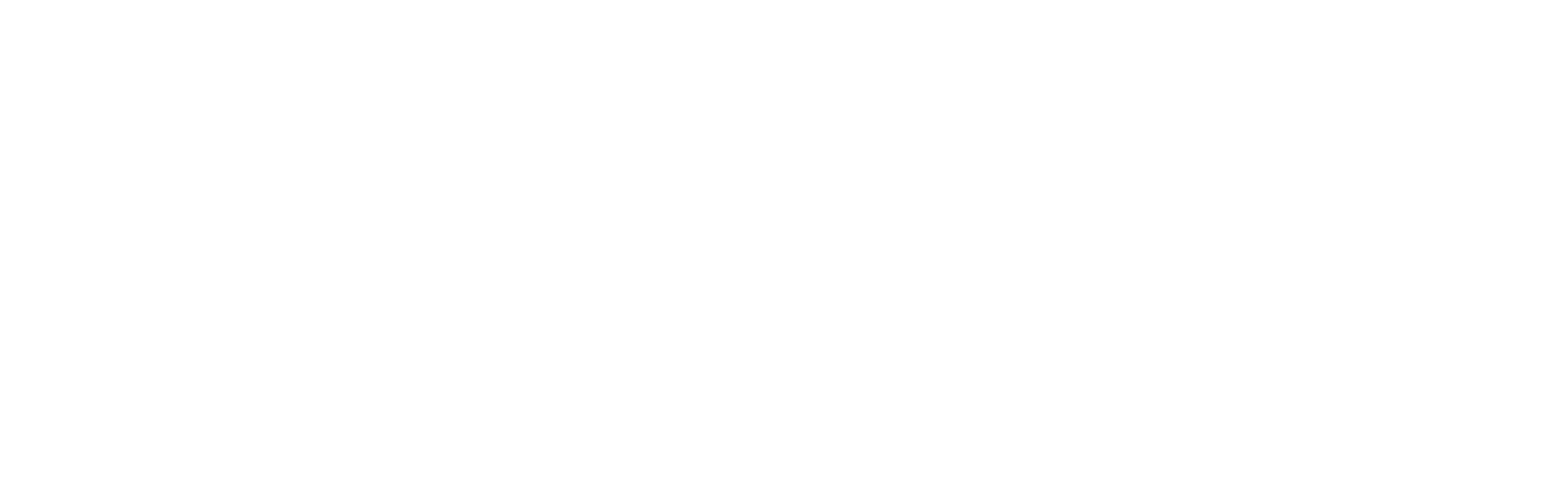

1. Mn-stabilized austenitic steel strengthened by nano-scale β-NiAl (B2), FCC-Cu, and carbides via ICME design

通過ICME設計,采用納米尺度β-NiAl(B2),FCC-Cu和碳化物強化Mn穩定的奧氏體鋼

Colin A. Stewart?, Richard W. Fonda, Keith E. Knipling

Colin A. Stewart: colin.stewart.ctr@nrl.navy.mil

https://doi.org/10.1016/j.scriptamat.2021.113903

摘要

采用集成計算材料工程(ICME)的方法設計了由β-NiAl、FCC-Cu和M23C6碳化物這三種納米尺度析出相強化的Mn穩定全奧氏體鋼。采用Thermal-Calc預測了Ni、Al和Cu對Fe-17.7Mn-4.7Cr-0.48C (wt.%)基奧氏體成分相穩定性的影響。通過實驗(1)合成Cu、Ni+Al或Cu+Ni+Al改性的奧氏體基合金,(2)通過微壓痕測量力學性能,(3)通過原子探針斷層掃描(APT)表征納米尺度的微觀結構,驗證了上述預測。根據Thermal-Calc模型,在580℃時效后,Cu或Ni+Al改性的樣品只有輕微的硬化。Cu+Ni+Al復合合金展現出強烈的硬化效果(強度為490 HV,σy≈1200 MPa),這主要歸因于FCC-Cu和β-NiAl納米相的形成。

SCRIPTA

Vol.200, 15 July. 2021, 113905

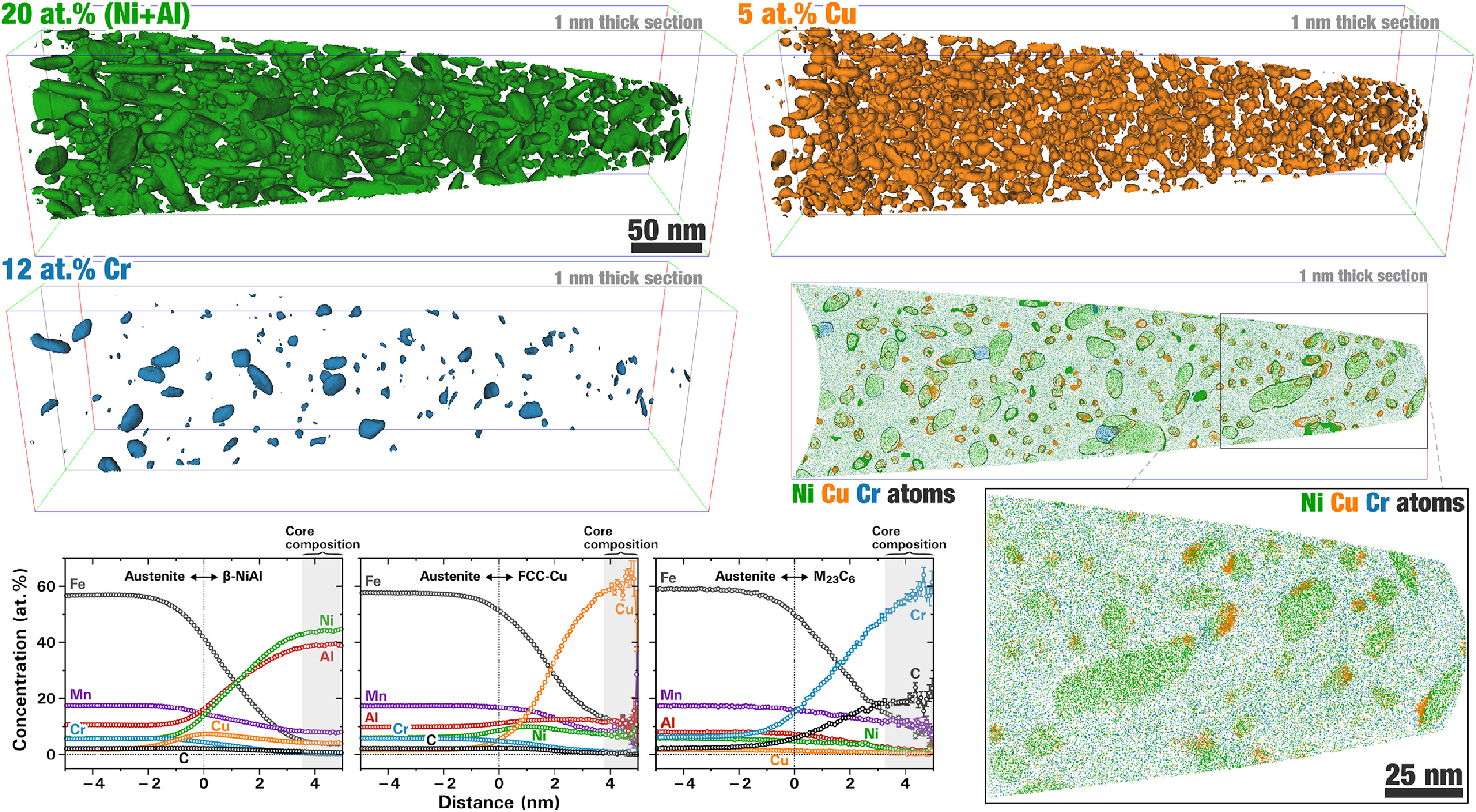

2. A binary beta titanium superalloy containing ordered-beta TiFe, alpha and omega

一種包含有序β-TiFe,α和ω的二元β鈦高溫合金

R. D. Jones?, A.J. Knowles, W.J. Clegg

R. D. Jones: robert.jones48@ntlworld.com

https://doi.org/10.1016/j.scriptamat.2021.113905

摘要

α-β鈦合金適用于航空發動機,但通常限制在~550°C。另一種策略是用有序β- TiFe金屬間化合物增強“β-Ti高溫合金”,然而,目前對二元體系中TiFe析出的研究很少。本研究將Ti-20Fe (at.%)合金在β-Ti相區進行1050°C的均勻化處理,然后在600°C進行時效,時效過程中Fe的過飽和促進了TiFe的析出。結果表明,隨著TiFe體積分數的增加,合金的硬度降低,主要原因是:(1) 時效過程中β-Ti Fe含量降低至16.2%,Fe的固溶強化降低;(2) 透射電鏡觀察發現,均勻化的β-Ti母相中類ω的不相稱調制域在時效后,其尺寸和結構發生變化,導致ω析出的強化減弱;(3) 從較硬的ω強化β-Ti母相析出較軟的TiFe和α-Ti相而發生軟化。

SCRIPTA

Vol. 200, 15 July. 2021, 113922

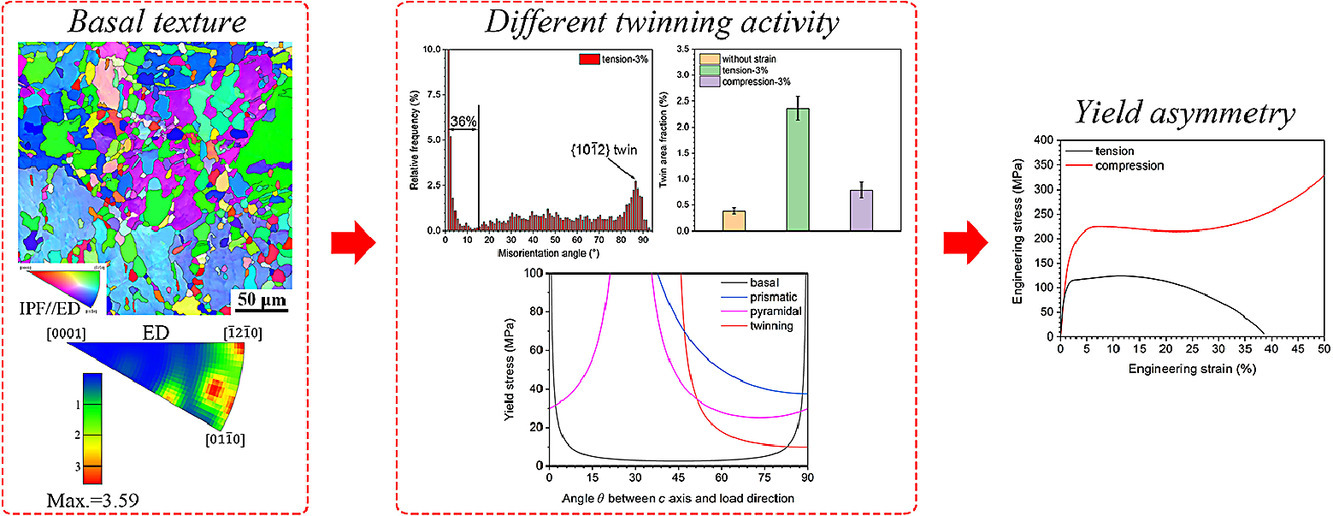

3. Origin of high tension-compression yield asymmetry in as-extruded pure zinc

擠壓態純鋅高拉伸-壓縮屈服不對稱性的成因

Chun Chen, Hua Huang?, Jialin Niu, Jian-Feng Nie?, Guangyin Yuan?

Hua Huang: huangh@sjtu.edu.cn 上海交通大學

Jian-Feng Nie: jianfeng.nie@monash.edu

Guangyin Yuan: gyyuan@sjtu.edu.cn 上海交通大學

https://doi.org/10.1016/j.scriptamat.2021.113922

摘要

鋅及其合金因其作為生物可降解植入物的潛力而受到越來越多的關注。然而,鋅及其合金在塑性成形后存在明顯的拉-壓屈服不對稱性,這是不希望出現的。本文研究了擠壓態純鋅中強烈的拉伸-壓縮屈服不對稱性,揭示了拉伸狀態下較高的{10-12}⟨-1011⟩孿晶活性是其根本原因。在此基礎上,我們提出弱化織構和細化晶粒是降低拉-壓屈服不對稱性的有效策略。

SCRIPTA

Vol. 200, 15 July. 2021, 113918

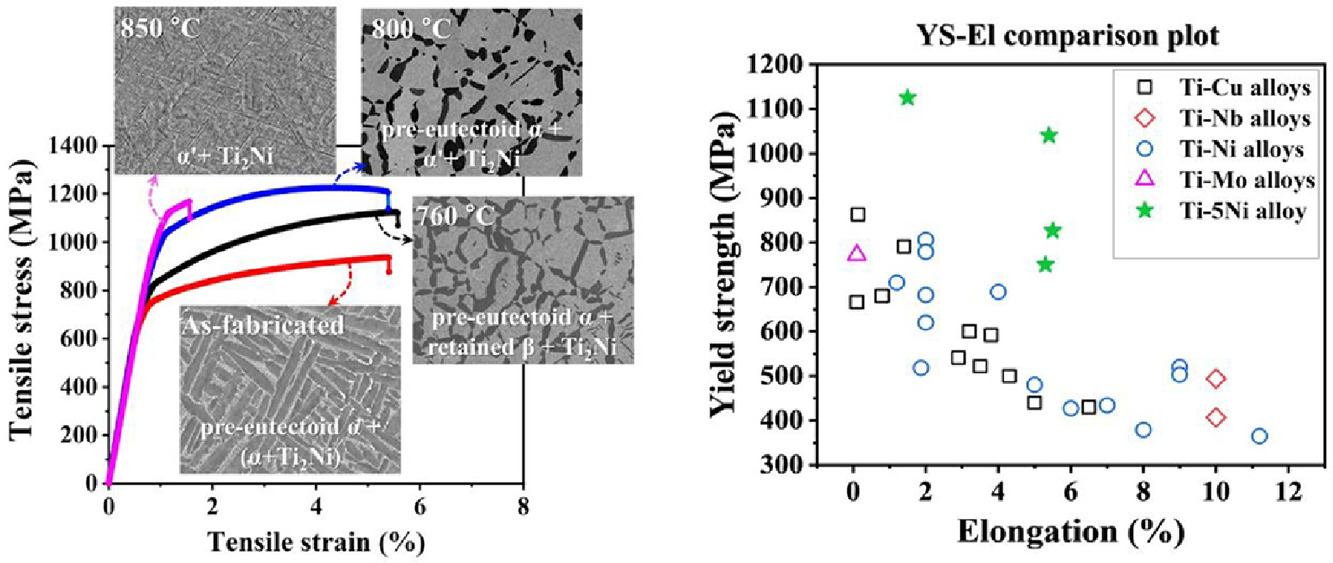

4. Novel eutectoid Ti-5Ni alloy fabricated via direct energy deposition

采用直接能量沉積制備新型共晶Ti-5Ni合金

P. L. Narayana, Jae H. Kim?, Sangwon Lee, Jong Woo Won, Chan Hee Park, Jong-Taek Yeom, N.S. Reddy, Jae-Keun Hong?

Jae H. Kim: jaehkim@kims.re.kr

Jae-Keun Hong: jkhong@kims.re.kr

https://doi.org/10.1016/j.scriptamat.2021.113918

摘要

直接能量沉積Ti-5Ni (wt.%)合金促進了顯著的晶粒細化,具有細小的等軸晶粒(~ 30-50 μm);具有不連續的晶界α、細小共晶α條(寬度約1 μm)和α+Ti2Ni相。在低于β轉變溫度下進行24 h的后處理,促進了近等軸相α的形成,溫度顯著影響了組織組成,包括預共析相α+保留相β+Ti2Ni(760°C)、預共析相α+α' +Ti2Ni(800°C)和完全α' +Ti2Ni(850°C)。與其他常規處理的Ti-Ni二元共晶合金相比,制備態和熱處理態合金的拉伸性能顯著提高。因此,本文提出的方法為更高效率制備其他共析成形合金系統開辟了新的機會和可能性,這可以克服其他制備工藝的局限性。

SCRIPTA

Vol. 200, 15 July. 2021, 113917

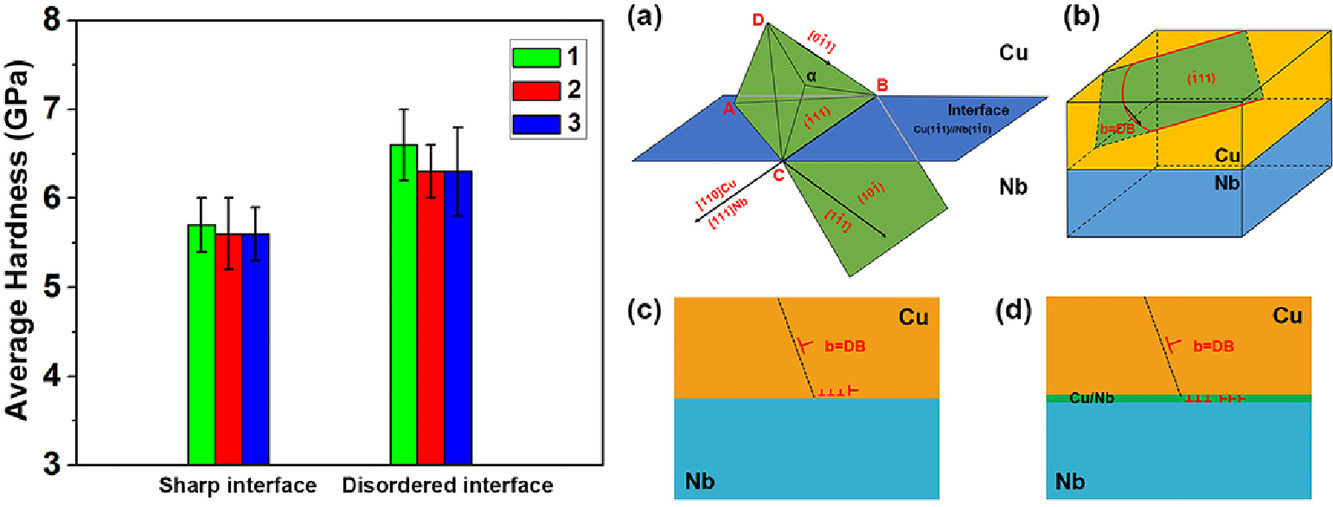

5. Hardening induced by dislocation core spreading at disordered interface in Cu/Nb multilayers

Cu/Nb多層膜中無序界面處位錯核擴展引起的硬化

Wenfan Yang, Mingyu Gong, Jiahao Yao, Jiangwei Wang, Shijian Zheng?, Xiuliang Ma

Shijian Zheng: sjzheng@hebut.edu.cn 沈陽材料科學國家實驗室;河北工業大學

https://doi.org/10.1016/j.scriptamat.2021.113917

摘要

原子尺度界面結構可以調整界面處的位錯行為,并強化界面。在本研究中,我們通過在Cu/Nb多層膜中引入超薄非晶層來設計無序界面。與尖銳界面相比,無序界面可以松弛平面內和平面外的伯氏矢量,涂抹釘扎的位錯,從而在Cu/Nb多層膜中引起顯著的硬化。這一發現不僅證明了位錯界面涂抹所引起的硬化效應,而且為采用無序界面開發超高硬度先進材料提供了思路。

SCRIPTA

Vol. 200, 15 July. 2021, 113919

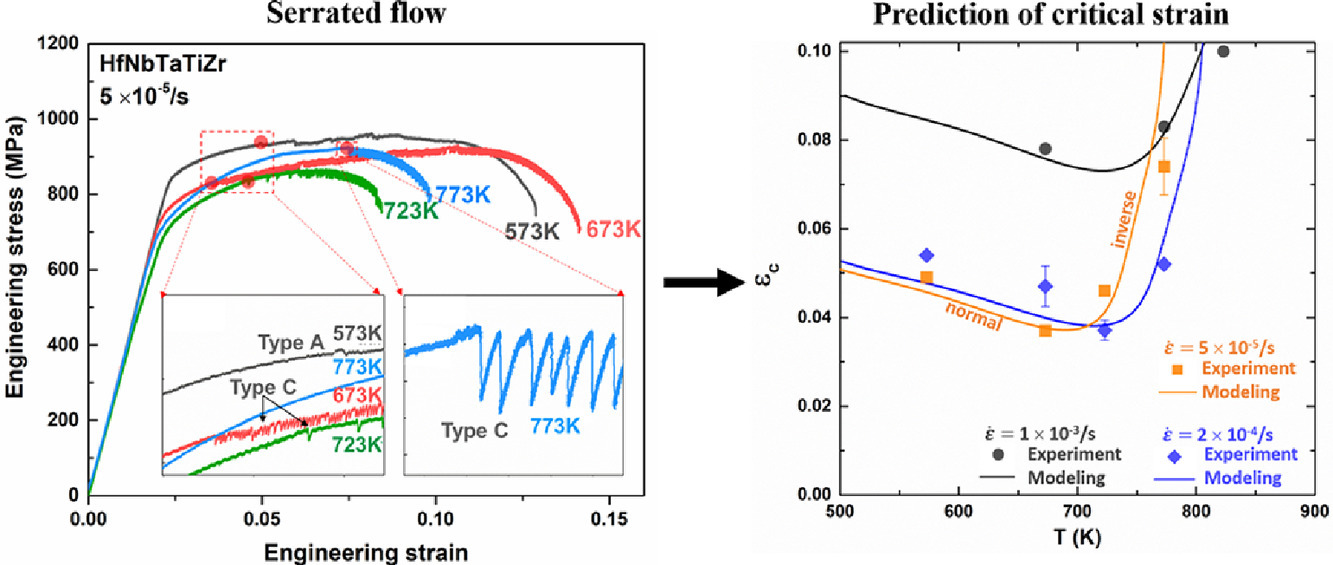

6. On temperature and strain-rate dependence of flow serration in HfNbTaTiZr high-entropy alloy

HfNbTaTiZr高熵合金流動鋸齒的溫度和應變速率依賴性研究

Shuying Chen, Weidong Li?, Fanchao Meng, Yang Tong, Hua Zhang, Ko-Kai Tseng, Jien-Wei Yeh, Yang Ren, Fei Xu, Zhenggang Wu?, Peter K. Liaw?

Weidong Li: wli20@utk.edu

Zhenggang Wu: zwu9@hnu.edu.cn 湖南大學

Peter K. Liaw: pliaw@utk.edu

https://doi.org/10.1016/j.scriptamat.2021.113919

摘要

金屬合金在應力-應變曲線上表現為鋸齒狀流動的塑性失穩現象通常不利于合金的加工和制造。本文報道了HfNbTaTiZr合金中的流動鋸齒,并通過實驗研究了其對于溫度(573-823K)和應變速率(5×10-5 s-1-1× 10-3 s-1)的依賴關系。在一定的應變速率下,隨著溫度的升高,鋸齒狀流動的起始應變由下降(正態)向上升(逆態)的顯著轉變被理論框架成功地模擬了出來。該模型成功地預測了起始應變作為溫度和應變速率的函數,這表明在理論上為受測合金建立處理窗口的可能性。

SCRIPTA

Vol. 200, 15 July. 2021, 113913

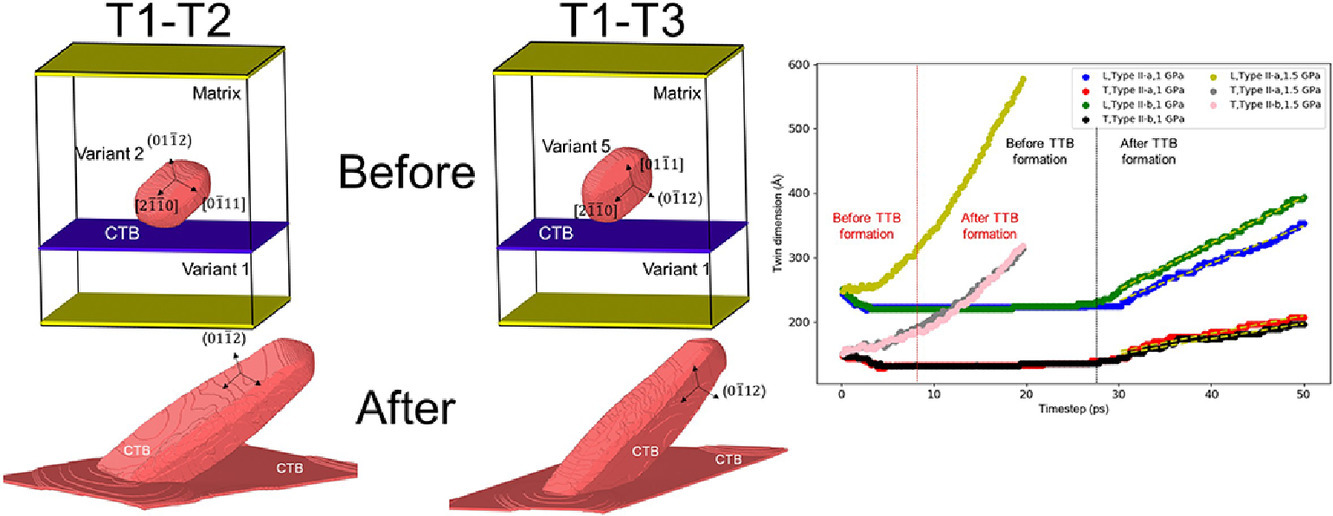

7. The {10-12} non-cozone twin-twin interactions in Mg: A stability and mobility study using 3-D atomistic simulations

Mg中{10-12}非同域孿生相互作用:使用三維原子模擬的穩定性和遷移率研究

Khanh Dang?, Carlos N. Tomé, Laurent Capolungo

Khanh Dang: kqdang@lanl.gov

https://doi.org/10.1016/j.scriptamat.2021.113913

摘要

由于Mg中拉伸孿晶容易激活,多個{10-12}孿晶變體可以相互作用,在塑性變形過程中形成孿晶界。之前使用二維模擬的研究只提供了這些相互作用的部分理解,特別是非同域的交互作用。本文采用原子模擬方法研究了非同域{10-12}孿晶結的三維結構特征和演化過程。研究表明,基底棱柱和具有共格孿晶界的共軛孿晶界面發生相互作用后,會形成新的孿晶界(TTBs),如TTBBP和TTBK2。對于兩種非共域孿生相互作用,{-12-12}TTB及其相關的孿晶結對{10-12}孿晶的穩定性和遷移率起著重要作用。特別地,在相互作用過程中它們促進了三維孿晶在法向和正向上的生長,在卸載時阻礙了去孿晶過程。

SCRIPTA

Vol. 200, 15 July. 2021, 113928

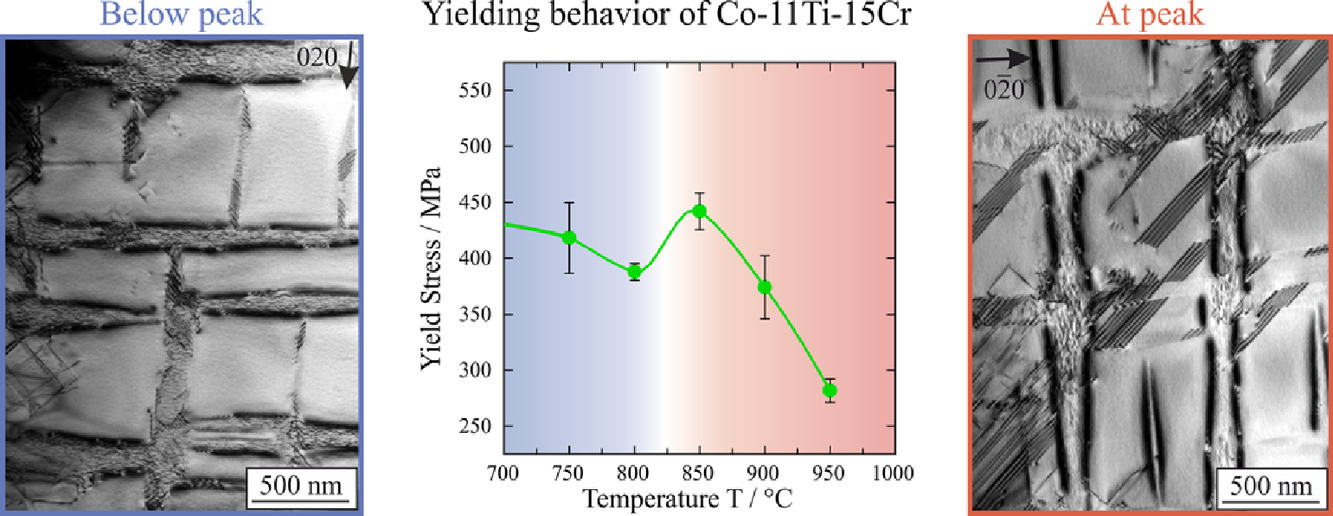

8. Yielding behavior of a single-crystalline γ'-strengthened Co-Ti-Cr superalloy

單晶γ'強化Co-Ti-Cr高溫合金的屈服行為

A. Bezold?, N. Volz, M. Lenz, C.H. Zenk, E. Spiecker, M. Mills, M. Göken, S. Neumeier

A. Bezold: andreas.bezold@fau.de

https://doi.org/10.1016/j.scriptamat.2021.113928

摘要

Ni3Al或Ni基高溫合金的異常屈服行為可以用不可動位錯構型來解釋,這是由反相界耦合位錯對的交滑移形成的。本文用透射電鏡對單晶Co-11Ti-15Cr高溫合金的反常屈服行為進行了系統研究,發現在屈服初期沒有形成類似的不動位錯構型。γ′析出相在峰值溫度下的主要變形機制是超晶格層錯的形成。此外,高密度的超晶格層錯及其相互作用也導致了明顯的加工硬化異常。

SCRIPTA

Vol. 200, 15 July. 2021, 113923

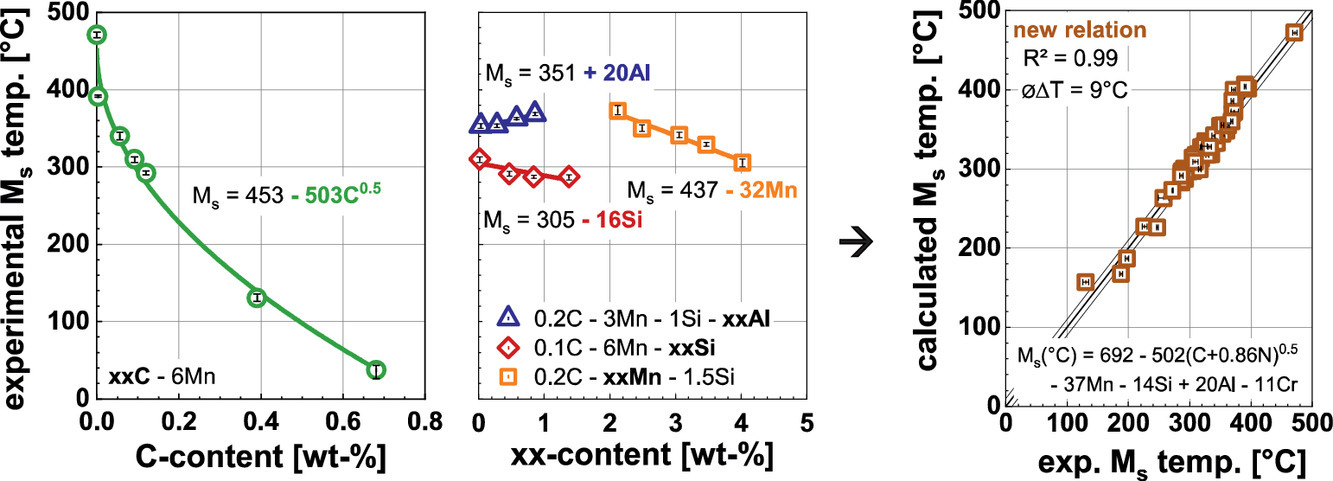

9. New Ms-formula for exact microstructural prediction of modern 3rd generation AHSS chemistries

新的Ms公式可精確預測不同化學成分的第三代AHSS的微觀組織

Simone Kaar?, Katharina Steineder, Reinhold Schneider, Daniel Krizan, Christof Sommitsch

Simone Kaar: simone.kaar@fh-wels.at

https://doi.org/10.1016/j.scriptamat.2021.113923

摘要

對于第三代先進高強度鋼(AHSS)來說,精確調整各個微觀組織組成,特別是亞穩殘余奧氏體(RA)的最佳體積分數是非常必要的。此外,避免在最終冷卻時形成新鮮馬氏體(α′)是至關重要的,否則將導致這些新鋼種的力學性能發生明顯惡化。因此,準確估算馬氏體相變起始溫度(Ms)對這組鋼的建模和發展是至關重要的。在此背景下,本文基于第三代AHSS化學成分,提出了一個具有寬成分范圍的Ms溫度預測的新關系。此外,新的Ms公式可以精確預測極低和非常高C含量鋼種的Ms溫度,這是文獻中已知的任何Ms公式所不能實現的。

SCRIPTA

Vol. 200, 15 July. 2021, 113927

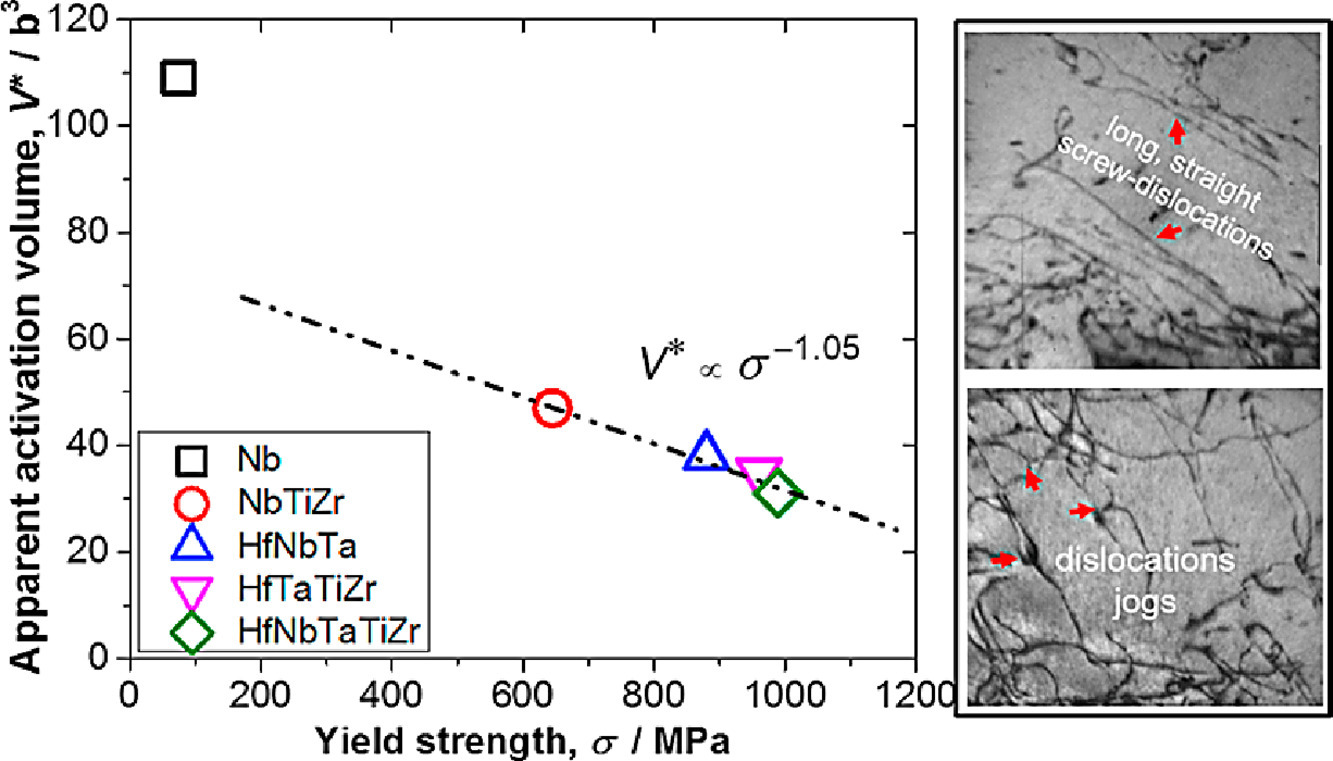

10. Plastic deformation of solid-solution strengthened Hf-Nb-Ta-Ti-Zr body-centered cubic medium/high-entropy alloys

固溶強化Hf-Nb-Ta-Ti-Zr體心立方中/高熵合金的塑性變形

Rajeshwar R. Eleti?, Nikita Stepanov, Nikita Yurchenko, Denis Klimenko, Sergey Zherebtsov

Rajeshwar R. Eleti: rajeshwar.eleti@gmail.com

https://doi.org/10.1016/j.scriptamat.2021.113927

摘要

研究了不同體心立方(BCC)中/高熵合金(MEAs/HEAs)在300K拉伸變形過程中的塑性變形和速率控制機制。微觀組織觀察顯示長而直的螺位錯,偶爾由割階組成。變形的亞結構與評估的激活體積(V*)一致,表明螺位錯運動克服Peierls-Nabarro應力阻礙作為速率控制機制。V*值與屈服強度成反比。V*作為屈服強度函數的單調行為表明BCC-MEAs/HEAs的位錯運動必須同時克服涉及多個/群置換溶質原子的能壘。此外,首次在BCC-MEAs/HEAs中觀察到應力等效現象。研究結果描述了固溶強化BCC-MEAs/HEAs的熱激活位錯滑移機制取決于應力而不是合金的化學復雜性。

SCRIPTA

Vol. 200, 15 July. 2021, 113924

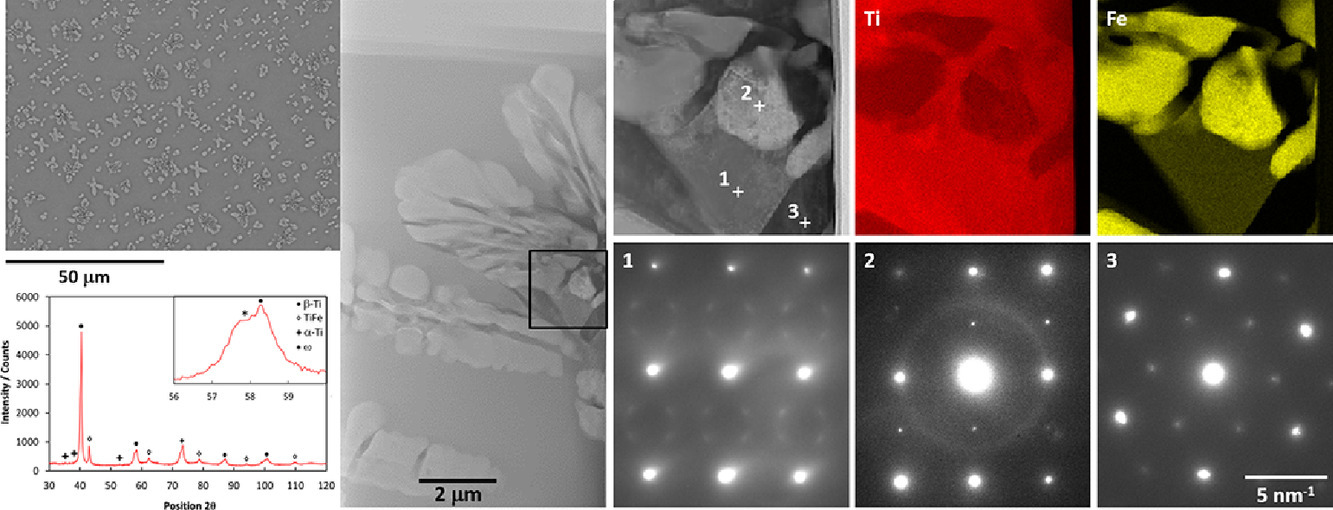

11. Pre-strain mediated fast natural aging in a dilute Mg-Zn-Ca-Sn-Mn alloy

預應變介導的Mg-Zn-Ca-Sn-Mn稀釋合金的快速自然時效

Zhen-Ming Hua, Mei-Xuan Li, Cheng Wang?, Xiao Shi, Zhao-Yuan Meng, Yi-Jia Li, Hai-Long Jia, Min Zha, Hui-Yuan Wang?

Cheng Wang: chengwang@jlu.edu.cn 吉林大學

Hui-Yuan Wang: wanghuiyuan@jlu.edu.cn 吉林大學

https://doi.org/10.1016/j.scriptamat.2021.113924

摘要

稀釋Mg-1.0Zn-0.45Ca-0.33Sn-0.2Mn (wt.%,ZXTM1000)合金板材經預應變處理后,產生了顯著的自然時效(NA)響應,在48小時內流應力從~138 MPa明顯增加到了~163 MPa。預應變變形引入了大量基底為<a>的位錯和過飽和非平衡空位,有利于溶質擴散過程,從而導致能量最小化的非均勻溶質分布。Zn和Ca原子的共偏析阻礙了位錯運動,這是強化效應的主要原因。本工作揭示了在稀釋鎂合金中由于晶體缺陷的引入而出現的明顯NA現象,同時也揭示了環境溫度下相關的組織演變,為高性能低成本鎂合金的設計提供了一種新的策略。