金屬頂刊雙語導讀丨Acta Mater. Vol.212,15 Jun. 2021(上)

2021-08-08 來源:Goal Science

本期包含金屬材料領域論文11篇,涵蓋了奧氏體、孿晶、高熵合金等,國內科研單位包括深圳大學等(通訊作者單位)。

Vol. 212 目錄

1. A novel 3D mixed-mode multigrain model with efficient implementation of solute drag applied to austenite-ferrite phase transformations in Fe-C-Mn alloys

Fe-C-Mn合金奧氏體-鐵氧體相變過程中溶質拖曳的3D混合模型

2. Atomic structures of interfacial solute gateways to θ’ precipitates in Al-Cu alloys

Al-Cu合金中θ′相界面溶質通道的原子結構研究

3. Columnar grain-driven plasticity and cracking in nanotwinned FCC metals

FCC納米孿晶柱狀晶的塑性與開裂

4. Dynamic recrystallization of Silver nanocubes during high-velocity Impacts

銀納米立方體在高速沖擊下的動態再結晶

5. Dynamic strain aging mechanisms in a metastable austenitic stainless steel

亞穩奧氏體不銹鋼的動態應變時效機制研究

6. Effect of sulfur on the glass-forming ability, phase transformation, and thermal stability of Cu-Zr-Al bulk metallic glass

硫對Cu-Zr-Al塊體金屬玻璃形成能力、相變和熱穩定性的影響

7. Free surface impact on radiation damage in pure nickel by in-situ self-ion irradiation: can it be avoided?

能否避免自由表面對純鎳原位自離子輻照損傷的影響?

8. Increased magnetocaloric response of FeMnNiGeSi high-entropy alloys

FeMnNiGeSi高熵合金的磁熱響應研究

9. Influence of microstructure and atomic-scale chemistry on the direct reduction of iron ore with hydrogen at 700°C

鐵礦石在700℃氫氣還原過程中的微觀結構和成分演化

10. In situ study of non-equilibrium solidification of CoCrFeNi high-entropy alloy and CrFeNi and CoCrNi ternary suballoys

CoCrFeNi、CrFeNi和CoCrNi合金非平衡凝固的原位研究

11. Intercritical annealing of cold-rolled ferrite-pearlite steel: Microstructure evolutions and phase transformation kinetics

冷軋珠光體-鐵素體鋼臨界退火過程中的組織演變和相變動力學研究

ACTA

Vol. 212,15 Jun. 2021, 116897

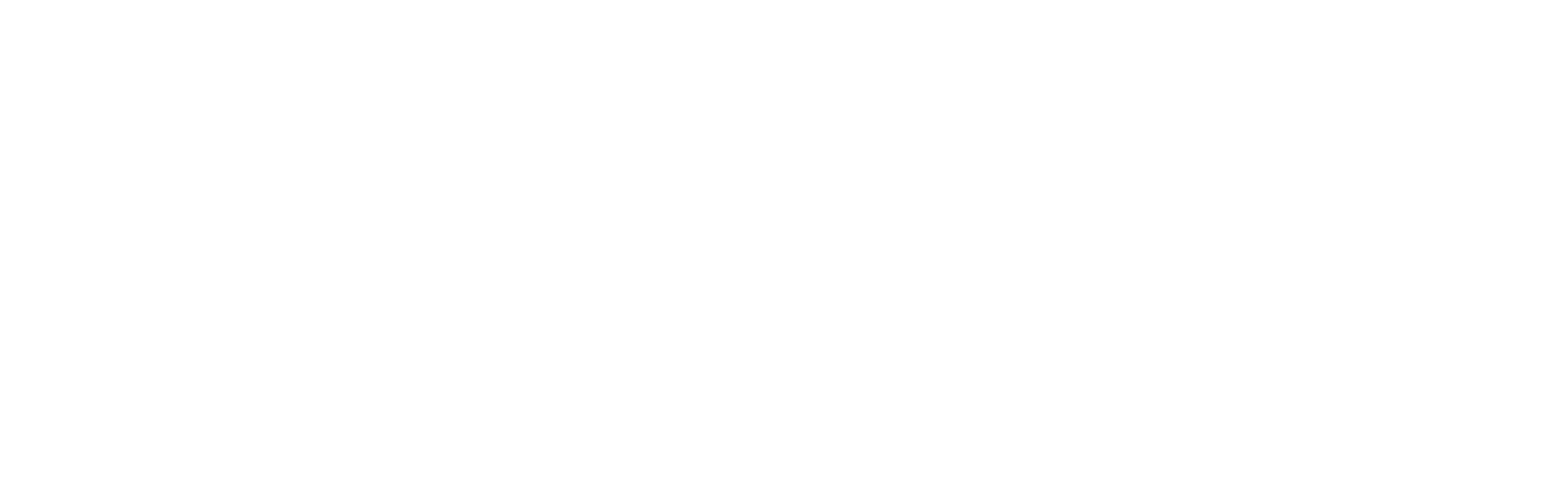

1. A novel 3D mixed-mode multigrain model with efficient implementation of solute drag applied to austenite-ferrite phase transformations in Fe-C-Mn alloys

Fe-C-Mn合金奧氏體-鐵氧體相變過程中溶質拖曳的3D混合模型

H. Fang?, S. van der Zwaag, N.H. van Dijk

H. Fang:h.fang@tudelft.nl, hfang@mek.dtu.dk, haixingfang868@gmail.com

https://doi.org/10.1016/j.actamat.2021.116897

摘要

同時考慮形核和界面遷移的三維模型是研究低合金鋼復雜組織的有效工具。本研究中,我們開發了一個能在任意熱處理路線下跟蹤擴散界面,從而模擬奧氏體-鐵素體相變和鐵素體-奧氏體相變的三維多晶混合模型。模型考慮了置換型元素的溶質拖曳效益,并且當材料發生從加熱到冷卻的轉變時,相變的方向也能夠自發地隨之改變。我們給出了計算溶質拖曳能量耗散的解析解,并結合化學勢的多元回歸逼近,大大加快了計算速度。我們首先以Fe-0.1C-0.5Mn (wt.%)合金為例,在不同的連續冷卻和等溫條件進行了計算。模型能夠很好地模擬由于相鄰晶粒的相互作用而導致的單一晶粒相變動力學差異。隨后我們應用該模型對一系列Fe-C-Mn合金在循環相變過程中的動力學進行了預測。與實驗結果的比較很好地驗證了該模型關于鐵素體相變動力學隨Mn含量變化的預測。模型的創新點在于能夠高效計算溶質拖曳的能量耗散、預測晶粒組織狀態、且需要擬合的參數少。模型代碼已公開。

ACTA

Vol. 212,15 Jun. 2021, 116891

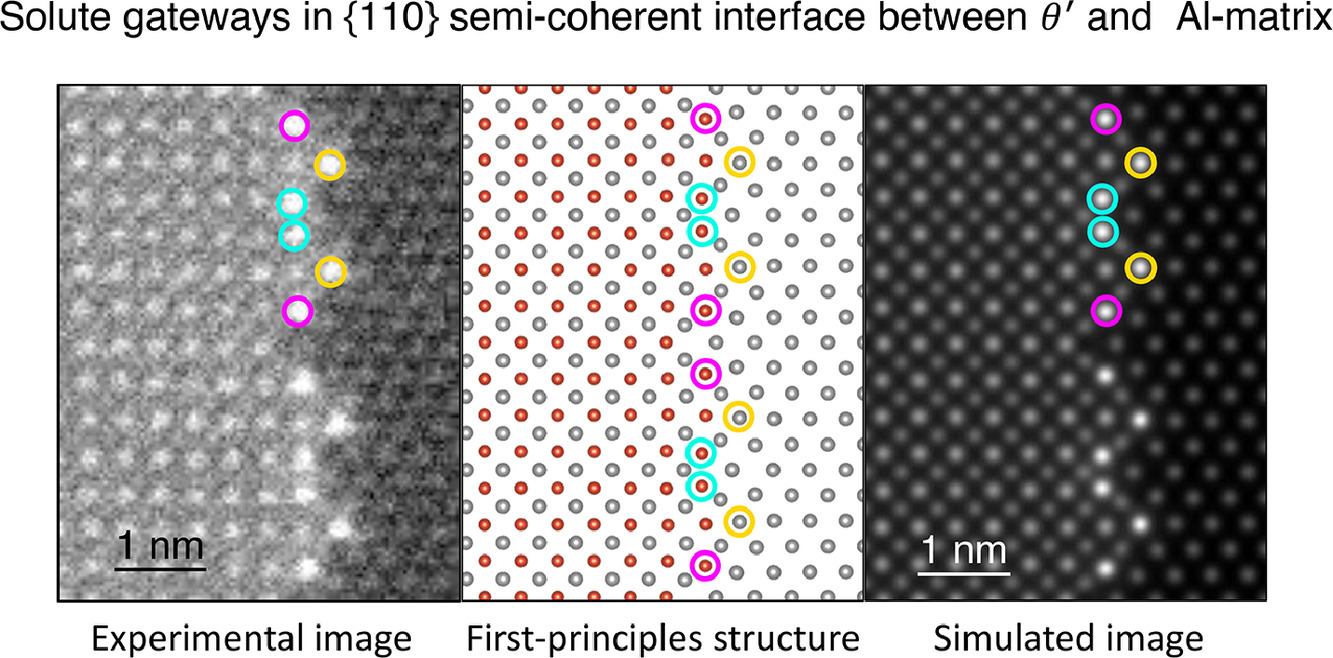

2. Atomic structures of interfacial solute gateways to θ’ precipitates in Al-Cu alloys

Al-Cu合金中θ′相界面溶質通道的原子結構研究

M.F. Chisholm?, D. Shin, G. Duscher, M.P. Oxley, L.F. Allard, J.D. Poplawsky, A. Shyam

M.F. Chisholm:chisholmmf@ornl.gov

https://doi.org/10.1016/j.actamat.2021.116891

摘要

亞穩強化相在高溫下的轉變或溶解對于材料性能至關重要。我們利用畸變校正掃描透射電子顯微鏡和第一性原理計算,對Al-Cu體系中的典型θ析出相Al2Cu的高移動性半共格界面的原子結構進行了研究。研究表明,半共格{110}界面由兩種在不同結構單元中排列的錯配配位錯列組成。位錯是鋁基體和強化相間幾乎所有錯配的產生原因。Cu在界面特定位置的位錯核受壓邊緣偏聚。第一性原理計算從能量角度對Cu原子在半共格界面處的運動進行了解釋。研究揭示了影響析出強化合金熱穩定性的半共格界面的關鍵特征。

ACTA

Vol. 212,15 Jun. 2021, 116925

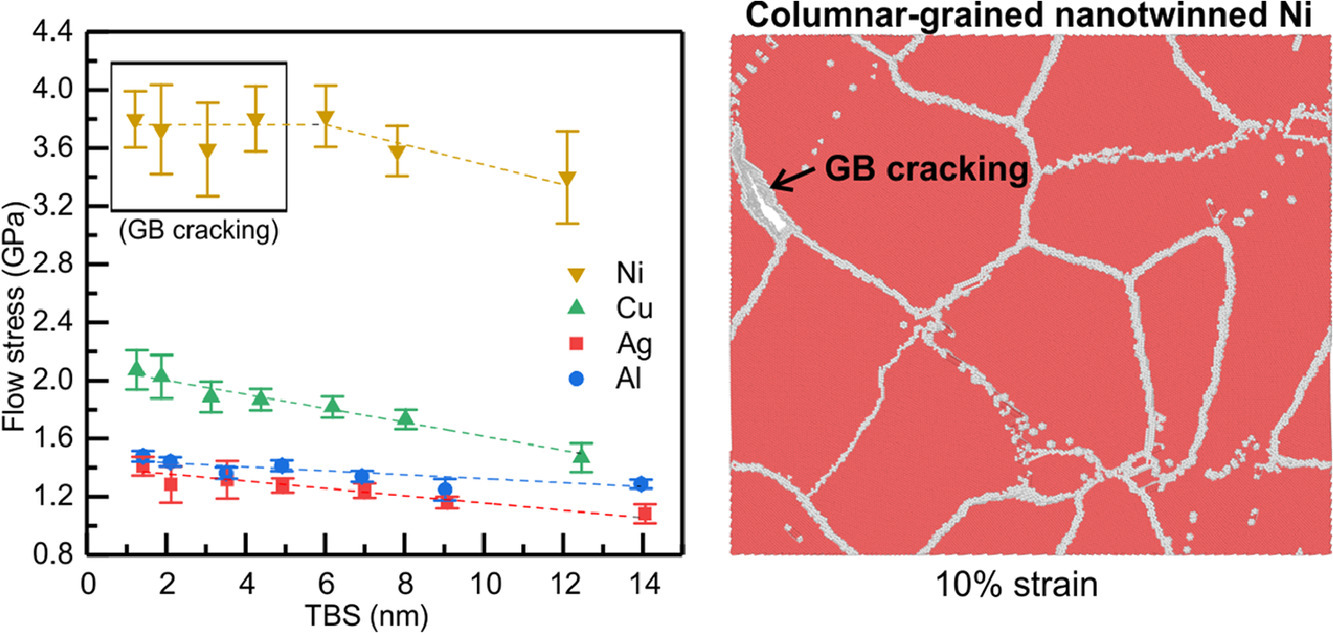

3. Columnar grain-driven plasticity and cracking in nanotwinned FCC metals

FCC納米孿晶柱狀晶的塑性與開裂

Qiongjiali Fanga, Frederic Sansoz?

F. Sansoz:frederic.sansoz@uvm.edu

https://doi.org/10.1016/j.actamat.2021.116925

摘要

研究者通常是從位錯角度對含有特定取向納米孿晶(nt)的柱狀晶強塑性機制進行研究,而很少從晶界(GB)變形的角度進行研究。我們采用了大尺度分子動力學模擬方法,研究了四種BCC納米孿晶柱狀晶(Cu、Ag、Al、Ni)中晶界應變調節對塑性變形的影響。結果表明,在平行于共格孿晶界(CTB)的拉伸變形中,金屬中的位錯機制相同,并且與小CTB間距下的晶界扭結發射和大CTB間距下的位錯纏結有關。隨著剪切模量的增加,柱狀晶孿晶金屬的CTB強化效果越來越明顯,這是由于GB應力集中與孿晶尺寸、金屬類型和應變速率有關。隨著CTB間距的減小,nt-Cu、nt-Ag和nt-Al的流動應力呈線性增加,而在nt-Ni在6 nm臨界CTB間距下達到最大強度極限。這一強度極限是由GB滑移引起的柱狀GB開裂造成的。對于柱狀晶組織,nt-Ag和nt-Al中的GB滑動相當,nt-Cu中稍低,nt-Ni中則非常顯著。以上發現強調了GB變形機制對柱狀晶nt金屬塑性和斷裂的影響,對于加深對FCC金屬中CTB強化的理解也有重要意義。

ACTA

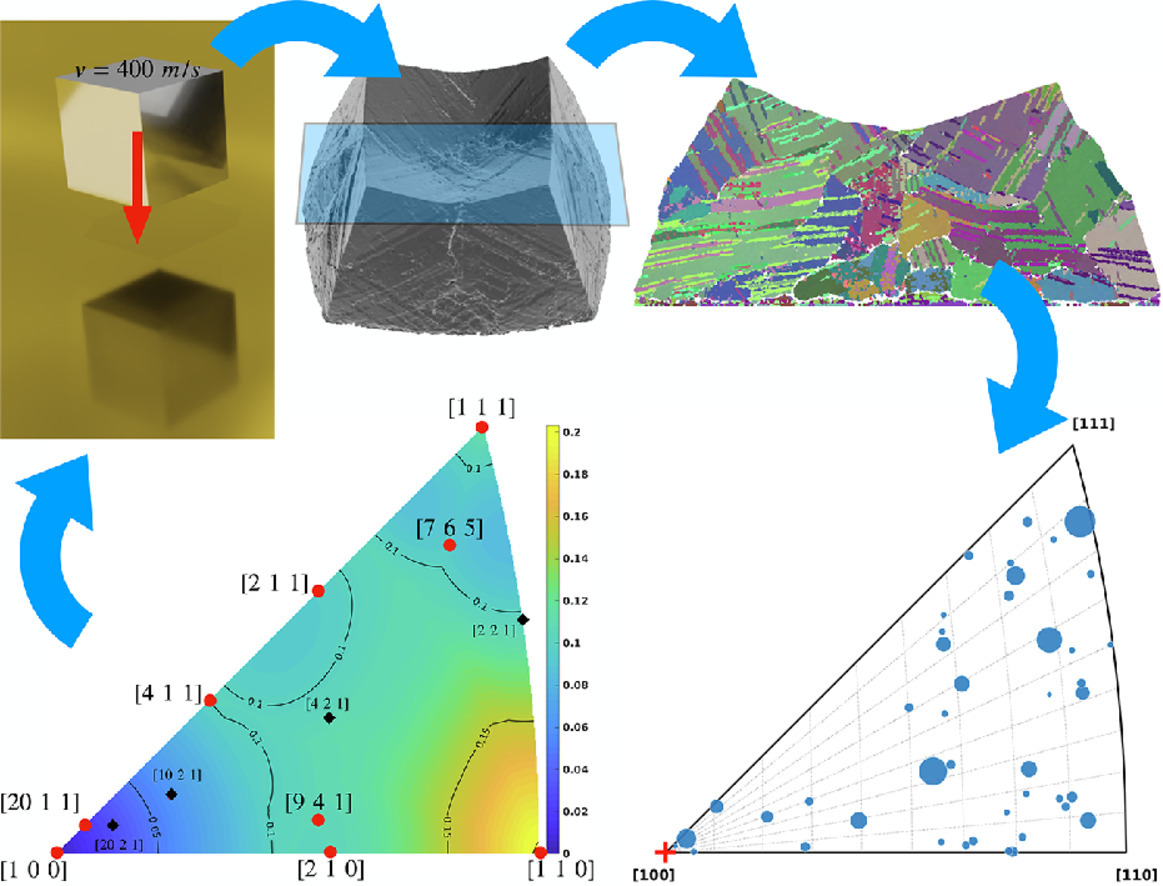

Vol. 212,15 Jun. 2021, 116892

4. Dynamic recrystallization of Silver nanocubes during high-velocity Impacts

銀納米立方體在高速沖擊下的動態再結晶

David Funes Rojas, Okan K. Orhan, Mauricio Ponga?

M. Ponga:mponga@mech.ubc.ca

https://doi.org/10.1016/j.actamat.2021.116892

摘要

我們通過分子動力學結合第一性原理計算,研究了銀(Ag)單晶納米立方體在高速沖擊下的組織演變、動態再結晶和沖擊后的晶格結構。我們的研究表明,在沖擊作用下,在某些取向上能夠形成由不同尺寸晶粒組成的復雜結構。這些取向的選擇對應于至少八個或更多滑移系統的同時激活和位錯雪崩。位錯相互作用,并能夠產生大量塑性變形促進納米立方中的再結晶。另一方面,對于不同時激活滑移系統的取向,則沒有觀察到動態再結晶。通過高溫下的第一性原理模擬,我們發現劇烈的塑性變形可以誘發面心立方結構向4H密排六方相的相變,而4H密排六方相比2H密排六方相在熱力學上更加穩定。這些結果與實驗結果吻合較好。我們的系統數值實驗揭示了促進動態再結晶的因素,并為在沖擊過程中通過取向調控材料的組織結構提供了指導。

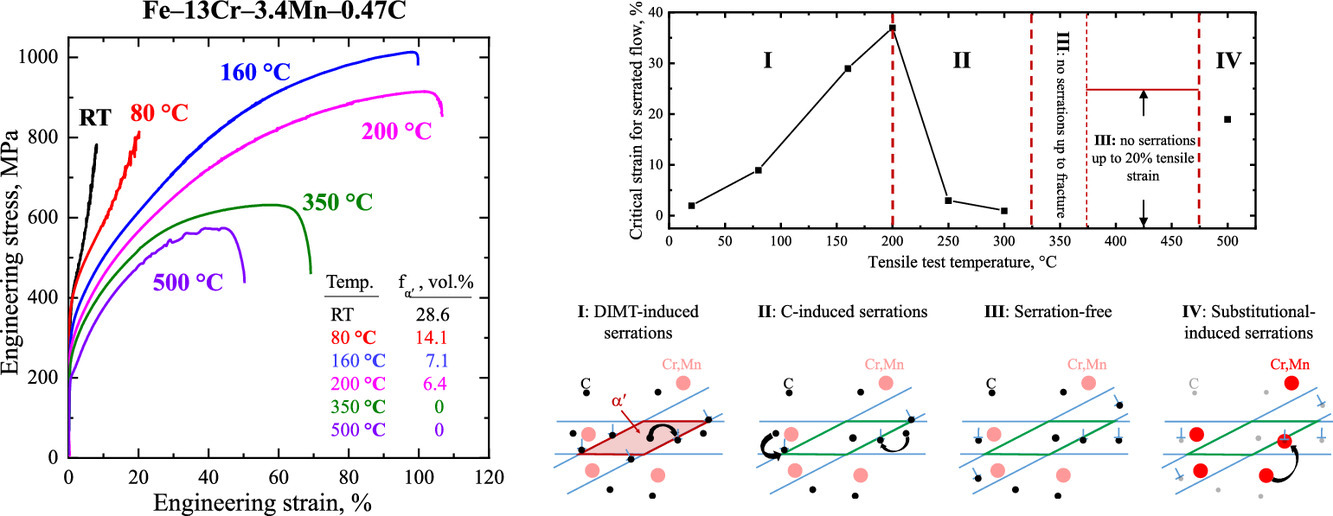

ACTA

Vol. 212,15 Jun. 2021, 116888

5. Dynamic strain aging mechanisms in a metastable austenitic stainless steel

亞穩奧氏體不銹鋼的動態應變時效機制研究

Javad Mola?, Guoqing Luan, Qiuliang Huang, Christiane Ullrich, Olena Volkova, Yuri Estrin

J. Mola:j.mola@hs-osnabrueck.de

https://doi.org/10.1016/j.actamat.2021.116888

摘要

我們采用單軸拉伸試驗對Fe-13Cr-3.4Mn-0.47C亞穩不銹鋼在20 ~ 500℃范圍內動態應變時效(DSA)引起的不連續塑性流變進行了研究。我們在已有模型上進行了改進,對中溫區的復雜不連續流變及其消失進行了解釋。不同溫度區間的DSA機制不同。200°C以下,DSA由滑移帶內的變形誘導馬氏體相變引起。這一過程中,馬氏體/奧氏體界面處的位錯不發生運動,且界面不斷向鄰近的奧氏體發射新的位錯。碳從馬氏體向馬氏體/奧氏體界面的快速擴散被認為是連續塑性流變中的一種釘扎機制。200-300°C區間內變形曲線上出現鋸齒,這與奧氏體中碳擴散引起的位錯釘扎有關。盡管在350-450°C,碳擴散速率增加,但此時無鋸齒現象,碳原子持續拖拽溶質元素。而在500°C時,由于發生鉻、錳原子對位錯的釘扎,因此鋸齒現象重新出現。

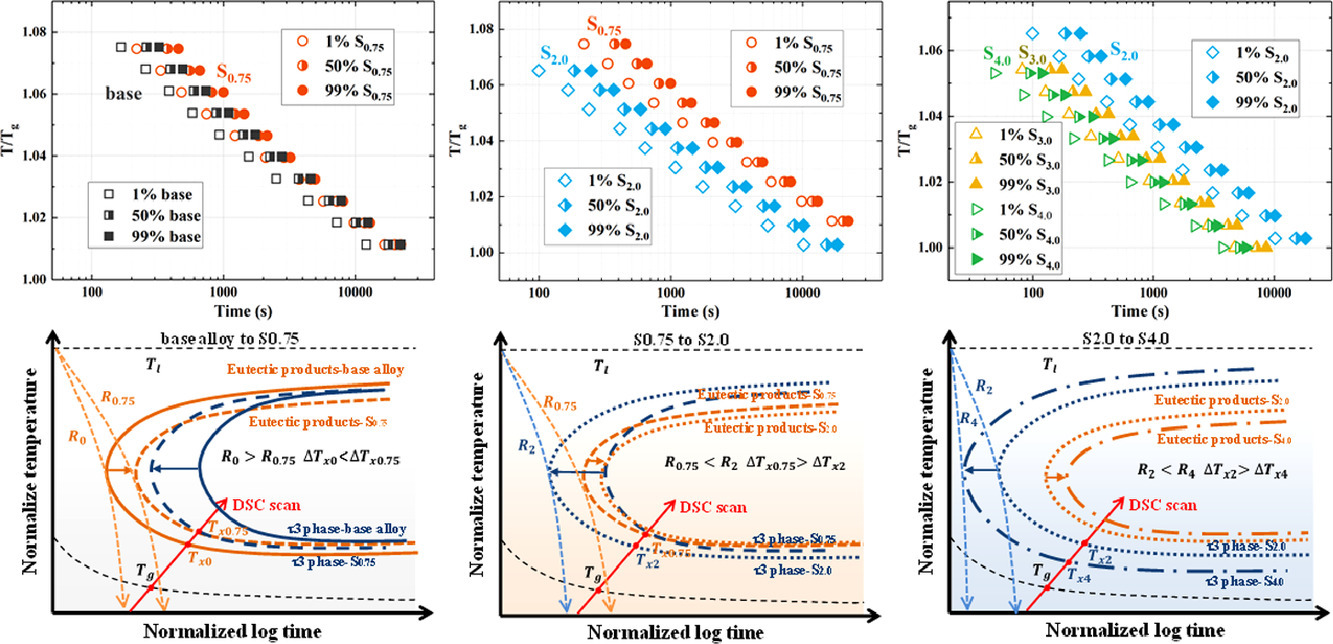

ACTA

Vol. 212,15 Jun. 2021, 116923

6. Effect of sulfur on the glass-forming ability, phase transformation, and thermal stability of Cu-Zr-Al bulk metallic glass

硫對Cu-Zr-Al塊體金屬玻璃形成能力、相變和熱穩定性的影響

Hao-Ran Jiang, Jing-Yi Hu, Nico Neuber, Benedikt Bochtler, Bastian Adam, Sascha S. Riegler, Maximilian Frey, Lucas Ruschel, Wen-Fei Lu, Ai-Han Feng?, Ralf Busch, Jun Shen?

A.-H. Feng:aihanfeng@tongji.edu.cn (同濟大學)

J. Shen:junshen@szu.edu.cn(深圳大學)

https://doi.org/10.1016/j.actamat.2021.116923

摘要

我們通過常規XRD、高能原位同步輻射XRD、SEM、熱差分析、熱力學分析等方法研究了少量添加硫對Cu47.5Zr45.1Al7.4塊體金屬玻璃(BMG)的玻璃形成能力(GFA)、相組成、熱穩定性和力學性能的影響。結果表明,硫對Cu-Zr-Al合金的GFA和熱穩定性同時具有正反兩方面的影響。一方面,硫可以減緩流體動力學,抑制熔體鑄造和玻璃加熱過程中共晶相析出,從而有利于含硫合金的玻璃相形成和熱穩定性。另一方面,硫的加入促進了富Al的τ3相的形成,對GFA和熔體穩定性具有顯著的負面效應。這兩個因素相互作用,使得Cu-Zr-Al合金中的最佳硫含量約為0.75at.%。與原合金相比,添加硫后材料具有更好的玻璃形成能力、更大的過冷液相區和優異的機械性能,是一種富有前景的工業結構材料。此外,我們根據實驗結果,闡明了時間-溫度-相變圖隨硫濃度的變化。

ACTA

Vol. 212,15 Jun. 2021, 116874

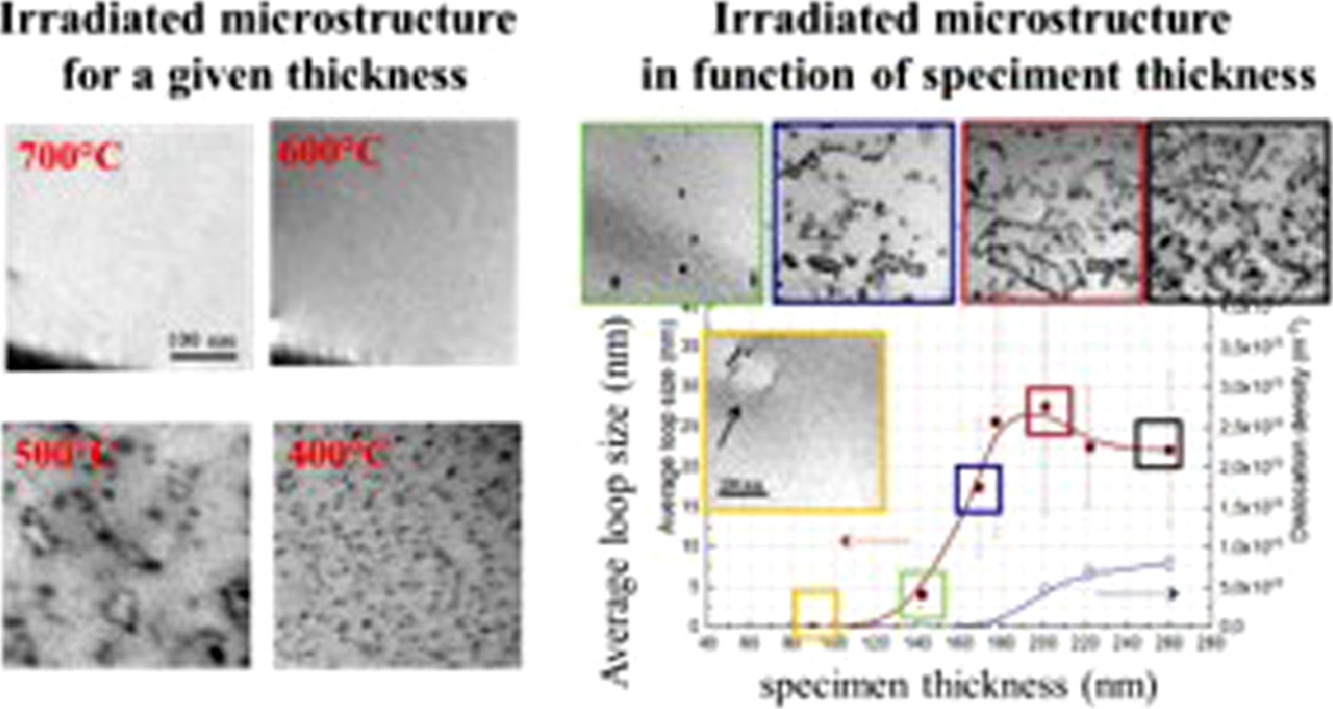

7. Free surface impact on radiation damage in pure nickel by in-situ self-ion irradiation: can it be avoided?

能否避免自由表面對純鎳原位自離子輻照損傷的影響?

Kan Ma, Brigitte Décamps, Anna Fraczkiewicz, Thomas Jourdan, Frédéric Prima, Marie Loyer-Prost?

M. Loyer-Prost:marie.loyer-prost@cea.fr

https://doi.org/10.1016/j.actamat.2021.116874

摘要

自由表面的表面效應是原位輻照損傷研究中的難點之一。因此,我們需要對表面效應進行詳細研究,從而對已有實驗結果進行驗證并為未來實驗提供指導。由于Ni中的自間隙原子具有較高的遷移率,因此我們選擇以Ni為對象對表面效應進行研究。我們采用2MeV的Ni2+離子在400-700°C下對超高純度Ni薄膜進行原位輻照。根據試樣厚度對位錯環的影響,對其進行了微觀組織演化分析和詳細表征。研究取得的成果包括:(i)厚度對組織演變和輻照效應影響顯著,且存在一個與溫度有關的臨界厚度;(ii)利用空位濃度計算模型很好地預測輻照厚度;(iii)自由表面對位錯環的Burgers矢量分布有影響;(iv)通過考慮無環區域隨溫度的變化確定了Ni中的空位遷移能;(v)我們首次在510°C觀察到,間隙原子減少10%有利于Ni中空位環的生長。

ACTA

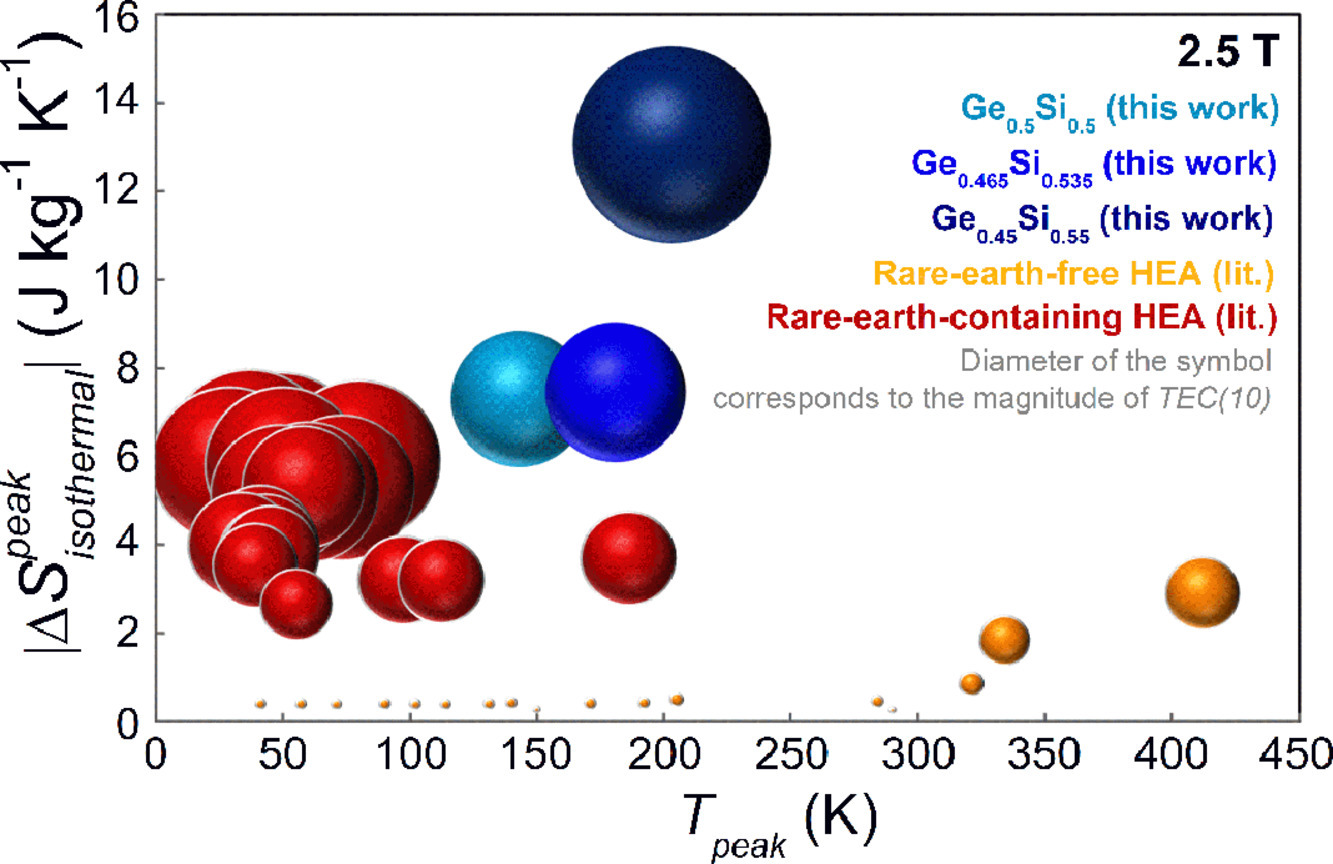

Vol. 212,15 Jun. 2021, 116931

8. Increased magnetocaloric response of FeMnNiGeSi high-entropy alloys

FeMnNiGeSi高熵合金的磁熱響應研究

Jia Yan Law?, Álvaro Díaz-García, Luis M. Moreno-Ramírez, Victorino Franco?

J.Y. Law:jylaw@us.es

V. Franco:vfranco@us.es

https://doi.org/10.1016/j.actamat.2021.116931

摘要

具有優異磁熱性能的高熵合金(HEAs)可能成為一種優異的功能材料。高熵合金的成分范圍很大,磁熱高熵合金通常在二級相變時表現出明顯的磁熱響應。本研究中,我們通過一種性能導向的搜索方法,發現多種具有不同Ge/Si比的FeMnNiGeSi高熵合金具有磁性結構一級相變。合金的等溫熵變最高可達13 J kg-1K-1 (2.5T條件下),這是迄今為止報道的具有最大磁熱效應的高熵合金。這一性能已能與許多傳統的磁熱材料體系相媲美。以上研究為具有優異力學性能的高熵合金功能材料設計提供了指導。

ACTA

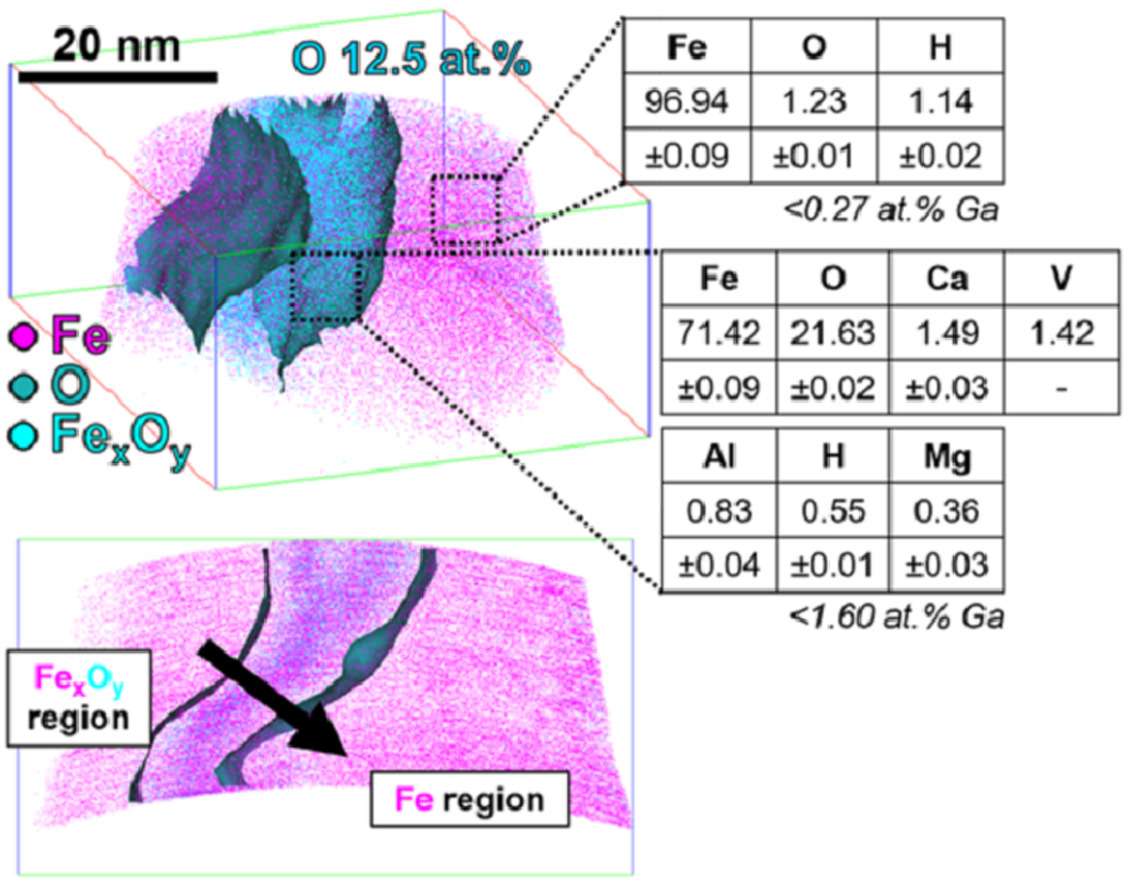

Vol. 212,15 Jun. 2021, 116933

9. Influence of microstructure and atomic-scale chemistry on the direct reduction of iron ore with hydrogen at 700°C

鐵礦石在700℃氫氣還原過程中的微觀結構和成分演化

Se-Ho Kim, Xue Zhang, Yan Ma, Isnaldi R. Souza Filho, Kevin Schweinar, Katja Angenendt, Dirk Vogel, Leigh T. Stephenson, Ayman A. El-Zoka, Jaber Rezaei Mianroodi, Michael Rohwerder, Baptiste Gault?, Dierk Raabe?

B. Gault:b.gault@mpie.de

D. Raabe:d.raabe@mpie.de

https://doi.org/10.1016/j.actamat.2021.116933

摘要

人們使用碳作為還原劑提煉礦石中的鐵,而鋼鐵冶煉目前已經是最大的單一工業溫室氣體排放源之一。因此,使用氫作還原劑具有廣闊的發展前景。盡管相關反應已經被研究了幾十年,但其動力學仍不清楚,且原慢過程及其緩慢。礦石的微觀結構和局部化學性質限制了反應速率。我們對采用純H2從赤鐵礦中煉鐵過程中礦石的結構和成分演變進行了研究。在還原過程中,由于氧的減少和非體積守恒相變,礦石中產生了復雜的孔隙和結構演變。還原后的高純鐵中含有孔隙和裂紋。我們觀察到了幾種晶格缺陷,這些缺陷對傳質有加速作用,以及多種雜質元素(Na, Mg, Ti, V)以未被還原的氧化物島形式存在。本研究對低碳鐵生產過程具有重要意義。

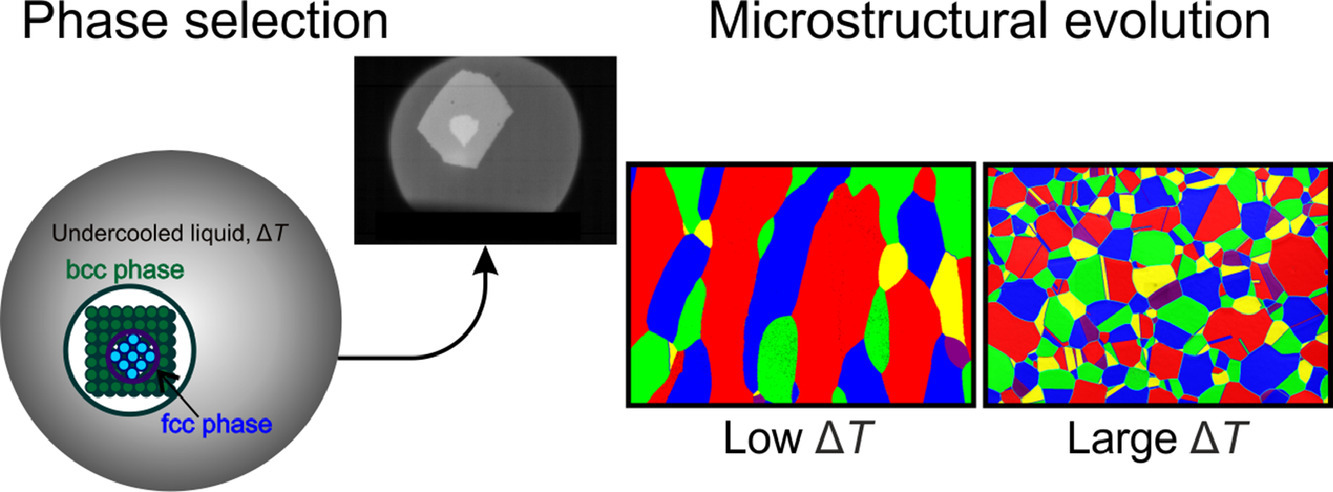

ACTA

Vol. 212,15 Jun. 2021, 116880

10. In situ study of non-equilibrium solidification of CoCrFeNi high-entropy alloy and CrFeNi and CoCrNi ternary suballoys

CoCrFeNi、CrFeNi和CoCrNi合金非平衡凝固的原位研究

Angelo F. Andreoli?, Olga Shuleshova, Victor T. Witusiewicz, Yuhao Wu, Yanzhao Yang, Oleh Ivashko, Ann-Christin Dippel, Martin v. Zimmermann, Kornelius Nielsch, Ivan Kaban?

A.F. Andreoli:a.fernandes.andreoli@ifw-dresden.de

I. Kaban:i.kaban@ifw-dresden.de

https://doi.org/10.1016/j.actamat.2021.116880

摘要

我們利用高速視頻和同步X射線衍射技術,對CoCrFeNi、CrFeNi和CoCrNi三種高熵/中熵合金的凝固行為進行了原位研究。在所有合金中,如果熔體過冷度較高,則可以觀察到初生亞穩BCC相的形成。穩定FCC相在BCC晶體中形核的孕育期與熔體過冷度成反比。相關的穩態和亞穩態相圖計算證實了實驗結果。基于高速視頻技術得到的CrFeNi、CoCrNi和CoCrFeNi晶體生長素體與文獻中Fe-Ni和Fe-Cr-Ni合金的數據相當,兩者具有相同的結晶動力學。此外,我們分析和討論了熔體過冷對凝固樣品組織的影響。

ACTA

Vol. 212,15 Jun. 2021, 116920

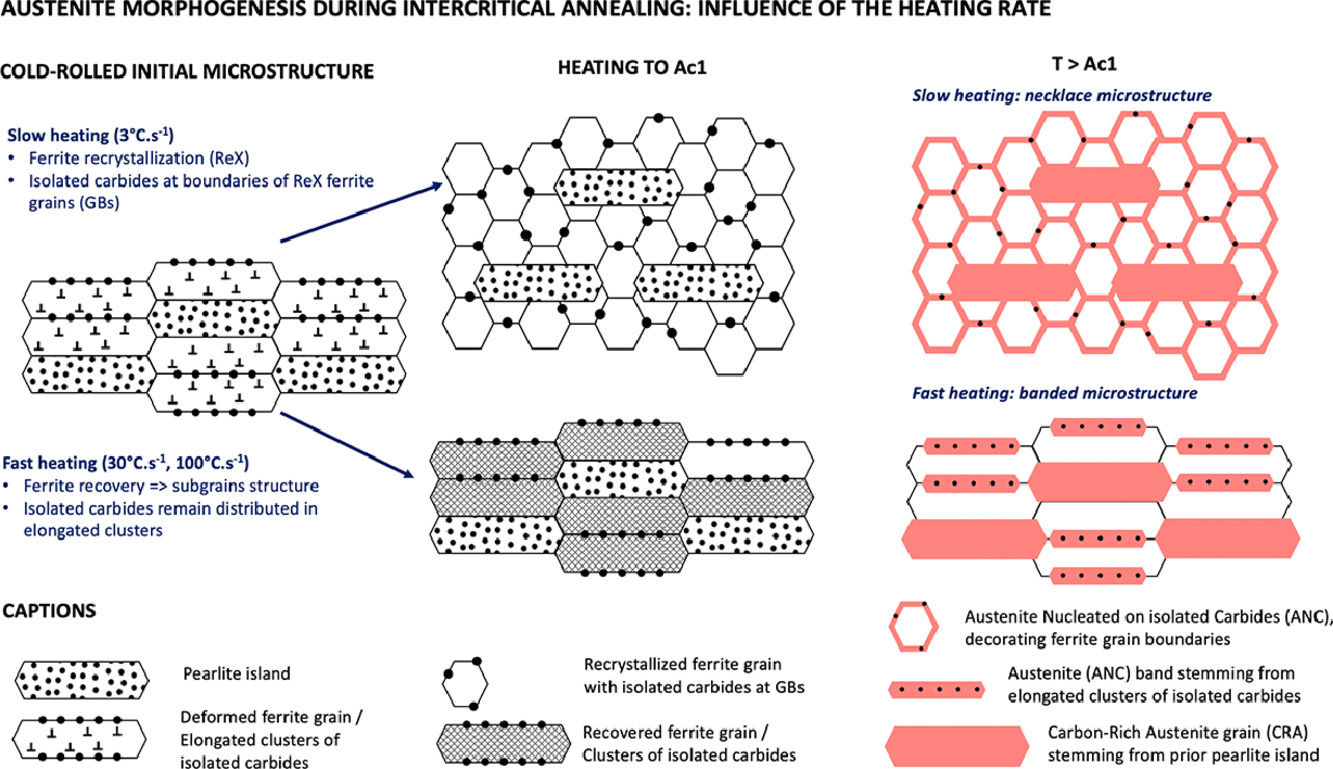

11. Intercritical annealing of cold-rolled ferrite-pearlite steel: Microstructure evolutions and phase transformation kinetics

冷軋珠光體-鐵素體鋼臨界退火過程中的組織演變和相變動力學研究

J. Teixeira?, M. Moreno?, S.Y.P. Allain?, C. Oberbillig?, G. Geandier?, F. Bonnet?

J. Teixeira:julien.teixeira@univ-lorraine.fr

M. Moreno:m_moreno@hotmail.fr

S.Y.P. Allain:sebastien.allain@univ-lorraine.fr

C. Oberbillig:carla.oberbillig@arcelormittal.com

G. Geandier:guillaume.geandier@univlorraine.fr

F. Bonnet:frederic.bonnet@arcelormittal.com

https://doi.org/10.1016/j.actamat.2021.116920

摘要

冷軋鐵素體珠光體(F/P)組織的退火是雙相鋼制備的關鍵步驟,涉及許多相互作用的機制,即鐵素體的回復/再結晶、球化、錳的富集、滲碳體的粗化和奧氏體相變。我們重點研究了奧氏體轉變,考慮了奧氏體與鐵素體再結晶的相互作用以及滲碳體化學成分的影響。我們通過組織觀察和原位高能X射線衍射研究了冷軋F/P組織在三種加熱速率下的演變,以闡明不同機制之間的相互作用。結果表明,奧氏體在緩慢加熱條件下呈鏈狀,而在快速加熱條件下呈帶狀。鐵素體基體中大量的晶間(或孤立的)碳化物是導致這種特殊的組織形貌的主要原因。這些碳化物是在熱軋過程中形成的。滲碳體成分的熱動力學分析表明,珠光體相變過程中發生置換型元素的配分。而孤立碳化物的溶解則在加熱過程中由配分型相變變為無配分相變。滲碳體溶解后,發生鐵素體-奧氏體相變,相變動力學隨加熱速率的增加而增加。我們通過DICTRA軟件對相變動力學進行了模擬和解釋。